What is Global Heat Resistant Polymethyl Methacrylate Market?

The Global Heat Resistant Polymethyl Methacrylate (PMMA) Market is a specialized segment within the broader plastics industry, focusing on a type of acrylic polymer known for its exceptional heat resistance. This material is a variant of standard PMMA, engineered to withstand higher temperatures without losing its structural integrity or clarity. Its unique properties make it an ideal choice for applications requiring durability and transparency under thermal stress. The market for this material is driven by its increasing use in industries such as automotive, electronics, and construction, where components are often exposed to high temperatures. The demand is further fueled by the growing trend towards lightweight and durable materials that can replace glass and metal in various applications. As industries continue to innovate and seek materials that offer both performance and cost-effectiveness, the Global Heat Resistant PMMA Market is poised for steady growth. This market is characterized by a competitive landscape with several key players investing in research and development to enhance the material's properties and expand its application scope. The ongoing advancements in polymer technology are expected to open new avenues for this versatile material, making it a critical component in modern manufacturing and design.

Extrusion Grade, Injection Grade in the Global Heat Resistant Polymethyl Methacrylate Market:

In the Global Heat Resistant Polymethyl Methacrylate Market, two primary grades are distinguished based on their processing methods: Extrusion Grade and Injection Grade. Extrusion Grade PMMA is specifically formulated for the extrusion process, where the material is melted and forced through a die to create continuous shapes like sheets, rods, and tubes. This grade is valued for its ability to produce large, uniform products with excellent surface finish and clarity. It is commonly used in applications where transparency and aesthetic appeal are crucial, such as in signage, displays, and lighting fixtures. The extrusion process allows for the production of complex profiles and shapes, making it a versatile choice for manufacturers looking to create custom designs. On the other hand, Injection Grade PMMA is tailored for the injection molding process, where the polymer is melted and injected into a mold to form intricate and detailed parts. This grade is known for its precision and ability to produce complex geometries with tight tolerances. It is widely used in the automotive and electronics industries, where components require high dimensional accuracy and strength. Injection Grade PMMA is also favored for its rapid production cycle, making it suitable for high-volume manufacturing. The choice between Extrusion and Injection Grade PMMA depends on the specific requirements of the application, including the desired shape, size, and production volume. Both grades offer excellent heat resistance, optical clarity, and weatherability, making them suitable for a wide range of applications. As the demand for lightweight and durable materials continues to rise, these two grades of Heat Resistant PMMA are expected to play a significant role in various industries. Manufacturers are continually exploring new formulations and processing techniques to enhance the performance of these materials and meet the evolving needs of the market. The ongoing research and development efforts in this field are likely to result in improved properties and expanded applications for both Extrusion and Injection Grade PMMA. As industries strive for greater efficiency and sustainability, the versatility and performance of Heat Resistant PMMA make it an attractive choice for modern manufacturing.

Transportation Industry, Optoelectronics Industry, Others in the Global Heat Resistant Polymethyl Methacrylate Market:

The usage of Global Heat Resistant Polymethyl Methacrylate (PMMA) spans several key industries, each benefiting from its unique properties. In the Transportation Industry, Heat Resistant PMMA is increasingly used for its lightweight and durable characteristics. It is commonly found in automotive components such as headlight lenses, interior panels, and exterior trims. The material's ability to withstand high temperatures without deforming makes it ideal for parts exposed to engine heat or direct sunlight. Additionally, its optical clarity and scratch resistance enhance the aesthetic appeal and longevity of vehicle components. In the Optoelectronics Industry, Heat Resistant PMMA is valued for its excellent light transmission and thermal stability. It is used in the production of optical lenses, light guides, and display panels, where clarity and precision are paramount. The material's resistance to yellowing and degradation under UV exposure ensures the longevity and performance of optoelectronic devices. Furthermore, its lightweight nature contributes to the development of portable and energy-efficient electronic products. Beyond these industries, Heat Resistant PMMA finds applications in various other sectors, including construction, healthcare, and consumer goods. In construction, it is used for glazing, skylights, and architectural features that require transparency and weather resistance. In healthcare, the material is employed in medical devices and equipment that demand sterilization and durability. Its biocompatibility and ease of fabrication make it suitable for a range of medical applications. In consumer goods, Heat Resistant PMMA is used in products such as eyewear, kitchenware, and home appliances, where aesthetics and performance are important. The versatility and adaptability of Heat Resistant PMMA make it a valuable material across diverse applications. As industries continue to innovate and seek materials that offer both performance and sustainability, the demand for Heat Resistant PMMA is expected to grow. Its ability to combine transparency, durability, and heat resistance makes it an attractive choice for manufacturers looking to enhance the functionality and appeal of their products. The ongoing advancements in polymer technology are likely to further expand the application scope of Heat Resistant PMMA, solidifying its position as a key material in modern manufacturing.

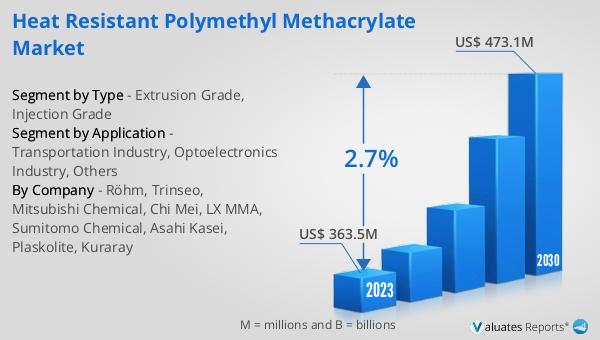

Global Heat Resistant Polymethyl Methacrylate Market Outlook:

The global market for Heat Resistant Polymethyl Methacrylate (PMMA) was valued at approximately $413 million in 2024, with projections indicating a growth to around $496 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.7% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold over 70% of the market share. Among the different product types, the Injection Grade segment emerges as the largest, accounting for more than 74% of the market. This dominance is attributed to the widespread use of Injection Grade PMMA in industries that require high precision and complex geometries, such as automotive and electronics. The material's ability to withstand high temperatures while maintaining clarity and strength makes it a preferred choice for manufacturers. As the demand for lightweight and durable materials continues to rise, the market for Heat Resistant PMMA is expected to experience steady growth. The ongoing advancements in polymer technology and the increasing focus on sustainability are likely to drive further innovation and expansion in this market. The competitive landscape is characterized by continuous research and development efforts aimed at enhancing the properties and applications of Heat Resistant PMMA. As industries seek materials that offer both performance and cost-effectiveness, the Global Heat Resistant PMMA Market is poised for continued growth and development.

| Report Metric | Details |

| Report Name | Heat Resistant Polymethyl Methacrylate Market |

| Accounted market size in year | US$ 413 million |

| Forecasted market size in 2031 | US$ 496 million |

| CAGR | 2.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Röhm, Trinseo, Mitsubishi Chemical, Chi Mei, LX MMA, Sumitomo Chemical, Asahi Kasei, Plaskolite, Kuraray |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |