What is Global Prototype Injection Molding Service Market?

The Global Prototype Injection Molding Service Market is a specialized sector within the broader manufacturing industry that focuses on creating prototype models using injection molding techniques. This market is essential for industries that require rapid prototyping to test and refine product designs before mass production. Prototype injection molding involves creating molds that can produce a limited number of parts, allowing companies to evaluate the design, functionality, and manufacturability of a product. This service is crucial for reducing the time and cost associated with product development, as it enables companies to identify and rectify design flaws early in the process. The market caters to various industries, including automotive, aerospace, medical, consumer goods, and electronics, each with unique requirements and standards. As technology advances, the demand for more precise and efficient prototyping methods continues to grow, driving innovation within the market. Companies offering these services must stay abreast of the latest technological developments and industry trends to remain competitive. The global reach of this market means that service providers must also navigate different regulatory environments and customer expectations across regions. Overall, the Global Prototype Injection Molding Service Market plays a pivotal role in modern manufacturing, facilitating innovation and efficiency in product development.

Rapid Prototyping, Insert Molding, High-temperature Molding, Thin-wall Molding, Multi-cavity Molding, Others in the Global Prototype Injection Molding Service Market:

Rapid prototyping is a key component of the Global Prototype Injection Molding Service Market, allowing for the quick creation of scale models using computer-aided design (CAD) data. This process is invaluable for testing and refining product designs, enabling companies to bring products to market faster and with fewer errors. Insert molding, another critical service, involves placing a pre-formed component into a mold and then injecting plastic around it. This technique is often used to enhance the strength and functionality of a product by integrating metal or other materials into the plastic part. High-temperature molding is essential for industries that require parts to withstand extreme conditions, such as automotive and aerospace. This process uses specialized materials that can endure high temperatures without degrading, ensuring the durability and reliability of the final product. Thin-wall molding focuses on creating lightweight parts with reduced material usage, which is particularly important in industries like consumer electronics where space and weight are at a premium. Multi-cavity molding is a technique that allows for the production of multiple parts in a single molding cycle, significantly increasing efficiency and reducing costs. This method is ideal for high-volume production runs where consistency and speed are crucial. Other services within the market include overmolding, which involves molding a layer of material over an existing part to improve its appearance or functionality, and micro-molding, which is used to produce extremely small and precise components for industries like medical and electronics. Each of these services addresses specific needs within the market, and companies often offer a combination of these techniques to meet the diverse requirements of their clients. As the demand for more complex and precise components grows, the Global Prototype Injection Molding Service Market continues to evolve, incorporating new technologies and materials to meet the challenges of modern manufacturing.

Automotive, Aerospace, Medical and Healthcare, Consumer Goods, Electronics, Others in the Global Prototype Injection Molding Service Market:

The Global Prototype Injection Molding Service Market finds extensive application across various industries, each with its unique set of requirements and challenges. In the automotive sector, prototype injection molding is used to develop and test components such as dashboards, bumpers, and engine parts. The ability to quickly produce and evaluate prototypes allows automotive manufacturers to innovate and improve vehicle performance and safety. In the aerospace industry, the demand for lightweight and durable components is critical. Prototype injection molding enables the production of complex parts that meet stringent safety and performance standards, facilitating advancements in aircraft design and efficiency. The medical and healthcare industry relies on prototype injection molding to develop medical devices and components that require high precision and biocompatibility. This service is crucial for creating prototypes of surgical instruments, diagnostic equipment, and prosthetics, ensuring that they meet regulatory standards and function as intended. In the consumer goods sector, prototype injection molding is used to create a wide range of products, from household appliances to personal care items. The ability to rapidly prototype and test designs allows companies to respond quickly to market trends and consumer preferences. The electronics industry benefits from prototype injection molding by producing components such as casings, connectors, and circuit boards. The precision and efficiency of this service are essential for developing products that are both functional and aesthetically pleasing. Other industries, such as packaging and construction, also utilize prototype injection molding to create innovative solutions that meet specific needs. Overall, the Global Prototype Injection Molding Service Market plays a vital role in enabling industries to innovate and bring new products to market efficiently and cost-effectively.

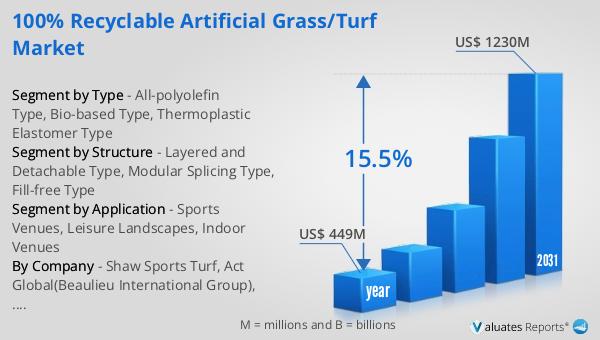

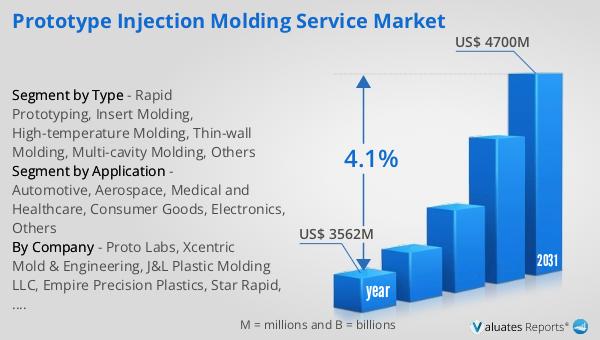

Global Prototype Injection Molding Service Market Outlook:

In 2024, the global market for Prototype Injection Molding Service was valued at approximately $3,562 million. This market is projected to grow steadily, reaching an estimated size of $4,700 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.1% over the forecast period. The steady increase in market size reflects the growing demand for efficient and cost-effective prototyping solutions across various industries. As companies strive to reduce time-to-market and improve product quality, the need for advanced prototyping services continues to rise. The market's expansion is driven by technological advancements, increasing adoption of automation, and the growing emphasis on sustainability and material efficiency. Service providers in this market are continually innovating to offer more precise, reliable, and environmentally friendly solutions. The global nature of this market means that companies must also consider regional variations in demand, regulatory requirements, and customer preferences. As the market evolves, businesses that can adapt to these changes and offer comprehensive, tailored services are likely to thrive. The projected growth of the Global Prototype Injection Molding Service Market underscores its importance in modern manufacturing, providing essential support for product development and innovation across a wide range of industries.

| Report Metric | Details |

| Report Name | Prototype Injection Molding Service Market |

| Accounted market size in year | US$ 3562 million |

| Forecasted market size in 2031 | US$ 4700 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Proto Labs, Xcentric Mold & Engineering, J&L Plastic Molding LLC, Empire Precision Plastics, Star Rapid, PTI Engineered Plastics Inc., Aline Components, Elite Mold & Engineering Inc., Fathom, EVCO Plastics, Xometry, ICOMold, Deluxe Plastics, Jabil, HLH Rapid, Protoshop, Fast Radius, Quickparts, Stratasys, BTL Plastics, Kintec, APT Mold Manufacturing, PCBWay, MSI Mold, MPP Corp., Abtec Inc., Rapid Molding, Advanced Prototype Molding, Fortify, Weller PCB |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |