What is Global Chip Epoxy Flux Market?

The Global Chip Epoxy Flux Market is a specialized segment within the electronics industry that focuses on the production and application of epoxy fluxes used in chip manufacturing. Epoxy fluxes are crucial in the assembly of semiconductor devices, serving as adhesives that facilitate the bonding of chips to substrates. These materials are essential for ensuring the reliability and performance of electronic components, as they help in the removal of oxides from metal surfaces, enhance solderability, and provide mechanical support. The market is driven by the increasing demand for electronic devices, advancements in semiconductor technology, and the need for high-performance materials in chip assembly. As the electronics industry continues to evolve, the Global Chip Epoxy Flux Market is expected to grow, driven by innovations in material science and the expanding applications of semiconductors in various sectors such as automotive, consumer electronics, and industrial equipment. The market is characterized by a competitive landscape with several key players investing in research and development to enhance product performance and meet the stringent requirements of modern electronic manufacturing.

Chip Epoxy Flux Without Filler Type, Chip Epoxy Flux With Filler Type in the Global Chip Epoxy Flux Market:

Chip Epoxy Flux Without Filler Type and Chip Epoxy Flux With Filler Type are two primary categories within the Global Chip Epoxy Flux Market, each serving distinct purposes in the semiconductor manufacturing process. Chip Epoxy Flux Without Filler Type is typically used in applications where a smooth, uniform coating is required without the addition of particulate fillers. This type of epoxy flux is favored for its ability to provide excellent adhesion and electrical insulation properties while maintaining a low viscosity, which is essential for precise application in delicate electronic components. It is particularly useful in scenarios where the minimization of thermal expansion and contraction is critical, as the absence of fillers reduces the potential for stress and cracking during thermal cycling. On the other hand, Chip Epoxy Flux With Filler Type incorporates various fillers to enhance specific properties such as thermal conductivity, mechanical strength, and dimensional stability. The inclusion of fillers allows this type of epoxy flux to better manage heat dissipation, which is crucial in high-power applications where thermal management is a significant concern. The fillers can also improve the mechanical robustness of the epoxy, making it suitable for use in environments subject to mechanical stress or vibration. This type of epoxy flux is often employed in applications where the electronic components are exposed to harsh conditions, as the fillers provide additional protection against environmental factors such as moisture and chemical exposure. Both types of chip epoxy fluxes play a vital role in the manufacturing of semiconductors, with their selection depending on the specific requirements of the application, such as the need for thermal management, mechanical strength, or electrical insulation. Manufacturers in the Global Chip Epoxy Flux Market continue to innovate and develop new formulations to meet the evolving demands of the electronics industry, ensuring that these materials remain integral to the production of reliable and high-performance semiconductor devices.

Automotive Chips, Consumer Electronics Chips, Industrial Equipment Chips, Others in the Global Chip Epoxy Flux Market:

The Global Chip Epoxy Flux Market finds extensive usage across various sectors, including automotive chips, consumer electronics chips, industrial equipment chips, and others, each with unique requirements and challenges. In the automotive industry, chip epoxy fluxes are crucial for the production of automotive chips that power a wide range of functions, from engine control units to advanced driver-assistance systems. The harsh operating conditions in automotive environments, such as extreme temperatures and vibrations, necessitate the use of robust epoxy fluxes that can provide reliable adhesion and protection for the chips. In consumer electronics, chip epoxy fluxes are used in the assembly of chips for devices such as smartphones, tablets, and laptops. The demand for miniaturization and high performance in consumer electronics drives the need for epoxy fluxes that offer excellent electrical insulation and thermal management properties, ensuring the reliability and longevity of the devices. In the industrial equipment sector, chip epoxy fluxes are used in the production of chips for machinery and equipment that operate in demanding environments. These applications require epoxy fluxes that can withstand mechanical stress, chemical exposure, and temperature fluctuations, providing reliable performance and protection for the chips. Other applications of chip epoxy fluxes include telecommunications, aerospace, and medical devices, where the need for high-performance materials is critical to ensure the functionality and reliability of the electronic components. The versatility and adaptability of chip epoxy fluxes make them indispensable in the manufacturing of semiconductor devices across various industries, with manufacturers continually developing new formulations to meet the specific needs of each application.

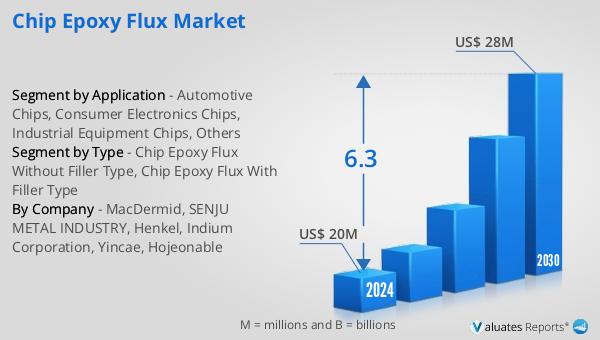

Global Chip Epoxy Flux Market Outlook:

The global market for Chip Epoxy Flux was valued at approximately $20.6 million in 2024, and it is anticipated to grow to a revised size of around $31.3 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% over the forecast period. This growth trajectory underscores the increasing demand for chip epoxy fluxes in the semiconductor industry, driven by advancements in technology and the expanding applications of electronic devices. The market is dominated by a few key players, with the top six manufacturers accounting for nearly 90% of the market share. These leading companies include MacDermid, SENJU METAL INDUSTRY, Henkel, Indium Corporation, Yincae, and Hojeonable, among others. Their dominance is attributed to their extensive product portfolios, strong research and development capabilities, and strategic partnerships with major semiconductor manufacturers. These companies are at the forefront of innovation, continually developing new formulations and technologies to meet the evolving needs of the electronics industry. As the demand for high-performance and reliable semiconductor devices continues to grow, the Global Chip Epoxy Flux Market is poised for significant expansion, with key players investing in research and development to enhance product performance and maintain their competitive edge in the market.

| Report Metric | Details |

| Report Name | Chip Epoxy Flux Market |

| Accounted market size in year | US$ 20.6 million |

| Forecasted market size in 2031 | US$ 31.3 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid, SENJU METAL INDUSTRY, Henkel, Indium Corporation, Yincae, Hojeonable, Hongfuxiang Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |