What is Global Aircraft Fuel Solenoid Valve Market?

The Global Aircraft Fuel Solenoid Valve Market is a specialized segment within the broader aerospace industry, focusing on the production and distribution of solenoid valves used in aircraft fuel systems. These valves are critical components that control the flow of fuel to the aircraft's engines, ensuring efficient and safe operation. The market encompasses a range of solenoid valve types, including two-way, three-way, and other configurations, each designed to meet specific operational requirements. The demand for these valves is driven by the increasing production of commercial and military aircraft, as well as the need for advanced fuel management systems that enhance fuel efficiency and reduce emissions. Technological advancements in solenoid valve design, such as improved materials and electronic controls, are also contributing to market growth. Additionally, the market is influenced by regulatory standards and safety requirements that mandate the use of reliable and high-performance components in aircraft systems. As the aerospace industry continues to evolve, the Global Aircraft Fuel Solenoid Valve Market is expected to experience steady growth, driven by ongoing innovations and the expansion of the global aircraft fleet.

Two-way Solenoid Valve, Three-way Solenoid Valve, Others in the Global Aircraft Fuel Solenoid Valve Market:

In the Global Aircraft Fuel Solenoid Valve Market, different types of solenoid valves play crucial roles in managing fuel flow within aircraft systems. Two-way solenoid valves are among the most common types used in aircraft fuel systems. These valves have two ports and are designed to allow or block the flow of fuel. They are typically used in applications where a simple on/off control is required. The operation of a two-way solenoid valve is straightforward: when the solenoid coil is energized, the valve opens, allowing fuel to pass through; when the coil is de-energized, the valve closes, stopping the flow. This type of valve is valued for its simplicity, reliability, and quick response time, making it ideal for applications where precise control of fuel flow is essential. Three-way solenoid valves, on the other hand, have three ports and are used in more complex fuel management systems. These valves can direct the flow of fuel between different pathways, allowing for more sophisticated control of fuel distribution. In a typical three-way solenoid valve, one port is connected to the fuel source, while the other two ports can be connected to different parts of the fuel system. By energizing or de-energizing the solenoid coil, the valve can switch the flow of fuel between the two output ports. This capability makes three-way solenoid valves suitable for applications where fuel needs to be redirected or mixed, such as in fuel transfer systems or in systems that require the blending of different fuel types. In addition to two-way and three-way solenoid valves, the Global Aircraft Fuel Solenoid Valve Market also includes other specialized valve types designed for specific applications. These may include proportional solenoid valves, which allow for variable control of fuel flow, and pilot-operated solenoid valves, which use a smaller pilot valve to control a larger main valve. Proportional solenoid valves are particularly useful in applications where precise control of fuel flow is required, such as in fuel metering systems. Pilot-operated solenoid valves, on the other hand, are used in applications where high flow rates are needed, as they can handle larger volumes of fuel than direct-acting solenoid valves. The choice of solenoid valve type depends on various factors, including the specific requirements of the aircraft fuel system, the operating conditions, and the desired level of control. Each type of solenoid valve offers unique advantages and is suited to different applications within the aircraft fuel system. As the aerospace industry continues to advance, the demand for specialized solenoid valves is expected to grow, driven by the need for more efficient and reliable fuel management solutions. Manufacturers in the Global Aircraft Fuel Solenoid Valve Market are continually innovating to develop new valve designs that meet the evolving needs of the industry, ensuring that aircraft fuel systems remain safe, efficient, and compliant with regulatory standards.

Commercial Aircraft, Military Aircraft in the Global Aircraft Fuel Solenoid Valve Market:

The Global Aircraft Fuel Solenoid Valve Market plays a vital role in both commercial and military aviation, providing essential components that ensure the safe and efficient operation of aircraft fuel systems. In commercial aircraft, solenoid valves are used to control the flow of fuel from the tanks to the engines, as well as to manage fuel transfer between tanks. This is crucial for maintaining the balance and stability of the aircraft during flight. The use of solenoid valves in commercial aviation is driven by the need for reliable and efficient fuel management systems that can handle the demands of long-haul flights and high passenger volumes. As airlines continue to expand their fleets and increase the frequency of flights, the demand for advanced solenoid valves is expected to grow. In military aircraft, the requirements for solenoid valves are even more stringent, given the demanding operational environments and the need for rapid response times. Military aircraft often operate in extreme conditions, requiring solenoid valves that can withstand high temperatures, pressures, and vibrations. These valves are used in a variety of applications, including fuel transfer, engine control, and auxiliary power units. The ability to quickly and accurately control fuel flow is critical for military operations, where precision and reliability can mean the difference between mission success and failure. As a result, the Global Aircraft Fuel Solenoid Valve Market for military applications is characterized by a focus on high-performance, durable, and technologically advanced valve solutions. The use of solenoid valves in both commercial and military aircraft is also influenced by regulatory standards and safety requirements. Aviation authorities mandate the use of certified components that meet strict safety and performance criteria, ensuring that aircraft operate safely and efficiently. This has led to increased investment in research and development by manufacturers in the Global Aircraft Fuel Solenoid Valve Market, as they strive to develop innovative solutions that meet these stringent requirements. The ongoing advancements in solenoid valve technology, such as the development of lightweight materials and electronic controls, are helping to improve the performance and reliability of aircraft fuel systems, further driving the growth of the market. Overall, the Global Aircraft Fuel Solenoid Valve Market is a critical component of the aerospace industry, supporting the safe and efficient operation of both commercial and military aircraft. As the demand for air travel continues to rise and military operations become more complex, the need for advanced solenoid valve solutions is expected to increase. Manufacturers in the market are well-positioned to capitalize on these opportunities, leveraging their expertise and technological capabilities to deliver high-quality, reliable, and innovative products that meet the evolving needs of the aviation industry.

Global Aircraft Fuel Solenoid Valve Market Outlook:

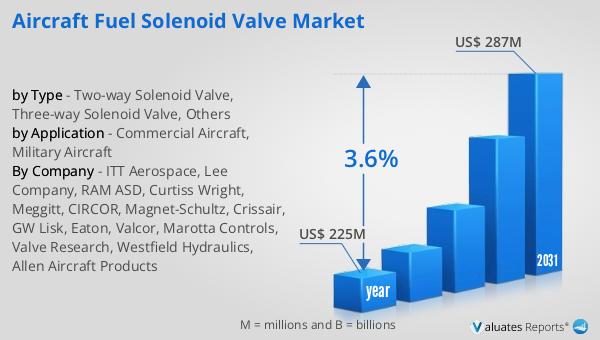

In 2024, the global market for Aircraft Fuel Solenoid Valves was valued at approximately $225 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $287 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.6% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for new aircraft, advancements in solenoid valve technology, and the ongoing need for efficient fuel management systems in the aviation industry. As airlines and military organizations continue to modernize their fleets and enhance their operational capabilities, the demand for high-performance solenoid valves is expected to grow. Additionally, the focus on reducing emissions and improving fuel efficiency is driving the adoption of advanced solenoid valve solutions that offer precise control and reliability. Manufacturers in the Global Aircraft Fuel Solenoid Valve Market are investing in research and development to create innovative products that meet the evolving needs of the industry, ensuring that they remain competitive in this dynamic market. As a result, the market is poised for continued growth, supported by the increasing complexity and sophistication of aircraft fuel systems.

| Report Metric | Details |

| Report Name | Aircraft Fuel Solenoid Valve Market |

| Accounted market size in year | US$ 225 million |

| Forecasted market size in 2031 | US$ 287 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITT Aerospace, Lee Company, RAM ASD, Curtiss Wright, Meggitt, CIRCOR, Magnet-Schultz, Crissair, GW Lisk, Eaton, Valcor, Marotta Controls, Valve Research, Westfield Hydraulics, Allen Aircraft Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |