What is Global Automotive Airbag Connector Market?

The Global Automotive Airbag Connector Market is a specialized segment within the automotive industry that focuses on the production and distribution of connectors used in airbag systems. These connectors are crucial components that ensure the reliable deployment of airbags during a collision, thereby enhancing passenger safety. The market encompasses a variety of connector types, including wire-to-wire, wire-to-board, and board-to-board connectors, each serving specific functions within the airbag system. The demand for these connectors is driven by the increasing emphasis on vehicle safety standards and the growing adoption of advanced safety features in automobiles. As automotive manufacturers continue to innovate and integrate more sophisticated safety systems, the need for reliable and efficient airbag connectors is expected to rise. This market is characterized by technological advancements, regulatory compliance, and a competitive landscape with numerous players striving to offer high-quality and cost-effective solutions. The global reach of this market is evident as it caters to both passenger cars and commercial vehicles, reflecting its integral role in the broader automotive safety ecosystem.

Wire-to-Wire Connector, Wire to Board Connector, Board-to-Board Connector in the Global Automotive Airbag Connector Market:

Wire-to-wire connectors, wire-to-board connectors, and board-to-board connectors are integral components of the Global Automotive Airbag Connector Market, each serving distinct roles in the functionality and reliability of airbag systems. Wire-to-wire connectors are designed to connect two separate wires, ensuring a secure and stable electrical connection. These connectors are crucial in airbag systems as they facilitate the transmission of signals between different components, such as sensors and control units, which are essential for the timely deployment of airbags. The design of wire-to-wire connectors focuses on durability and resistance to environmental factors like vibration, temperature fluctuations, and moisture, which are common in automotive environments. On the other hand, wire-to-board connectors serve as the interface between wires and printed circuit boards (PCBs). These connectors are vital in airbag systems as they connect the wiring harness to the electronic control unit (ECU), which processes signals from various sensors to determine when to deploy the airbags. The reliability of wire-to-board connectors is paramount, as any failure could result in the malfunction of the airbag system. Manufacturers of these connectors prioritize precision engineering and robust materials to ensure consistent performance under challenging conditions. Board-to-board connectors, meanwhile, are used to connect two PCBs within the airbag system. These connectors are essential for maintaining the integrity of the electronic circuitry that controls airbag deployment. The design of board-to-board connectors emphasizes compactness and efficiency, as space within automotive systems is often limited. These connectors must also withstand the rigors of automotive environments, including mechanical stress and thermal cycling. The development of board-to-board connectors involves advanced engineering techniques to achieve high-density connections without compromising on reliability. In the context of the Global Automotive Airbag Connector Market, these three types of connectors collectively contribute to the overall safety and effectiveness of airbag systems. As automotive technology continues to evolve, the demand for innovative and reliable connector solutions is expected to grow, driving further advancements in connector design and manufacturing processes.

Passenger cars, Commercial Vehicle in the Global Automotive Airbag Connector Market:

The usage of Global Automotive Airbag Connector Market components in passenger cars and commercial vehicles highlights the critical role these connectors play in ensuring occupant safety across different vehicle types. In passenger cars, airbag connectors are integral to the deployment of airbags, which are a standard safety feature in modern vehicles. These connectors facilitate the communication between the airbag control unit and various sensors distributed throughout the vehicle. In the event of a collision, these sensors detect the impact and send signals to the control unit, which then triggers the deployment of the airbags. The reliability of airbag connectors in passenger cars is crucial, as any failure could compromise the safety of the vehicle's occupants. Manufacturers of passenger cars prioritize the integration of high-quality connectors to meet stringent safety standards and enhance the overall safety profile of their vehicles. In commercial vehicles, the role of airbag connectors is equally important, albeit with some differences in application. Commercial vehicles, such as trucks and buses, often operate under more demanding conditions and may be subject to higher levels of vibration and environmental stress. As a result, the connectors used in these vehicles must be designed to withstand such challenges while maintaining reliable performance. The deployment of airbags in commercial vehicles is critical for protecting drivers and passengers, particularly in high-impact collisions. The connectors used in these vehicles must ensure seamless communication between the airbag system components to facilitate timely deployment. The Global Automotive Airbag Connector Market caters to the specific needs of both passenger cars and commercial vehicles, offering a range of connector solutions that address the unique requirements of each vehicle type. As safety regulations continue to evolve and the demand for advanced safety features increases, the importance of reliable airbag connectors in both passenger and commercial vehicles is expected to grow, driving further innovation and development in this market segment.

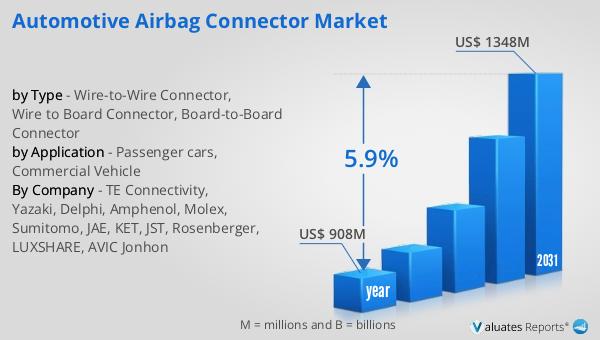

Global Automotive Airbag Connector Market Outlook:

The outlook for the Global Automotive Airbag Connector Market indicates a promising trajectory, with the market valued at approximately US$ 908 million in 2024. This valuation underscores the significant demand for airbag connectors, driven by the increasing emphasis on vehicle safety and the integration of advanced safety systems in modern automobiles. The market is projected to expand further, reaching an estimated size of US$ 1348 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.9% over the forecast period, highlighting the sustained demand for reliable and efficient airbag connectors. The projected growth is indicative of the ongoing advancements in automotive safety technology and the continuous efforts by manufacturers to enhance the safety features of their vehicles. As the automotive industry evolves, the role of airbag connectors becomes increasingly critical, necessitating the development of innovative solutions that meet the stringent safety standards and performance requirements of modern vehicles. The Global Automotive Airbag Connector Market is poised to play a pivotal role in the broader automotive safety landscape, contributing to the overall safety and reliability of vehicles worldwide.

| Report Metric | Details |

| Report Name | Automotive Airbag Connector Market |

| Accounted market size in year | US$ 908 million |

| Forecasted market size in 2031 | US$ 1348 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TE Connectivity, Yazaki, Delphi, Amphenol, Molex, Sumitomo, JAE, KET, JST, Rosenberger, LUXSHARE, AVIC Jonhon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |