What is Global Vehicle Suspension Test Bench Market?

The Global Vehicle Suspension Test Bench Market is a specialized segment within the automotive industry that focuses on the testing and analysis of vehicle suspension systems. These test benches are essential tools used by manufacturers, repair shops, and inspection facilities to evaluate the performance, durability, and safety of suspension components. The market for these test benches is driven by the increasing demand for vehicle safety and performance optimization. As vehicles become more advanced, with complex suspension systems designed to enhance ride comfort and handling, the need for precise testing equipment becomes critical. These test benches simulate real-world driving conditions, allowing engineers to assess how suspension systems respond to various stresses and loads. This data is crucial for improving vehicle design, ensuring compliance with safety standards, and enhancing overall driving experience. The market is characterized by a range of products, from basic models for routine inspections to advanced systems capable of detailed analysis and diagnostics. As automotive technology continues to evolve, the Global Vehicle Suspension Test Bench Market is expected to grow, driven by innovations in testing methodologies and the increasing complexity of vehicle suspension systems.

in the Global Vehicle Suspension Test Bench Market:

In the Global Vehicle Suspension Test Bench Market, various types of test benches are utilized by different customers based on their specific needs and applications. One of the most common types is the hydraulic suspension test bench, which uses hydraulic actuators to simulate road conditions and assess the performance of suspension systems. These benches are favored for their ability to replicate a wide range of driving scenarios, making them ideal for manufacturers who need to test new suspension designs under various conditions. Another popular type is the pneumatic suspension test bench, which uses compressed air to apply loads and simulate road conditions. These benches are often used in environments where hydraulic systems might be impractical, offering a cleaner and more environmentally friendly alternative. Additionally, there are electromechanical suspension test benches, which use electric motors to generate the necessary forces for testing. These benches are known for their precision and control, making them suitable for detailed analysis and research applications. Customers in the automotive industry, such as vehicle manufacturers, rely on these test benches to ensure that their suspension systems meet safety and performance standards. Repair shops and service centers also use these benches to diagnose and fix suspension-related issues, ensuring that vehicles remain safe and comfortable to drive. Furthermore, inspection facilities utilize suspension test benches to verify that vehicles comply with regulatory requirements, providing an additional layer of safety assurance for consumers. Each type of test bench offers unique advantages, and the choice of which to use often depends on factors such as the specific testing requirements, budget constraints, and environmental considerations. As the automotive industry continues to advance, the demand for diverse and sophisticated suspension test benches is expected to grow, driven by the need for improved vehicle safety, performance, and compliance with increasingly stringent regulations.

Vehicle Inspection, Vehicle Repair, Others in the Global Vehicle Suspension Test Bench Market:

The Global Vehicle Suspension Test Bench Market finds its usage in several key areas, including vehicle inspection, vehicle repair, and other specialized applications. In the realm of vehicle inspection, suspension test benches play a crucial role in ensuring that vehicles meet safety and performance standards. Inspection facilities use these benches to simulate driving conditions and assess the condition of a vehicle's suspension system. This process helps identify any potential issues that could affect the vehicle's safety or performance, allowing for timely repairs and maintenance. By providing accurate and reliable data, suspension test benches help ensure that vehicles on the road are safe and compliant with regulatory standards. In vehicle repair, suspension test benches are invaluable tools for diagnosing and fixing suspension-related problems. Repair shops use these benches to simulate road conditions and identify issues such as worn-out components, misalignments, or imbalances in the suspension system. This information is critical for technicians to perform accurate repairs and ensure that the vehicle's suspension system is functioning optimally. By using suspension test benches, repair shops can provide high-quality service and improve customer satisfaction by ensuring that vehicles are safe and comfortable to drive. Beyond inspection and repair, suspension test benches are also used in research and development, where they help engineers design and test new suspension systems. These benches allow for detailed analysis and testing of suspension components, enabling manufacturers to develop innovative solutions that enhance vehicle performance and safety. As the automotive industry continues to evolve, the use of suspension test benches in these areas is expected to grow, driven by the increasing complexity of vehicle suspension systems and the need for precise testing and analysis.

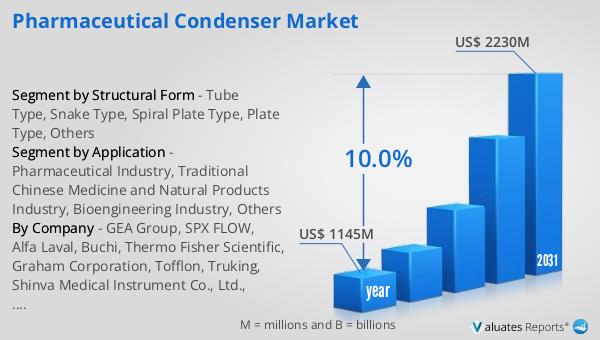

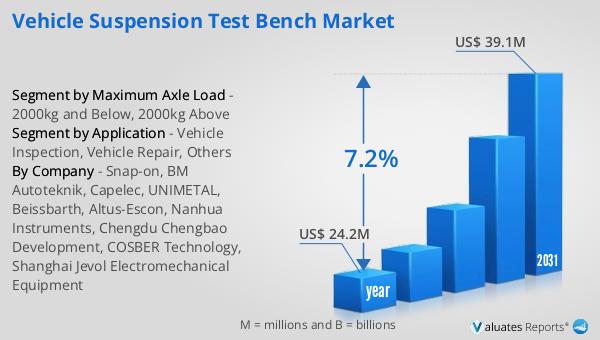

Global Vehicle Suspension Test Bench Market Outlook:

The global market for Vehicle Suspension Test Bench was valued at $24.2 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $39.1 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.2% over the forecast period. The increasing demand for advanced testing equipment in the automotive industry is a key driver of this market expansion. As vehicles become more sophisticated, with complex suspension systems designed to improve ride comfort and handling, the need for precise and reliable testing equipment becomes more critical. Manufacturers, repair shops, and inspection facilities are investing in advanced suspension test benches to ensure that their vehicles meet safety and performance standards. This trend is further supported by the growing emphasis on vehicle safety and the need for compliance with stringent regulatory requirements. The market is characterized by a range of products, from basic models for routine inspections to advanced systems capable of detailed analysis and diagnostics. As the automotive industry continues to advance, the Global Vehicle Suspension Test Bench Market is expected to grow, driven by innovations in testing methodologies and the increasing complexity of vehicle suspension systems. This growth presents significant opportunities for manufacturers and suppliers of suspension test benches, as they seek to meet the evolving needs of the automotive industry.

| Report Metric | Details |

| Report Name | Vehicle Suspension Test Bench Market |

| Accounted market size in year | US$ 24.2 million |

| Forecasted market size in 2031 | US$ 39.1 million |

| CAGR | 7.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Maximum Axle Load |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Snap-on, BM Autoteknik, Capelec, UNIMETAL, Beissbarth, Altus-Escon, Nanhua Instruments, Chengdu Chengbao Development, COSBER Technology, Shanghai Jevol Electromechanical Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |