What is Global Aircraft Fuel Solenoid Valve Market?

The Global Aircraft Fuel Solenoid Valve Market is a specialized segment within the broader aerospace industry, focusing on the production and distribution of solenoid valves used in aircraft fuel systems. These valves are critical components that control the flow of fuel to the aircraft's engines, ensuring efficient and safe operation. The market is driven by the increasing demand for commercial and military aircraft, as well as the need for advanced fuel management systems that enhance fuel efficiency and reduce emissions. Technological advancements in solenoid valve design, such as improved materials and miniaturization, are also contributing to market growth. Additionally, the market is influenced by stringent regulatory standards that require high-performance and reliable components in aircraft systems. As airlines and military organizations continue to upgrade their fleets with more fuel-efficient and environmentally friendly aircraft, the demand for advanced solenoid valves is expected to rise. The market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions that meet the evolving needs of the aerospace industry. Overall, the Global Aircraft Fuel Solenoid Valve Market plays a crucial role in supporting the aviation sector's growth and sustainability goals.

Two-way Solenoid Valve, Three-way Solenoid Valve, Others in the Global Aircraft Fuel Solenoid Valve Market:

In the Global Aircraft Fuel Solenoid Valve Market, different types of solenoid valves are used to manage the flow of fuel within an aircraft's fuel system. Two-way solenoid valves are among the most common types, designed to allow or block the flow of fuel through a single inlet and outlet. These valves are typically used in applications where a simple on-off control is required, making them ideal for basic fuel management tasks. They are known for their reliability and ease of maintenance, which are critical factors in the aviation industry where safety and efficiency are paramount. On the other hand, three-way solenoid valves offer more complex control options by providing an additional port. This allows them to direct the flow of fuel between two different paths, making them suitable for applications that require more sophisticated fuel routing and distribution. Three-way valves are often used in systems where fuel needs to be diverted or mixed, providing greater flexibility in fuel management. Other types of solenoid valves in the market include four-way and five-way valves, which offer even more control options for complex fuel systems. These valves are typically used in advanced aircraft models that require precise fuel management to optimize performance and reduce emissions. The choice of solenoid valve type depends on various factors, including the specific requirements of the aircraft's fuel system, the desired level of control, and the operating conditions. Manufacturers in the Global Aircraft Fuel Solenoid Valve Market are continually innovating to develop valves that offer improved performance, durability, and efficiency. This includes the use of advanced materials that can withstand extreme temperatures and pressures, as well as the integration of smart technologies that enable real-time monitoring and control of fuel flow. As the aviation industry continues to evolve, the demand for advanced solenoid valves is expected to grow, driven by the need for more efficient and environmentally friendly aircraft. Overall, the Global Aircraft Fuel Solenoid Valve Market is a dynamic and rapidly evolving sector that plays a critical role in supporting the aviation industry's growth and sustainability goals.

Commercial Aircraft, Military Aircraft in the Global Aircraft Fuel Solenoid Valve Market:

The usage of solenoid valves in the Global Aircraft Fuel Solenoid Valve Market is crucial for both commercial and military aircraft, serving as a key component in their fuel management systems. In commercial aircraft, solenoid valves are used to control the flow of fuel from the tanks to the engines, ensuring that the right amount of fuel is delivered at the right time. This is essential for optimizing fuel efficiency, reducing emissions, and ensuring the safe operation of the aircraft. As airlines strive to reduce their carbon footprint and operating costs, the demand for advanced solenoid valves that offer precise control and reliability is increasing. These valves are also used in auxiliary fuel systems, such as those that supply fuel to auxiliary power units (APUs) and other onboard systems. In military aircraft, solenoid valves play a critical role in ensuring the aircraft's operational readiness and performance. Military aircraft often operate in extreme conditions and require robust and reliable components that can withstand harsh environments. Solenoid valves used in military applications are designed to meet stringent military standards and are often equipped with advanced features such as redundancy and fail-safe mechanisms. These valves are used in various fuel systems, including those that supply fuel to the main engines, auxiliary systems, and weapons systems. The ability to precisely control fuel flow is essential for mission success, as it directly impacts the aircraft's range, speed, and maneuverability. In both commercial and military applications, the use of solenoid valves is driven by the need for efficient and reliable fuel management systems that enhance aircraft performance and safety. As the aviation industry continues to evolve, the demand for advanced solenoid valves is expected to grow, driven by the need for more efficient and environmentally friendly aircraft. Overall, the Global Aircraft Fuel Solenoid Valve Market plays a critical role in supporting the aviation industry's growth and sustainability goals, providing essential components that enable safe and efficient aircraft operation.

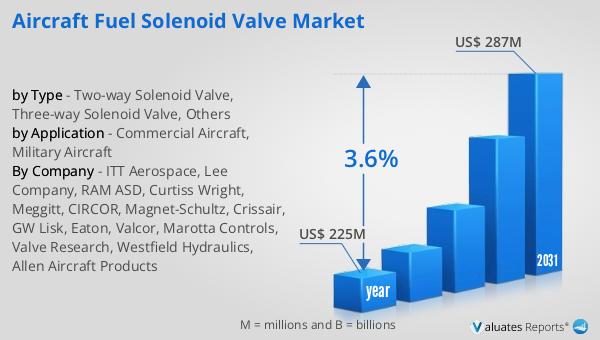

Global Aircraft Fuel Solenoid Valve Market Outlook:

The outlook for the Global Aircraft Fuel Solenoid Valve Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $225 million, and it is anticipated to expand to a revised size of $287 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.6% during the forecast period. This upward trend is driven by several factors, including the increasing demand for commercial and military aircraft, advancements in solenoid valve technology, and the need for more efficient and environmentally friendly fuel management systems. As airlines and military organizations continue to upgrade their fleets with more advanced aircraft, the demand for high-performance solenoid valves is expected to rise. Additionally, the market is influenced by stringent regulatory standards that require reliable and efficient components in aircraft systems. Manufacturers in the Global Aircraft Fuel Solenoid Valve Market are focusing on innovation and the development of new products that meet the evolving needs of the aerospace industry. This includes the use of advanced materials and smart technologies that enhance the performance and reliability of solenoid valves. Overall, the Global Aircraft Fuel Solenoid Valve Market is poised for steady growth, driven by the increasing demand for advanced fuel management solutions in the aviation industry.

| Report Metric | Details |

| Report Name | Aircraft Fuel Solenoid Valve Market |

| Accounted market size in year | US$ 225 million |

| Forecasted market size in 2031 | US$ 287 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITT Aerospace, Lee Company, RAM ASD, Curtiss Wright, Meggitt, CIRCOR, Magnet-Schultz, Crissair, GW Lisk, Eaton, Valcor, Marotta Controls, Valve Research, Westfield Hydraulics, Allen Aircraft Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |