What is Global Parallel Splicing Market?

The Global Parallel Splicing Market is an essential segment within the broader electrical and electronics industry, focusing on the technology and processes involved in joining two or more electrical conductors. This market is crucial for ensuring efficient and reliable electrical connections, which are fundamental in various applications ranging from consumer electronics to industrial machinery. Parallel splicing involves the use of specialized connectors and techniques to merge conductors side by side, allowing for seamless electrical flow and minimizing resistance. This method is particularly valued for its ability to maintain the integrity of the electrical circuit while providing a durable and long-lasting connection. The market is driven by the increasing demand for advanced electrical systems in various sectors, including automotive, telecommunications, and renewable energy. As industries continue to evolve and require more sophisticated electrical solutions, the need for efficient splicing technologies like parallel splicing is expected to grow. This market is characterized by continuous innovation, with companies investing in research and development to enhance the performance and reliability of splicing products. Overall, the Global Parallel Splicing Market plays a pivotal role in supporting the infrastructure of modern electrical systems, ensuring safety, efficiency, and sustainability.

Below10 AWG, 10-20 AWG, Above20 AWG in the Global Parallel Splicing Market:

In the Global Parallel Splicing Market, the categorization based on wire gauge sizes such as Below 10 AWG, 10-20 AWG, and Above 20 AWG is significant for understanding the diverse applications and requirements of splicing technologies. AWG, or American Wire Gauge, is a standardized system used to denote the diameter of electrical conductors. Each category serves distinct purposes and is chosen based on the specific electrical and mechanical needs of an application. Below 10 AWG wires are typically thicker and used in applications requiring high current capacity and low resistance. These wires are often found in heavy-duty industrial equipment, power distribution systems, and large-scale renewable energy installations. The splicing of such wires demands robust connectors and techniques to ensure a secure and efficient connection, capable of handling substantial electrical loads without overheating or failure. The market for splicing solutions in this category is driven by the need for reliable and durable connections in high-power applications, where safety and performance are paramount. On the other hand, the 10-20 AWG category represents a more versatile range of wire sizes, commonly used in automotive, telecommunications, and consumer electronics. These wires balance current capacity and flexibility, making them suitable for a wide array of applications. In the automotive industry, for instance, 10-20 AWG wires are used in wiring harnesses, connecting various electrical components within a vehicle. The splicing solutions for this category focus on providing compact, efficient, and easy-to-install connectors that can withstand the demanding conditions of automotive environments, such as vibration, temperature fluctuations, and exposure to moisture. Similarly, in telecommunications, these wires are used in networking equipment and infrastructure, where reliable connections are crucial for maintaining signal integrity and performance. The splicing market for 10-20 AWG wires is characterized by innovation in connector design, aiming to enhance ease of use, reliability, and cost-effectiveness. Above 20 AWG wires are thinner and used in applications where space constraints and flexibility are critical. These wires are prevalent in consumer electronics, where compact and lightweight designs are essential. The splicing solutions for this category prioritize miniaturization and ease of integration, allowing for seamless incorporation into small electronic devices. In addition, these wires are used in precision equipment and instrumentation, where accurate and reliable connections are vital for performance. The market for splicing solutions in this category is driven by the demand for high-quality, reliable connections that can be easily integrated into compact and complex electronic systems. Overall, the Global Parallel Splicing Market's segmentation based on AWG sizes highlights the diverse needs and applications of splicing technologies, with each category offering unique challenges and opportunities for innovation and growth.

Automotive Electronics, Home Appliances, Consumer Electronics, New Energy Industry, Automation Control Industry in the Global Parallel Splicing Market:

The Global Parallel Splicing Market finds extensive usage across various industries, including automotive electronics, home appliances, consumer electronics, the new energy industry, and the automation control industry. In automotive electronics, parallel splicing is crucial for creating reliable connections within the complex wiring systems of modern vehicles. As vehicles become more technologically advanced, with features such as advanced driver-assistance systems (ADAS), infotainment systems, and electric drivetrains, the demand for efficient and durable splicing solutions increases. Parallel splicing ensures that electrical connections within the vehicle are secure and capable of handling the increased electrical loads associated with these advanced systems. In home appliances, parallel splicing is used to connect various electrical components, ensuring the safe and efficient operation of devices such as refrigerators, washing machines, and air conditioners. The reliability of these connections is vital for the performance and longevity of the appliances, as well as for ensuring user safety. In consumer electronics, parallel splicing is essential for creating compact and efficient connections within devices such as smartphones, tablets, and laptops. As these devices continue to evolve, with increasing functionality and performance demands, the need for advanced splicing solutions that can accommodate the miniaturization and complexity of modern electronics grows. In the new energy industry, parallel splicing plays a critical role in the installation and maintenance of renewable energy systems, such as solar panels and wind turbines. These systems require robust and reliable electrical connections to ensure efficient energy transfer and minimize losses. Parallel splicing solutions are designed to withstand the harsh environmental conditions often encountered in renewable energy installations, such as extreme temperatures, moisture, and UV exposure. In the automation control industry, parallel splicing is used to connect various sensors, actuators, and control systems, enabling the seamless operation of automated processes. The reliability and efficiency of these connections are crucial for maintaining the performance and safety of automated systems, which are increasingly used in manufacturing, logistics, and other industrial applications. Overall, the Global Parallel Splicing Market plays a vital role in supporting the infrastructure of these diverse industries, providing the necessary technology and solutions to ensure efficient, reliable, and safe electrical connections.

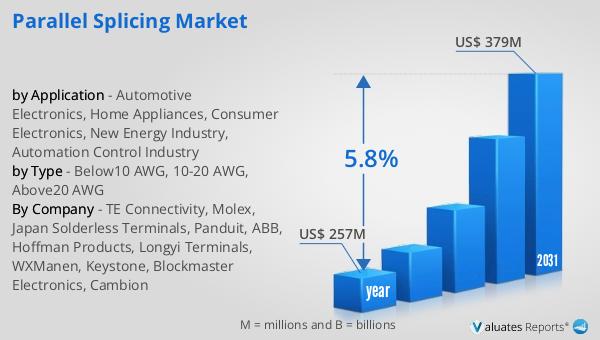

Global Parallel Splicing Market Outlook:

The global market for Parallel Splicing, valued at US$ 257 million in 2024, is anticipated to expand significantly, reaching an estimated size of US$ 379 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.8% over the forecast period. This upward trend is indicative of the increasing demand for advanced splicing solutions across various industries, driven by the need for efficient and reliable electrical connections. The market's expansion is fueled by the continuous advancements in technology and the growing adoption of sophisticated electrical systems in sectors such as automotive, telecommunications, and renewable energy. As industries evolve and require more complex and efficient electrical solutions, the demand for parallel splicing technologies is expected to rise. Companies operating in this market are likely to focus on innovation and development, investing in research to enhance the performance and reliability of their splicing products. This focus on innovation is crucial for meeting the diverse needs of different applications and ensuring the market's sustained growth. The projected growth of the Global Parallel Splicing Market underscores its importance in supporting the infrastructure of modern electrical systems, providing the necessary technology and solutions to ensure efficient, reliable, and safe electrical connections.

| Report Metric | Details |

| Report Name | Parallel Splicing Market |

| Accounted market size in year | US$ 257 million |

| Forecasted market size in 2031 | US$ 379 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TE Connectivity, Molex, Japan Solderless Terminals, Panduit, ABB, Hoffman Products, Longyi Terminals, WXManen, Keystone, Blockmaster Electronics, Cambion |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |