What is Global Mechanical Vacuum Pumps Market?

The Global Mechanical Vacuum Pumps Market is a dynamic and essential segment of the industrial equipment landscape, playing a crucial role in various applications across multiple industries. These pumps are designed to remove gas molecules from a sealed volume, creating a partial vacuum. This process is vital in numerous industrial processes where maintaining a controlled environment is necessary. The market for mechanical vacuum pumps is driven by the increasing demand for efficient and reliable vacuum systems in industries such as semiconductor manufacturing, chemical processing, and industrial manufacturing. As industries continue to evolve and require more sophisticated technologies, the demand for advanced vacuum pumps is expected to grow. The market is characterized by a diverse range of products, each tailored to specific applications and performance requirements. Manufacturers are continually innovating to improve the efficiency, reliability, and environmental impact of their products, ensuring they meet the ever-changing needs of their customers. The global reach of this market means that it is influenced by a variety of factors, including technological advancements, regulatory changes, and economic conditions, making it a complex and dynamic field.

Scroll Pump, Roots Pump, Screw Pump, Claw Type Pump, Rotary Vane Pump, Others in the Global Mechanical Vacuum Pumps Market:

Scroll pumps, roots pumps, screw pumps, claw type pumps, rotary vane pumps, and others are integral components of the Global Mechanical Vacuum Pumps Market, each offering unique advantages and applications. Scroll pumps are known for their quiet operation and high efficiency, making them ideal for applications where noise reduction is crucial. They work by using two interleaved spiral-shaped scrolls to compress and move gases, providing a smooth and continuous flow. Roots pumps, on the other hand, are renowned for their high pumping speeds and are often used in applications requiring rapid evacuation of large volumes. They operate by using two lobed rotors that rotate in opposite directions, creating a vacuum as they move. Screw pumps are versatile and can handle a wide range of gases and vapors, making them suitable for various industrial applications. They use two screw-shaped rotors that rotate in opposite directions to move gases through the pump. Claw type pumps are known for their dry operation, meaning they do not require any lubricants or sealing fluids, making them ideal for applications where contamination must be avoided. They operate by using two claw-shaped rotors that rotate in opposite directions, creating a vacuum as they move. Rotary vane pumps are widely used due to their simplicity and reliability. They consist of a rotor with vanes that slide in and out, trapping and compressing gases as the rotor turns. Each of these pump types has its own set of advantages and limitations, making them suitable for different applications and industries. Manufacturers continue to innovate and improve these technologies to meet the evolving needs of their customers, ensuring that they remain competitive in the global market.

Industrial & Manufacturing, Chemical Processing, Semiconductor & Electronics, Others in the Global Mechanical Vacuum Pumps Market:

The Global Mechanical Vacuum Pumps Market finds extensive usage across various sectors, including industrial and manufacturing, chemical processing, semiconductor and electronics, and others. In the industrial and manufacturing sector, vacuum pumps are essential for processes such as material handling, packaging, and drying. They help create the necessary vacuum conditions for these processes, ensuring efficiency and quality. In chemical processing, vacuum pumps are used to remove gases and vapors from chemical reactions, preventing contamination and ensuring the purity of the final product. They are also used in distillation and evaporation processes, where maintaining a controlled environment is crucial. The semiconductor and electronics industry relies heavily on vacuum pumps for processes such as wafer fabrication, coating, and etching. These processes require precise control of the environment to ensure the quality and performance of the final products. Vacuum pumps are also used in the production of flat panel displays and solar cells, where maintaining a vacuum is essential for the deposition of thin films. Other industries that utilize vacuum pumps include food and beverage, pharmaceuticals, and healthcare. In the food and beverage industry, vacuum pumps are used for packaging and preservation, ensuring the freshness and quality of the products. In pharmaceuticals, they are used in processes such as freeze-drying and vacuum distillation, where maintaining a controlled environment is crucial for the quality and efficacy of the final product. In healthcare, vacuum pumps are used in medical devices and equipment, such as suction machines and vacuum-assisted wound closure systems. The versatility and reliability of mechanical vacuum pumps make them indispensable in these industries, driving their demand and growth in the global market.

Global Mechanical Vacuum Pumps Market Outlook:

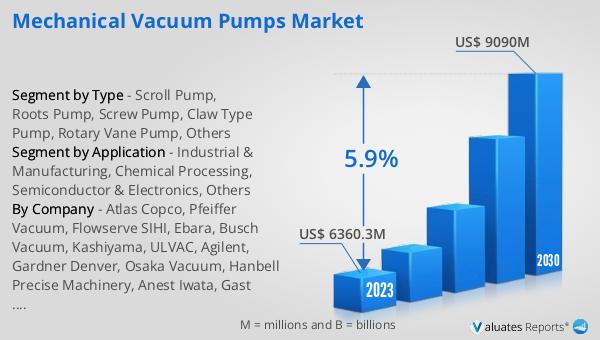

In 2024, the global market for Mechanical Vacuum Pumps was valued at approximately $6,787 million, and it is anticipated to expand to a revised size of around $10,080 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 34%. Among the various product types, scroll pumps emerge as the largest segment, capturing over 34% of the market share. This dominance is attributed to their efficiency and quiet operation, making them a preferred choice in many applications. In terms of application, the semiconductor and electronics sector is the largest, accounting for over 33% of the market share. This sector's reliance on vacuum pumps for critical processes such as wafer fabrication and thin-film deposition underscores the importance of these devices in maintaining the quality and performance of electronic components. The growth of the mechanical vacuum pumps market is driven by the increasing demand for advanced technologies and the need for efficient and reliable vacuum systems across various industries. As manufacturers continue to innovate and improve their products, the market is expected to witness sustained growth, offering numerous opportunities for stakeholders.

| Report Metric | Details |

| Report Name | Mechanical Vacuum Pumps Market |

| Accounted market size in year | US$ 6787 million |

| Forecasted market size in 2031 | US$ 10080 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco, Pfeiffer Vacuum, Flowserve SIHI, Ebara, Busch Vacuum, Kashiyama, ULVAC, Agilent, Gardner Denver, Osaka Vacuum, Hanbell Precise Machinery, Anest Iwata, Gast (IDEX), Labconco, Air Squared Inc, SKY Technology Development, Samson Pump, Becker Pumps, Graham, Shanghai Second Vacuum Pump Factory, Shandong Zhangqiu Blower, PPI Pumps, Xiamen East Asia |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |