What is Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market?

The Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market is a specialized segment within the broader electrical components industry. This market focuses on the production and distribution of electrical contacts and assemblies that are composed of a unique combination of silver, tungsten carbide, and graphite. These materials are chosen for their exceptional electrical conductivity, durability, and resistance to wear and tear, making them ideal for use in various electrical applications. Silver provides excellent conductivity, tungsten carbide offers hardness and resistance to high temperatures, and graphite contributes to lubrication and thermal stability. Together, these materials create a composite that is highly effective in demanding electrical environments. The market for these products is driven by the increasing demand for reliable and efficient electrical components in industries such as automotive, aerospace, and energy. As technology advances and the need for high-performance electrical systems grows, the demand for silver tungsten carbide graphite electrical contacts and assemblies is expected to rise. This market is characterized by continuous innovation and development to meet the evolving needs of various industries, ensuring that these components remain at the forefront of electrical technology.

Below 70%, 70%-80%, Above 80% in the Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market:

In the Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market, the composition of the materials used can vary, leading to different performance characteristics and cost implications. The market is typically segmented into three categories based on the percentage composition of silver: Below 70%, 70%-80%, and Above 80%. Each category offers distinct advantages and is suited for specific applications. The Below 70% category is often chosen for applications where cost-effectiveness is a priority. By reducing the silver content, manufacturers can lower production costs while still maintaining adequate performance for less demanding applications. This category is ideal for industries where budget constraints are significant, and the electrical demands are moderate. The 70%-80% category strikes a balance between cost and performance. With a higher silver content, these contacts and assemblies offer improved conductivity and durability compared to the Below 70% category. This makes them suitable for applications that require a higher level of reliability and efficiency, such as in medium-duty electrical systems. The Above 80% category represents the premium segment of the market. With the highest silver content, these contacts and assemblies provide superior electrical conductivity and resistance to wear and tear. They are designed for the most demanding applications, where performance and longevity are critical. Industries such as aerospace and high-end automotive manufacturing often rely on these high-performance components to ensure optimal functionality and safety. The choice between these categories depends on the specific requirements of the application, including factors such as electrical load, environmental conditions, and budget constraints. Manufacturers and end-users must carefully consider these factors to select the appropriate composition that meets their needs. As the market continues to evolve, advancements in material science and manufacturing techniques are expected to further enhance the performance and cost-effectiveness of these electrical contacts and assemblies, providing even more options for various industries.

DC Switching Equipment, MCB, Heavy Duty Relay, Others in the Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market:

The Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market finds its applications in several key areas, including DC Switching Equipment, Miniature Circuit Breakers (MCB), Heavy Duty Relays, and other specialized electrical systems. In DC Switching Equipment, these contacts and assemblies play a crucial role in ensuring reliable and efficient operation. The unique combination of materials provides excellent conductivity and durability, which are essential for handling the high currents and voltages typically associated with DC systems. The ability to withstand arcing and resist wear and tear makes these components ideal for use in DC switching applications, where reliability and longevity are paramount. In Miniature Circuit Breakers (MCB), silver tungsten carbide graphite contacts and assemblies are used to ensure quick and efficient interruption of electrical circuits in the event of an overload or short circuit. The high conductivity and thermal stability of these materials allow for rapid response times, minimizing the risk of damage to electrical systems and enhancing safety. The durability of these components also ensures a long service life, reducing the need for frequent replacements and maintenance. Heavy Duty Relays benefit from the use of these advanced electrical contacts and assemblies due to their ability to handle high electrical loads and resist mechanical wear. The combination of silver, tungsten carbide, and graphite provides the necessary strength and conductivity to ensure reliable operation in demanding environments. These components are often used in industrial and automotive applications, where they must withstand harsh conditions and frequent switching operations. Other applications of silver tungsten carbide graphite electrical contacts and assemblies include specialized electrical systems in industries such as aerospace, energy, and telecommunications. In these areas, the need for high-performance and reliable electrical components is critical, and the unique properties of these materials make them an ideal choice. As technology continues to advance and the demand for efficient and reliable electrical systems grows, the use of these advanced materials is expected to expand, driving further innovation and development in the market.

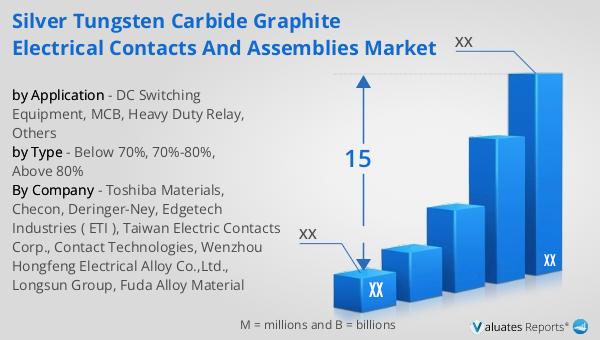

Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market Outlook:

In the market outlook for the Global Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market, a notable development is the addition of a copper layer to form AgWCC/Cu contacts. This innovation allows for a significant reduction in production costs, ranging from 15% to 30%, without compromising the performance of the product. By integrating copper, manufacturers can achieve a more cost-effective solution while maintaining the high conductivity and durability that these contacts are known for. This advancement is particularly beneficial in industries where cost efficiency is a priority, enabling broader adoption of these advanced electrical components. In terms of regional market growth, the North American market for Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies is projected to experience significant expansion. Starting from an estimated value in 2024, the market is expected to reach a higher valuation by 2031, driven by a compound annual growth rate (CAGR) over the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for high-performance electrical components in the region, fueled by advancements in technology and the need for reliable and efficient electrical systems across various industries. As the market continues to evolve, innovations such as the AgWCC/Cu contacts are likely to play a crucial role in shaping the future landscape of the industry, offering new opportunities for growth and development.

| Report Metric | Details |

| Report Name | Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies Market |

| CAGR | 15 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toshiba Materials, Checon, Deringer-Ney, Edgetech Industries ( ETI ), Taiwan Electric Contacts Corp., Contact Technologies, Wenzhou Hongfeng Electrical Alloy Co.,Ltd., Longsun Group, Fuda Alloy Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |