What is Global Aircraft Fuel Solenoid Valve Market?

The Global Aircraft Fuel Solenoid Valve Market is a specialized segment within the aerospace industry that focuses on the production and distribution of solenoid valves used in aircraft fuel systems. These valves play a crucial role in controlling the flow of fuel to the aircraft's engines, ensuring efficient and safe operation. Solenoid valves are electromechanically operated devices that use an electric current to generate a magnetic field, which in turn opens or closes the valve. This precise control is essential for maintaining optimal fuel flow, which directly impacts the performance and safety of the aircraft. The market for these valves is driven by the increasing demand for commercial and military aircraft, advancements in aerospace technology, and the need for more efficient fuel management systems. As airlines and military organizations seek to improve fuel efficiency and reduce emissions, the demand for advanced solenoid valves is expected to grow. The market is characterized by a mix of established players and new entrants, all striving to innovate and offer more reliable and efficient solutions. The global reach of this market means that manufacturers must adhere to stringent international standards and regulations, ensuring the highest levels of quality and safety.

Two-way Solenoid Valve, Three-way Solenoid Valve, Others in the Global Aircraft Fuel Solenoid Valve Market:

In the Global Aircraft Fuel Solenoid Valve Market, different types of solenoid valves are used, each serving specific functions within the aircraft's fuel system. Two-way solenoid valves are among the most common types used in aircraft. These valves have two ports: an inlet and an outlet. They are designed to allow or block the flow of fuel, acting as a simple on/off switch. When the solenoid is energized, the valve opens, allowing fuel to pass through; when de-energized, the valve closes, stopping the flow. This type of valve is typically used in applications where a straightforward control of fuel flow is required, such as in fuel supply lines or for isolating certain sections of the fuel system during maintenance or emergencies. Three-way solenoid valves, on the other hand, have three ports and are used to direct the flow of fuel between two different paths. These valves are more complex than two-way valves and are often used in applications where the fuel needs to be diverted from one path to another. For example, they can be used to switch between different fuel tanks or to control the flow of fuel to different engines. The ability to redirect fuel flow makes three-way valves particularly useful in aircraft with multiple engines or fuel tanks, where flexibility in fuel management is crucial. Other types of solenoid valves used in the aircraft fuel system include four-way and five-way valves, which offer even more complex flow control options. These valves are typically used in more advanced fuel management systems, where precise control over multiple flow paths is required. In addition to the basic function of controlling fuel flow, solenoid valves in aircraft are often equipped with additional features to enhance their performance and reliability. For example, many valves are designed to operate under extreme temperatures and pressures, ensuring they can function effectively in the harsh conditions of flight. Some valves also incorporate fail-safe mechanisms, which automatically close the valve in the event of a power failure, preventing uncontrolled fuel flow. The materials used in the construction of solenoid valves are also critical to their performance. Valves are typically made from high-strength metals such as stainless steel or titanium, which offer excellent resistance to corrosion and wear. The internal components of the valve, such as the seals and diaphragms, are often made from specialized materials that can withstand exposure to fuel and other chemicals. The design and manufacturing of solenoid valves for aircraft applications require a high level of precision and quality control. Manufacturers must adhere to strict industry standards and regulations, ensuring that each valve meets the necessary safety and performance requirements. This often involves rigorous testing and inspection processes, including pressure testing, leak testing, and functional testing. The global market for aircraft fuel solenoid valves is highly competitive, with numerous manufacturers vying for market share. Companies in this market must continually innovate and improve their products to meet the evolving needs of the aerospace industry. This includes developing valves with enhanced performance characteristics, such as faster response times, lower power consumption, and greater durability. As the demand for more fuel-efficient and environmentally friendly aircraft continues to grow, the role of solenoid valves in achieving these goals becomes increasingly important. By providing precise control over fuel flow, these valves help optimize engine performance, reduce fuel consumption, and minimize emissions. This not only benefits airlines and military organizations by lowering operating costs and improving sustainability but also contributes to the overall safety and reliability of air travel.

Commercial Aircraft, Military Aircraft in the Global Aircraft Fuel Solenoid Valve Market:

The usage of Global Aircraft Fuel Solenoid Valve Market in commercial and military aircraft is integral to the efficient and safe operation of these vehicles. In commercial aircraft, solenoid valves are used extensively throughout the fuel system to manage the flow of fuel from the tanks to the engines. These valves ensure that the correct amount of fuel is delivered to the engines at all times, optimizing performance and fuel efficiency. In addition to controlling the flow of fuel, solenoid valves are also used to isolate sections of the fuel system during maintenance or in the event of a malfunction. This allows for quick and easy repairs, minimizing downtime and ensuring that aircraft can return to service as soon as possible. In military aircraft, the requirements for solenoid valves are even more demanding. These aircraft often operate in extreme conditions and require highly reliable and durable components. Solenoid valves used in military applications must be able to withstand high temperatures, pressures, and vibrations, while still providing precise control over fuel flow. In addition to their use in the fuel system, solenoid valves are also used in other critical systems within military aircraft, such as hydraulic and pneumatic systems. The ability to quickly and accurately control the flow of fluids in these systems is essential for the performance and safety of the aircraft. The use of solenoid valves in both commercial and military aircraft is driven by the need for more efficient and reliable fuel management systems. As the aerospace industry continues to evolve, the demand for advanced solenoid valves is expected to grow. This is particularly true in the commercial sector, where airlines are under increasing pressure to reduce fuel consumption and emissions. By providing precise control over fuel flow, solenoid valves help optimize engine performance and reduce the environmental impact of air travel. In the military sector, the need for advanced solenoid valves is driven by the increasing complexity of modern aircraft. As these aircraft become more sophisticated, the demand for components that can provide precise control over critical systems is expected to grow. This includes not only fuel systems but also hydraulic and pneumatic systems, where solenoid valves play a crucial role. The global market for aircraft fuel solenoid valves is characterized by a mix of established players and new entrants, all striving to innovate and offer more reliable and efficient solutions. As the demand for more fuel-efficient and environmentally friendly aircraft continues to grow, the role of solenoid valves in achieving these goals becomes increasingly important. By providing precise control over fuel flow, these valves help optimize engine performance, reduce fuel consumption, and minimize emissions. This not only benefits airlines and military organizations by lowering operating costs and improving sustainability but also contributes to the overall safety and reliability of air travel.

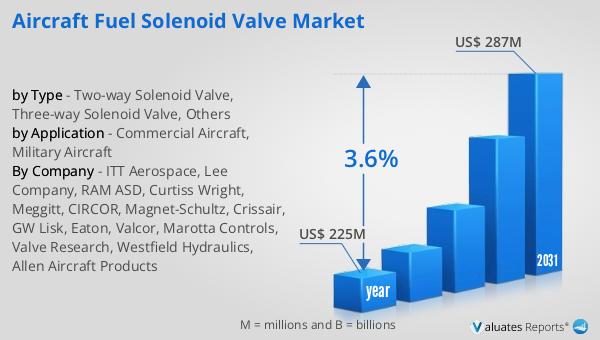

Global Aircraft Fuel Solenoid Valve Market Outlook:

The global market for Aircraft Fuel Solenoid Valve was valued at $225 million in 2024 and is anticipated to expand to a revised size of $287 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth trajectory underscores the increasing demand for solenoid valves in the aerospace industry, driven by the need for more efficient and reliable fuel management systems. As airlines and military organizations seek to improve fuel efficiency and reduce emissions, the demand for advanced solenoid valves is expected to grow. The market is characterized by a mix of established players and new entrants, all striving to innovate and offer more reliable and efficient solutions. The global reach of this market means that manufacturers must adhere to stringent international standards and regulations, ensuring the highest levels of quality and safety. The increasing complexity of modern aircraft, coupled with the need for more efficient and reliable fuel management systems, is expected to drive the demand for solenoid valves in the coming years. As the aerospace industry continues to evolve, the role of solenoid valves in achieving these goals becomes increasingly important. By providing precise control over fuel flow, these valves help optimize engine performance, reduce fuel consumption, and minimize emissions. This not only benefits airlines and military organizations by lowering operating costs and improving sustainability but also contributes to the overall safety and reliability of air travel.

| Report Metric | Details |

| Report Name | Aircraft Fuel Solenoid Valve Market |

| Accounted market size in year | US$ 225 million |

| Forecasted market size in 2031 | US$ 287 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITT Aerospace, Lee Company, RAM ASD, Curtiss Wright, Meggitt, CIRCOR, Magnet-Schultz, Crissair, GW Lisk, Eaton, Valcor, Marotta Controls, Valve Research, Westfield Hydraulics, Allen Aircraft Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |