What is Thermal Absorption Dryer - Global Market?

Thermal absorption dryers are essential components in various industrial processes, designed to remove moisture from compressed air systems. These dryers operate by using a desiccant material that absorbs moisture from the air, ensuring that the air is dry and suitable for use in sensitive applications. The global market for thermal absorption dryers is expanding due to the increasing demand for efficient and reliable air drying solutions across various industries. As industries continue to modernize and adopt more advanced technologies, the need for high-quality compressed air systems becomes more critical, driving the growth of the thermal absorption dryer market. These dryers are particularly valued for their ability to maintain consistent performance even in challenging environments, making them a preferred choice for industries that require high levels of precision and reliability. The market is characterized by a diverse range of products, catering to different industrial needs and specifications, which further fuels its growth. As a result, manufacturers are continually innovating to improve the efficiency and effectiveness of these dryers, ensuring they meet the evolving demands of the global market.

Intermittent, Continuous in the Thermal Absorption Dryer - Global Market:

In the realm of thermal absorption dryers, two primary operational modes are prevalent: intermittent and continuous. Intermittent thermal absorption dryers are designed to operate in cycles, where the drying process is periodically halted to allow for the regeneration of the desiccant material. This mode is particularly beneficial in applications where the demand for dry air is not constant, allowing for energy savings and reduced operational costs. Intermittent dryers are often used in smaller-scale operations or in industries where the air demand fluctuates significantly. They offer the advantage of lower initial investment costs and are easier to maintain due to their simpler design. However, the cyclic nature of their operation can lead to variations in air quality, which may not be suitable for all applications. On the other hand, continuous thermal absorption dryers provide a steady supply of dry air, making them ideal for applications where a constant and reliable air supply is crucial. These dryers operate without interruption, ensuring that the desiccant material is continuously regenerated, often through a dual-tower system where one tower is drying the air while the other is being regenerated. This design ensures a consistent output of dry air, which is essential in industries where even minor fluctuations in air quality can lead to significant issues. Continuous dryers are typically used in large-scale industrial operations where the demand for dry air is high and constant. They are more complex and require a higher initial investment compared to intermittent dryers, but they offer superior performance and reliability. The choice between intermittent and continuous thermal absorption dryers largely depends on the specific needs of the application. Industries with variable air demand may benefit from the cost-effectiveness and simplicity of intermittent dryers, while those requiring a constant supply of high-quality air may find continuous dryers to be the better option. Additionally, advancements in technology are leading to the development of hybrid systems that combine the benefits of both intermittent and continuous modes, offering greater flexibility and efficiency. These hybrid systems are gaining popularity as they provide a more tailored solution to the diverse needs of modern industrial processes. Overall, the global market for thermal absorption dryers is witnessing significant growth, driven by the increasing demand for efficient and reliable air drying solutions. As industries continue to evolve and adopt more advanced technologies, the need for high-quality compressed air systems becomes more critical, further fueling the demand for both intermittent and continuous thermal absorption dryers. Manufacturers are continually innovating to improve the efficiency and effectiveness of these dryers, ensuring they meet the evolving demands of the global market. This ongoing innovation is expected to drive further growth in the market, as industries seek to optimize their operations and improve overall efficiency.

Automotive, Oil and Gas, Food and Beverages, Metal and Machinery, Pharmaceuticals, Others in the Thermal Absorption Dryer - Global Market:

Thermal absorption dryers play a crucial role in various industries, including automotive, oil and gas, food and beverages, metal and machinery, pharmaceuticals, and others. In the automotive industry, these dryers are essential for ensuring that compressed air systems used in manufacturing processes are free from moisture, which can lead to corrosion and damage to sensitive components. The use of dry air is critical in painting and coating applications, where moisture can cause defects and compromise the quality of the finish. In the oil and gas industry, thermal absorption dryers are used to ensure that the compressed air used in drilling and extraction processes is dry and free from contaminants. This is essential for maintaining the integrity of equipment and preventing costly downtime due to moisture-related issues. In the food and beverages industry, thermal absorption dryers are used to ensure that compressed air used in packaging and processing is free from moisture, which can lead to contamination and spoilage. The use of dry air is critical in maintaining the quality and safety of food products, making these dryers an essential component of modern food processing operations. In the metal and machinery industry, thermal absorption dryers are used to ensure that compressed air used in machining and fabrication processes is dry and free from moisture, which can lead to corrosion and damage to equipment. The use of dry air is critical in maintaining the precision and quality of metal components, making these dryers an essential component of modern manufacturing operations. In the pharmaceutical industry, thermal absorption dryers are used to ensure that compressed air used in manufacturing and packaging processes is dry and free from contaminants. This is essential for maintaining the quality and safety of pharmaceutical products, making these dryers an essential component of modern pharmaceutical operations. In addition to these industries, thermal absorption dryers are also used in a variety of other applications, including electronics manufacturing, chemical processing, and more. The versatility and reliability of these dryers make them a preferred choice for industries that require high levels of precision and reliability in their operations. Overall, the global market for thermal absorption dryers is witnessing significant growth, driven by the increasing demand for efficient and reliable air drying solutions across various industries. As industries continue to evolve and adopt more advanced technologies, the need for high-quality compressed air systems becomes more critical, further fueling the demand for thermal absorption dryers. Manufacturers are continually innovating to improve the efficiency and effectiveness of these dryers, ensuring they meet the evolving demands of the global market. This ongoing innovation is expected to drive further growth in the market, as industries seek to optimize their operations and improve overall efficiency.

Thermal Absorption Dryer - Global Market Outlook:

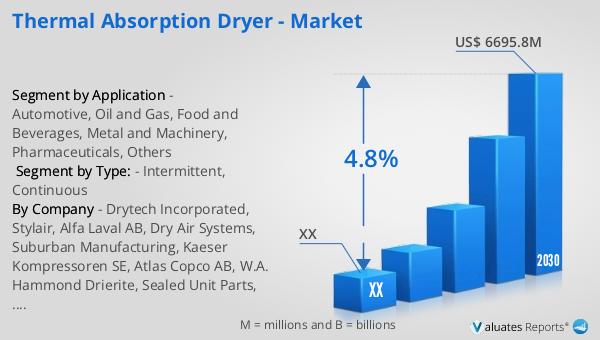

In 2023, the global market for thermal absorption dryers was valued at approximately $4,836 million. Looking ahead, this market is projected to grow, reaching an estimated size of $6,695.8 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for efficient and reliable air drying solutions across various industries. As industries continue to modernize and adopt more advanced technologies, the need for high-quality compressed air systems becomes more critical, driving the growth of the thermal absorption dryer market. The market is characterized by a diverse range of products, catering to different industrial needs and specifications, which further fuels its growth. As a result, manufacturers are continually innovating to improve the efficiency and effectiveness of these dryers, ensuring they meet the evolving demands of the global market. This ongoing innovation is expected to drive further growth in the market, as industries seek to optimize their operations and improve overall efficiency.

| Report Metric | Details |

| Report Name | Thermal Absorption Dryer - Market |

| Forecasted market size in 2030 | US$ 6695.8 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Drytech Incorporated, Stylair, Alfa Laval AB, Dry Air Systems, Suburban Manufacturing, Kaeser Kompressoren SE, Atlas Copco AB, W.A. Hammond Drierite, Sealed Unit Parts, Bry-Air, Altec AIR, Koby, Munters, Comco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |