What is Global 6-Axis CNC Press Brake Market?

The Global 6-Axis CNC Press Brake Market is a specialized segment within the broader machinery and equipment industry, focusing on advanced metal bending technology. A 6-axis CNC press brake is a machine tool used for bending sheet and plate material, most commonly sheet metal. It is equipped with a computer numerical control (CNC) system that allows for precise control over the bending process, utilizing six axes of movement to achieve complex bends and shapes. This technology is essential for industries that require high precision and efficiency in metal forming, such as automotive, aerospace, and manufacturing. The global market for these machines is driven by the increasing demand for high-quality, precision-engineered components, as well as the need for automation in manufacturing processes to improve productivity and reduce labor costs. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more efficient, user-friendly, and versatile machines to meet the evolving needs of various industries. As industries continue to seek ways to enhance their production capabilities, the demand for 6-axis CNC press brakes is expected to grow, making it a vital component of modern manufacturing infrastructure.

2500mm, 3200mm, 4100mm, Others in the Global 6-Axis CNC Press Brake Market:

The Global 6-Axis CNC Press Brake Market is segmented based on the size of the machines, which typically include 2500mm, 3200mm, 4100mm, and other dimensions. Each size category caters to different industrial needs and applications, offering varying levels of capacity and flexibility. The 2500mm press brake is often used in smaller manufacturing setups or for producing smaller components. Its compact size makes it ideal for workshops with limited space, yet it still offers the precision and efficiency required for high-quality metal bending. The 3200mm press brake is a mid-sized option that balances capacity and space requirements, making it suitable for medium-sized manufacturing operations. It provides a greater bending length, allowing for the production of larger components without compromising on precision. The 4100mm press brake is designed for large-scale industrial applications, offering the highest capacity and flexibility among the standard sizes. It is capable of handling large sheets of metal, making it ideal for industries such as automotive and aerospace, where large components are often required. Other sizes in the market cater to specific industrial needs, providing customized solutions for unique manufacturing challenges. These machines are often tailored to meet the specific requirements of a particular industry or application, offering specialized features and capabilities. The choice of machine size is influenced by several factors, including the type of material being processed, the complexity of the bending operations, and the production volume. Manufacturers must carefully consider these factors when selecting a press brake to ensure it meets their operational needs and provides the desired level of efficiency and precision. The availability of different sizes in the market allows manufacturers to choose a machine that best fits their specific requirements, optimizing their production processes and enhancing overall productivity. As the demand for precision-engineered components continues to grow across various industries, the need for versatile and efficient press brakes is expected to increase, driving further innovation and development in the market.

Sheet Metal Processing Plant, Home Appliance Manufacturing, Auto Parts, Others in the Global 6-Axis CNC Press Brake Market:

The Global 6-Axis CNC Press Brake Market plays a crucial role in various industries, particularly in sheet metal processing plants, home appliance manufacturing, auto parts production, and other sectors. In sheet metal processing plants, these machines are essential for bending and shaping metal sheets into desired forms, enabling the production of a wide range of components used in construction, machinery, and other applications. The precision and efficiency offered by 6-axis CNC press brakes make them indispensable in these settings, where high-quality and consistent output is critical. In the home appliance manufacturing industry, these machines are used to produce metal components for appliances such as refrigerators, ovens, and washing machines. The ability to create complex shapes and designs with high precision ensures that the components fit perfectly and function as intended, contributing to the overall quality and reliability of the finished products. In the automotive industry, 6-axis CNC press brakes are used to manufacture a variety of auto parts, including body panels, chassis components, and structural elements. The precision and flexibility of these machines allow for the production of complex shapes and designs that are essential for modern vehicles, where aerodynamics and aesthetics play a significant role. Other industries that benefit from the use of 6-axis CNC press brakes include aerospace, electronics, and furniture manufacturing. In aerospace, these machines are used to produce lightweight and durable components that meet the stringent safety and performance standards of the industry. In electronics, they are used to create enclosures and other components that require high precision and intricate designs. In furniture manufacturing, 6-axis CNC press brakes enable the production of metal frames and other components that contribute to the durability and aesthetic appeal of the finished products. The versatility and efficiency of these machines make them a valuable asset in any industry that requires precision metal forming, helping manufacturers improve their production processes and deliver high-quality products to their customers.

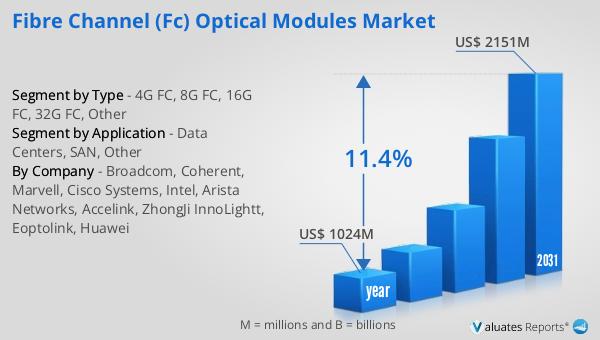

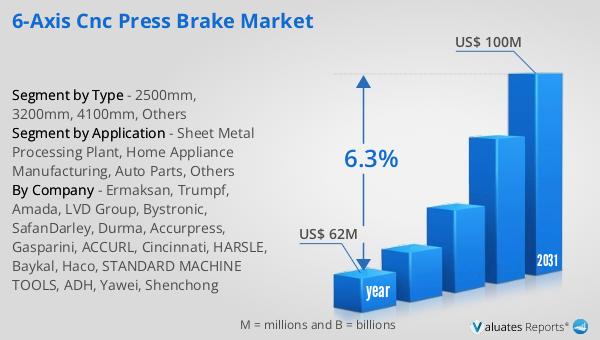

Global 6-Axis CNC Press Brake Market Outlook:

The global market for 6-axis CNC press brakes was valued at approximately $62 million in 2024, with projections indicating that it will grow to a revised size of around $100 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. This upward trend is driven by several factors, including the increasing demand for precision-engineered components across various industries and the need for automation in manufacturing processes. As industries continue to seek ways to enhance their production capabilities and improve efficiency, the adoption of advanced machinery like 6-axis CNC press brakes is expected to rise. These machines offer significant advantages in terms of precision, flexibility, and efficiency, making them an attractive investment for manufacturers looking to stay competitive in a rapidly evolving market. The growth of the market is also supported by continuous technological advancements, with manufacturers focusing on developing more efficient, user-friendly, and versatile machines to meet the evolving needs of various industries. As the demand for high-quality, precision-engineered components continues to grow, the market for 6-axis CNC press brakes is expected to expand, providing opportunities for manufacturers to innovate and develop new solutions to meet the needs of their customers.

| Report Metric | Details |

| Report Name | 6-Axis CNC Press Brake Market |

| Accounted market size in year | US$ 62 million |

| Forecasted market size in 2031 | US$ 100 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ermaksan, Trumpf, Amada, LVD Group, Bystronic, SafanDarley, Durma, Accurpress, Gasparini, ACCURL, Cincinnati, HARSLE, Baykal, Haco, STANDARD MACHINE TOOLS, ADH, Yawei, Shenchong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |