What is Global Vacuum Lamination Equipment Market?

The Global Vacuum Lamination Equipment Market is a specialized segment within the broader industrial machinery sector, focusing on equipment designed to laminate materials under vacuum conditions. This process is crucial in various high-tech manufacturing industries, where precision and quality are paramount. Vacuum lamination involves the application of pressure and heat in a vacuum environment to bond layers of materials, ensuring a uniform and defect-free finish. This technology is widely used in the production of electronic components, solar panels, and other advanced materials that require meticulous assembly processes. The market for vacuum lamination equipment is driven by the increasing demand for high-performance electronic devices and the growing adoption of renewable energy solutions. As industries continue to innovate and push the boundaries of technology, the need for reliable and efficient lamination equipment becomes even more critical. Companies operating in this market are continually investing in research and development to enhance the capabilities of their equipment, offering solutions that cater to the evolving needs of their clients. The global reach of this market underscores its importance, with significant contributions from regions such as Asia-Pacific, North America, and Europe.

Fully Automatic, Semi-automatic in the Global Vacuum Lamination Equipment Market:

In the Global Vacuum Lamination Equipment Market, the distinction between fully automatic and semi-automatic machines is significant, as each type caters to different operational needs and production scales. Fully automatic vacuum lamination equipment is designed for high-volume production environments where efficiency and precision are critical. These machines are equipped with advanced control systems that automate the entire lamination process, from material loading to final product output. The automation reduces the need for manual intervention, minimizing human error and ensuring consistent quality across large batches. Fully automatic systems are ideal for industries such as semiconductor manufacturing and large-scale electronics production, where the demand for precision and speed is high. These machines often come with features like real-time monitoring, automatic adjustments, and integration with other production line systems, making them a preferred choice for companies looking to optimize their manufacturing processes. On the other hand, semi-automatic vacuum lamination equipment offers a balance between automation and manual control. These machines are suitable for smaller production runs or specialized applications where flexibility is more important than speed. Semi-automatic systems require some level of operator involvement, particularly in the setup and monitoring stages, allowing for greater control over the lamination process. This can be advantageous in scenarios where customization or handling of delicate materials is necessary. While they may not match the throughput of fully automatic systems, semi-automatic machines provide a cost-effective solution for businesses that do not require high-volume production capabilities. The choice between fully automatic and semi-automatic equipment often depends on factors such as production volume, budget constraints, and the specific requirements of the end product. Companies must carefully evaluate their operational needs and long-term goals to determine the most suitable type of equipment for their manufacturing processes. As technology continues to advance, both fully automatic and semi-automatic vacuum lamination equipment are expected to evolve, offering enhanced features and capabilities to meet the diverse needs of the global market.

Semiconductor Wafer, PCB, Others in the Global Vacuum Lamination Equipment Market:

The Global Vacuum Lamination Equipment Market finds extensive application in several key areas, including semiconductor wafer production, printed circuit boards (PCBs), and other specialized fields. In the semiconductor industry, vacuum lamination equipment is crucial for the fabrication of wafers, which are the foundational components of electronic devices. The precision and quality required in semiconductor manufacturing make vacuum lamination an essential process, ensuring that the layers of materials are bonded without defects or impurities. This is vital for the performance and reliability of the final semiconductor products, which are used in a wide range of applications from consumer electronics to advanced computing systems. In the realm of printed circuit boards, vacuum lamination equipment plays a pivotal role in the assembly of multilayer PCBs. These boards are integral to modern electronic devices, providing the necessary connections and pathways for electrical signals. The lamination process ensures that the multiple layers of the PCB are securely bonded, maintaining the integrity and functionality of the board. This is particularly important as electronic devices become more compact and complex, requiring PCBs that can support higher densities of components and connections. Beyond semiconductors and PCBs, vacuum lamination equipment is also used in other industries where high-quality bonding is required. This includes the production of solar panels, where vacuum lamination ensures the durability and efficiency of the photovoltaic cells. Additionally, the equipment is used in the manufacturing of advanced materials and composites, which are employed in industries such as aerospace, automotive, and renewable energy. These applications highlight the versatility and importance of vacuum lamination equipment in supporting the development and production of cutting-edge technologies. As industries continue to innovate and demand higher performance from their products, the role of vacuum lamination equipment in ensuring quality and precision will remain critical.

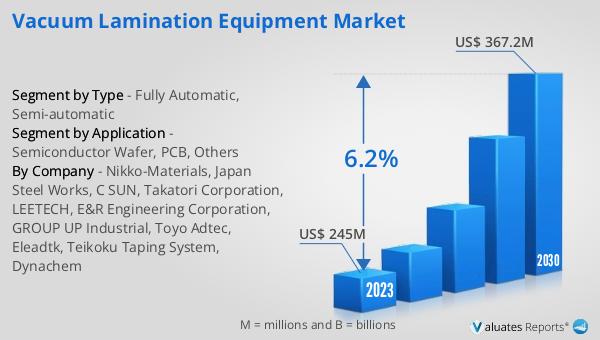

Global Vacuum Lamination Equipment Market Outlook:

The global market for vacuum lamination equipment was valued at $271 million in 2024 and is anticipated to grow to $409 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. The market is dominated by the top five players, who collectively hold approximately 73% of the market share. The Asia-Pacific region emerges as the largest market, accounting for about 61% of the global share, followed by North America and Europe, which hold 21% and 12% respectively. In terms of product type, fully automatic vacuum lamination equipment represents the largest segment, comprising over 85% of the market share. This dominance is attributed to the high demand for efficiency and precision in large-scale production environments. Meanwhile, in terms of application, the semiconductor wafer sector is the largest downstream field, capturing over 50% of the market share. This highlights the critical role of vacuum lamination equipment in the semiconductor industry, where precision and quality are paramount. The market dynamics underscore the importance of technological advancements and regional contributions in shaping the future of the vacuum lamination equipment industry.

| Report Metric | Details |

| Report Name | Vacuum Lamination Equipment Market |

| Accounted market size in year | US$ 271 million |

| Forecasted market size in 2031 | US$ 409 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nikko-Materials, Japan Steel Works, C SUN, Takatori Corporation, LEETECH, E&R Engineering Corporation, GROUP UP Industrial, Toyo Adtec, Eleadtk, Teikoku Taping System, Dynachem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |