What is Global Aircraft Fuel Solenoid Valve Market?

The Global Aircraft Fuel Solenoid Valve Market is a specialized segment within the aerospace industry that focuses on the production and distribution of solenoid valves used in aircraft fuel systems. These valves are critical components that control the flow of fuel to the engine, ensuring efficient and safe operation of the aircraft. Solenoid valves are electrically operated devices that use electromagnetic force to open or close the valve, allowing precise control over fuel flow. The market for these valves is driven by the increasing demand for commercial and military aircraft, advancements in aviation technology, and the need for more efficient fuel management systems. As airlines and military organizations seek to improve fuel efficiency and reduce emissions, the demand for advanced solenoid valves is expected to grow. Additionally, the market is influenced by regulatory standards and safety requirements, which necessitate the use of reliable and high-performance components in aircraft fuel systems. Manufacturers in this market are focused on developing innovative solutions that meet the evolving needs of the aerospace industry, including lightweight and durable materials, enhanced performance capabilities, and integration with advanced aircraft systems.

Two-way Solenoid Valve, Three-way Solenoid Valve, Others in the Global Aircraft Fuel Solenoid Valve Market:

In the Global Aircraft Fuel Solenoid Valve Market, different types of solenoid valves are utilized to meet the specific requirements of aircraft fuel systems. Two-way solenoid valves are among the most common types used in this market. These valves have two ports and are designed to allow or block the flow of fuel in a single direction. They are typically used in applications where simple on/off control is needed, such as in fuel shut-off systems. Two-way solenoid valves are valued for their simplicity, reliability, and ease of integration into existing fuel systems. They are often made from lightweight materials to reduce the overall weight of the aircraft, contributing to improved fuel efficiency. On the other hand, three-way solenoid valves have three ports and are used to direct the flow of fuel between two different paths. These valves are more complex than two-way valves and are used in applications where more precise control over fuel distribution is required. For example, they can be used to switch between different fuel tanks or to control the flow of fuel to different parts of the engine. Three-way solenoid valves are essential for optimizing fuel management in aircraft, ensuring that fuel is delivered efficiently and safely to where it is needed most. In addition to two-way and three-way solenoid valves, there are other types of solenoid valves used in the aircraft fuel solenoid valve market. These include four-way and five-way solenoid valves, which offer even greater control over fuel flow and distribution. These valves are used in more complex fuel systems where multiple flow paths need to be managed simultaneously. They are often used in conjunction with advanced control systems that monitor and adjust fuel flow in real-time, ensuring optimal performance and safety. The choice of solenoid valve type depends on various factors, including the specific requirements of the aircraft, the complexity of the fuel system, and the desired level of control over fuel flow. Manufacturers in the Global Aircraft Fuel Solenoid Valve Market are continually innovating to develop new valve designs that meet the evolving needs of the aerospace industry. This includes the use of advanced materials and manufacturing techniques to produce valves that are lighter, more durable, and capable of withstanding the harsh conditions of flight. Additionally, there is a growing focus on developing solenoid valves that are compatible with alternative fuels, such as biofuels and synthetic fuels, as the aviation industry seeks to reduce its environmental impact. Overall, the Global Aircraft Fuel Solenoid Valve Market is characterized by a diverse range of products that cater to the specific needs of different types of aircraft and fuel systems. Whether it's a simple two-way valve for basic fuel control or a complex multi-way valve for advanced fuel management, solenoid valves play a crucial role in ensuring the safe and efficient operation of aircraft.

Commercial Aircraft, Military Aircraft in the Global Aircraft Fuel Solenoid Valve Market:

The usage of solenoid valves in the Global Aircraft Fuel Solenoid Valve Market is critical for both commercial and military aircraft. In commercial aircraft, solenoid valves are used to manage the flow of fuel from the tanks to the engines, ensuring that the aircraft operates efficiently and safely. These valves are essential for maintaining the correct fuel pressure and flow rate, which is crucial for optimal engine performance. In addition to controlling fuel flow, solenoid valves are also used in fuel transfer systems, allowing fuel to be moved between different tanks to maintain balance and stability during flight. This is particularly important for long-haul flights, where fuel management is critical to ensure that the aircraft can reach its destination without running out of fuel. In military aircraft, solenoid valves play a similar role in managing fuel flow, but they are often subject to more demanding requirements due to the unique operational needs of military missions. Military aircraft may need to operate in extreme conditions, such as high altitudes, low temperatures, and high-speed maneuvers, which can place additional stress on the fuel system. Solenoid valves used in military aircraft are designed to withstand these conditions, providing reliable performance even in the most challenging environments. Additionally, military aircraft may require more complex fuel management systems to support a wider range of missions, including combat operations, reconnaissance, and transport. Solenoid valves are used to control the flow of fuel to different parts of the aircraft, ensuring that the engines receive the necessary fuel supply to perform their tasks. This includes managing fuel flow to auxiliary power units, which provide additional power for onboard systems and equipment. The use of solenoid valves in both commercial and military aircraft is driven by the need for reliable and efficient fuel management systems. As the aviation industry continues to evolve, there is a growing demand for solenoid valves that can meet the increasing performance and safety requirements of modern aircraft. This includes the development of valves that are compatible with new fuel types, such as biofuels and synthetic fuels, as well as the integration of advanced control systems that can monitor and adjust fuel flow in real-time. Overall, the Global Aircraft Fuel Solenoid Valve Market plays a vital role in ensuring the safe and efficient operation of both commercial and military aircraft. By providing precise control over fuel flow, solenoid valves help to optimize engine performance, reduce fuel consumption, and enhance the overall safety and reliability of the aircraft.

Global Aircraft Fuel Solenoid Valve Market Outlook:

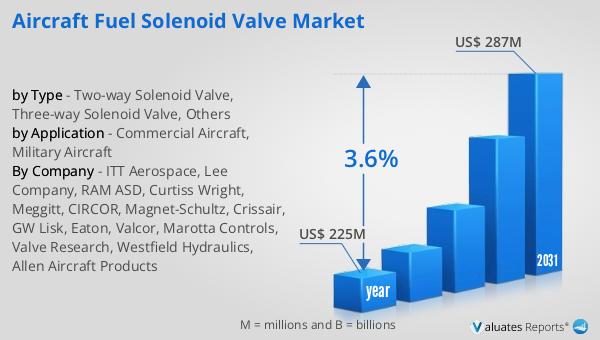

The global market for Aircraft Fuel Solenoid Valve was valued at $225 million in 2024 and is anticipated to grow to a revised size of $287 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth is indicative of the increasing demand for advanced fuel management systems in the aviation industry, driven by the need for improved fuel efficiency and reduced emissions. As airlines and military organizations continue to seek ways to optimize their operations and reduce costs, the demand for high-performance solenoid valves is expected to rise. The market is also influenced by regulatory standards and safety requirements, which necessitate the use of reliable and high-quality components in aircraft fuel systems. Manufacturers in this market are focused on developing innovative solutions that meet the evolving needs of the aerospace industry, including lightweight and durable materials, enhanced performance capabilities, and integration with advanced aircraft systems. As the aviation industry continues to evolve, the Global Aircraft Fuel Solenoid Valve Market is poised for continued growth, driven by the increasing demand for efficient and reliable fuel management solutions.

| Report Metric | Details |

| Report Name | Aircraft Fuel Solenoid Valve Market |

| Accounted market size in year | US$ 225 million |

| Forecasted market size in 2031 | US$ 287 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITT Aerospace, Lee Company, RAM ASD, Curtiss Wright, Meggitt, CIRCOR, Magnet-Schultz, Crissair, GW Lisk, Eaton, Valcor, Marotta Controls, Valve Research, Westfield Hydraulics, Allen Aircraft Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |