What is Global Closed End Splice Market?

The Global Closed End Splice Market is a specialized segment within the electrical components industry, focusing on devices used to connect and terminate wires securely. These splices are essential in ensuring reliable electrical connections, preventing short circuits, and maintaining the integrity of electrical systems. Closed end splices are typically used in situations where a permanent connection is required, and they are designed to accommodate various wire gauges. The market for these splices is driven by the increasing demand for efficient and safe electrical connections across various industries, including automotive, electronics, and home appliances. As technology advances and industries continue to grow, the need for robust and reliable electrical connections becomes more critical, thereby fueling the demand for closed end splices. The market is characterized by a range of products that cater to different wire sizes and applications, ensuring that there is a suitable solution for every need. Manufacturers in this market are continually innovating to improve the performance and reliability of their products, which in turn drives market growth. The global closed end splice market is poised for significant expansion as industries increasingly prioritize safety and efficiency in their electrical systems.

Below10 AWG, 10-20 AWG, Above20 AWG in the Global Closed End Splice Market:

In the Global Closed End Splice Market, wire gauges play a crucial role in determining the appropriate splice for specific applications. Wire gauge refers to the diameter of the wire, and it is an essential factor in ensuring a secure and efficient electrical connection. The market is segmented into three main categories based on wire gauge: Below 10 AWG, 10-20 AWG, and Above 20 AWG. Each category serves different applications and industries, catering to specific needs and requirements. Below 10 AWG splices are typically used in heavy-duty applications where larger wire diameters are necessary to handle higher current loads. These splices are commonly found in industrial settings, power distribution systems, and large-scale electrical installations. The robust nature of these splices ensures that they can withstand the demands of high-power applications, providing reliable and durable connections. In contrast, the 10-20 AWG category is more versatile and widely used across various industries. This range of wire gauges is suitable for medium-duty applications, making it ideal for automotive electronics, home appliances, and consumer electronics. The flexibility of these splices allows them to be used in a wide range of applications, providing secure connections for both power and signal transmission. The Above 20 AWG category is typically used for lighter applications where smaller wire diameters are sufficient. These splices are often found in consumer electronics, telecommunications, and other low-power applications. The smaller size of these splices makes them ideal for compact and space-constrained environments, where efficient use of space is a priority. Each of these categories plays a vital role in the Global Closed End Splice Market, ensuring that there is a suitable solution for every application. Manufacturers in this market are continually developing new products to meet the evolving needs of their customers, focusing on improving the performance, reliability, and ease of use of their splices. As industries continue to advance and the demand for efficient electrical connections grows, the importance of selecting the right splice for the right application becomes increasingly critical. The Global Closed End Splice Market is well-positioned to meet these demands, providing a wide range of products that cater to the diverse needs of its customers.

Automotive Electronics, Home Appliances, Consumer Electronics, New Energy Industry, Automation Control Industry in the Global Closed End Splice Market:

The Global Closed End Splice Market finds extensive usage across various industries, each with its unique requirements and challenges. In the automotive electronics sector, closed end splices are crucial for ensuring reliable connections in complex wiring systems. Modern vehicles are equipped with numerous electronic components, from infotainment systems to advanced driver-assistance systems (ADAS), all of which require secure and efficient electrical connections. Closed end splices provide the necessary reliability and durability to withstand the harsh conditions often encountered in automotive environments, such as temperature fluctuations, vibrations, and exposure to moisture. In the home appliances industry, closed end splices are used to connect wires in devices such as refrigerators, washing machines, and air conditioners. These appliances require robust electrical connections to ensure safe and efficient operation, and closed end splices offer a reliable solution for achieving this. The consumer electronics industry also relies heavily on closed end splices for connecting wires in devices such as smartphones, tablets, and laptops. As these devices become increasingly compact and feature-rich, the need for efficient and space-saving electrical connections becomes more critical. Closed end splices provide a solution that meets these requirements, ensuring reliable performance in a compact form factor. The new energy industry, which includes renewable energy sources such as solar and wind power, also benefits from the use of closed end splices. These splices are used to connect wires in solar panels, wind turbines, and other renewable energy systems, ensuring efficient power transmission and minimizing energy loss. The reliability and durability of closed end splices make them an ideal choice for these applications, where long-term performance and minimal maintenance are essential. Finally, the automation control industry relies on closed end splices for connecting wires in control panels, sensors, and other automation equipment. These splices provide the necessary reliability and performance to ensure smooth and efficient operation of automated systems, which are often critical to the success of modern manufacturing and industrial processes. In summary, the Global Closed End Splice Market plays a vital role in supporting the electrical connection needs of various industries, providing reliable and efficient solutions that meet the unique challenges of each sector.

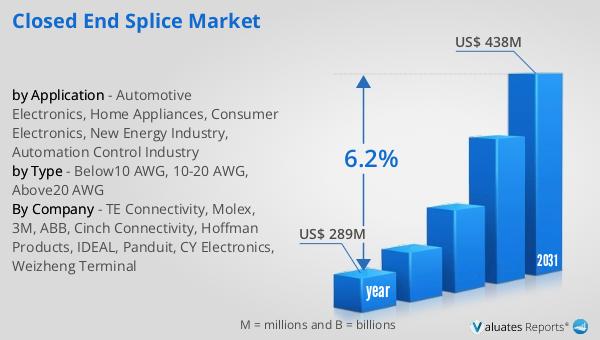

Global Closed End Splice Market Outlook:

The global market for Closed End Splice was valued at $289 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $438 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. This upward trajectory is indicative of the increasing demand for reliable and efficient electrical connections across various industries. As industries continue to evolve and expand, the need for robust and durable electrical components becomes more pronounced, driving the demand for closed end splices. The market's growth is further supported by technological advancements and innovations in splice design and materials, which enhance the performance and reliability of these products. Manufacturers are continually investing in research and development to create splices that meet the ever-changing needs of their customers, ensuring that they remain competitive in the global market. The projected growth of the Global Closed End Splice Market highlights the importance of these components in modern electrical systems and underscores the critical role they play in ensuring the safety and efficiency of electrical connections. As the market continues to expand, it presents numerous opportunities for manufacturers and suppliers to capitalize on the growing demand for high-quality closed end splices.

| Report Metric | Details |

| Report Name | Closed End Splice Market |

| Accounted market size in year | US$ 289 million |

| Forecasted market size in 2031 | US$ 438 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TE Connectivity, Molex, 3M, ABB, Cinch Connectivity, Hoffman Products, IDEAL, Panduit, CY Electronics, Weizheng Terminal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |