What is Global Vehicle Suspension Tester Market?

The Global Vehicle Suspension Tester Market is a specialized segment within the automotive industry that focuses on the development and distribution of equipment designed to test the suspension systems of vehicles. These testers are crucial for assessing the performance and safety of a vehicle's suspension, which is responsible for maintaining ride quality and handling. The market encompasses a variety of products, including both portable and stationary testers, which are used by automotive manufacturers, repair shops, and inspection centers. The demand for vehicle suspension testers is driven by the increasing emphasis on vehicle safety and performance, as well as regulatory requirements for regular vehicle inspections. As vehicles become more advanced, with complex suspension systems, the need for precise and reliable testing equipment grows. This market is characterized by technological advancements, with manufacturers continually innovating to provide more accurate and efficient testing solutions. The global reach of this market is evident as it serves a diverse range of customers across different regions, each with unique requirements and standards. The growth of the Global Vehicle Suspension Tester Market is indicative of the broader trends in the automotive industry towards enhanced safety, performance, and regulatory compliance.

in the Global Vehicle Suspension Tester Market:

In the Global Vehicle Suspension Tester Market, various types of testers are utilized by different customers based on their specific needs and applications. One of the primary types is the portable suspension tester, which is favored by smaller repair shops and mobile service providers due to its convenience and ease of use. These testers are compact and can be easily transported, making them ideal for on-site inspections and repairs. They are designed to provide quick and accurate assessments of a vehicle's suspension system, allowing technicians to diagnose issues and recommend necessary repairs. Another popular type is the stationary suspension tester, which is commonly used in larger automotive service centers and inspection facilities. These testers are typically more robust and capable of handling a higher volume of vehicles. They are often integrated into a larger diagnostic system, providing comprehensive testing capabilities that include not only suspension but also other critical vehicle systems. Stationary testers are valued for their precision and ability to conduct thorough inspections, making them essential for facilities that perform regular vehicle inspections and certifications. Additionally, there are advanced suspension testers equipped with digital interfaces and software integration, allowing for detailed data analysis and reporting. These testers are particularly useful for automotive manufacturers and research institutions that require in-depth analysis of suspension performance for development and testing purposes. The digital capabilities enable users to track performance metrics over time, identify trends, and make data-driven decisions to enhance vehicle design and safety. Furthermore, some testers are designed specifically for certain types of vehicles, such as heavy-duty trucks or high-performance sports cars, catering to the unique suspension characteristics and testing requirements of these vehicles. The diversity in tester types reflects the varied needs of customers in the Global Vehicle Suspension Tester Market, with each type offering distinct advantages and features tailored to specific applications. As the market continues to evolve, manufacturers are likely to introduce even more specialized and advanced testing solutions to meet the growing demands of the automotive industry.

Vehicle Inspection, Vehicle Repair, Others in the Global Vehicle Suspension Tester Market:

The usage of Global Vehicle Suspension Tester Market products spans several key areas, including vehicle inspection, vehicle repair, and other applications. In the realm of vehicle inspection, suspension testers play a critical role in ensuring that vehicles meet safety and performance standards. Inspection centers utilize these testers to conduct routine checks on a vehicle's suspension system, identifying any issues that could compromise safety or handling. This is particularly important in regions with strict regulatory requirements for vehicle inspections, where suspension testers help ensure compliance and roadworthiness. By providing accurate and reliable assessments, these testers contribute to the overall safety of the driving public. In vehicle repair, suspension testers are indispensable tools for diagnosing and addressing suspension-related issues. Repair shops rely on these testers to pinpoint problems within the suspension system, such as worn-out components or misalignments, which can affect ride quality and vehicle stability. By accurately identifying the root cause of suspension problems, technicians can perform targeted repairs, improving the efficiency and effectiveness of the repair process. This not only enhances customer satisfaction but also reduces the likelihood of repeat issues, as repairs are based on precise diagnostics. Beyond inspection and repair, suspension testers are also used in other applications, such as research and development within the automotive industry. Manufacturers and research institutions utilize these testers to evaluate the performance of new suspension designs and materials, ensuring that they meet desired specifications and performance criteria. This is crucial for the development of innovative suspension systems that enhance vehicle safety, comfort, and handling. Additionally, suspension testers are used in educational settings, providing students and trainees with hands-on experience in vehicle diagnostics and maintenance. By familiarizing future technicians and engineers with suspension testing equipment, educational institutions help prepare them for careers in the automotive industry. Overall, the usage of Global Vehicle Suspension Tester Market products is integral to maintaining vehicle safety, performance, and innovation across various sectors.

Global Vehicle Suspension Tester Market Outlook:

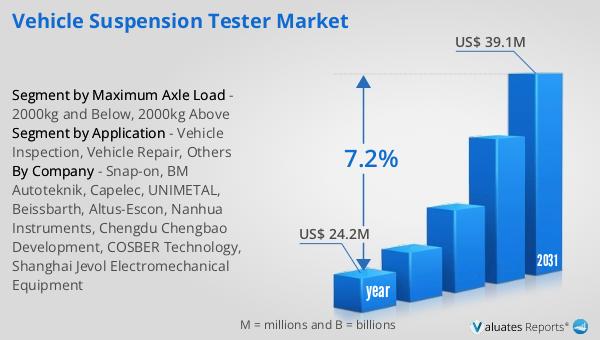

The global market for Vehicle Suspension Tester was valued at $24.2 million in 2024 and is anticipated to expand to a revised size of $39.1 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.2% during the forecast period. This growth trajectory underscores the increasing demand for vehicle suspension testers, driven by factors such as heightened safety standards, technological advancements, and the growing complexity of modern vehicles. As automotive manufacturers and service providers strive to meet stringent regulatory requirements and consumer expectations, the need for precise and reliable suspension testing equipment becomes more pronounced. The projected growth of the market indicates a robust demand for these testers across various regions, with each market segment contributing to the overall expansion. The rising adoption of advanced suspension systems in vehicles, coupled with the emphasis on vehicle safety and performance, is expected to fuel the demand for suspension testers. Additionally, the integration of digital technologies and data analytics in suspension testing equipment is likely to enhance their functionality and appeal to a broader range of customers. As the market evolves, manufacturers are poised to introduce innovative solutions that cater to the diverse needs of the automotive industry, further driving the growth of the Global Vehicle Suspension Tester Market.

| Report Metric | Details |

| Report Name | Vehicle Suspension Tester Market |

| Accounted market size in year | US$ 24.2 million |

| Forecasted market size in 2031 | US$ 39.1 million |

| CAGR | 7.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Maximum Axle Load |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Snap-on, BM Autoteknik, Capelec, UNIMETAL, Beissbarth, Altus-Escon, Nanhua Instruments, Chengdu Chengbao Development, COSBER Technology, Shanghai Jevol Electromechanical Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |