What is Cereal Dryer - Global Market?

Cereal dryers are essential machines in the global agricultural market, designed to remove moisture from cereal grains such as wheat, corn, rice, and barley. These dryers play a crucial role in ensuring the quality and longevity of cereals by preventing spoilage and maintaining nutritional value. The global market for cereal dryers is driven by the increasing demand for efficient post-harvest processing technologies, which help in reducing losses and improving the quality of grains. As the global population continues to grow, the demand for food, particularly cereals, is on the rise, necessitating advanced drying technologies. Cereal dryers come in various types, including batch and continuous flow dryers, each suited for different scales of operation and types of cereals. The market is also influenced by technological advancements that aim to enhance energy efficiency and reduce operational costs. Manufacturers are focusing on developing dryers that are not only efficient but also environmentally friendly, aligning with global sustainability goals. The cereal dryer market is expected to expand as more regions adopt modern agricultural practices and invest in advanced machinery to boost productivity and ensure food security.

Cross-flow, Down-stream, Mixed-flow in the Cereal Dryer - Global Market:

In the global cereal dryer market, different drying technologies are employed to cater to various needs and scales of operation. Cross-flow dryers are among the most common types, where the air flows perpendicular to the grain flow. This method is efficient for drying large quantities of grain and is widely used in commercial settings. Cross-flow dryers are known for their uniform drying capabilities, as the grains are exposed to consistent airflow, ensuring even moisture removal. However, one of the challenges with cross-flow dryers is the potential for uneven drying if the airflow is not properly managed, which can lead to over-drying or under-drying of certain grain sections. Down-stream dryers, on the other hand, involve air flowing in the same direction as the grain. This method is particularly effective for grains that require gentle drying to preserve their quality and nutritional content. Down-stream dryers are often used for sensitive grains that are prone to damage under high temperatures or rapid drying conditions. The advantage of down-stream drying is its ability to maintain the integrity of the grain, although it may require longer drying times compared to other methods. Mixed-flow dryers combine elements of both cross-flow and down-stream drying techniques. In mixed-flow dryers, the grains are exposed to air that flows in multiple directions, allowing for more uniform drying and greater flexibility in handling different types of cereals. This method is particularly beneficial for operations that process a variety of grains, as it can be adjusted to suit the specific drying requirements of each type. Mixed-flow dryers are known for their versatility and efficiency, making them a popular choice in regions with diverse cereal production. The global market for cereal dryers is witnessing a shift towards more advanced and automated systems that incorporate digital controls and monitoring capabilities. These innovations allow for precise control over drying parameters, ensuring optimal moisture removal while minimizing energy consumption. As the demand for high-quality cereals continues to rise, the adoption of advanced drying technologies is expected to grow, driving the expansion of the cereal dryer market. Manufacturers are also focusing on developing dryers that are compatible with renewable energy sources, such as solar and biomass, to reduce the environmental impact of drying operations. This trend is particularly significant in regions with abundant renewable resources, where sustainable practices are becoming increasingly important. Overall, the global cereal dryer market is characterized by a diverse range of technologies and innovations aimed at improving efficiency, reducing costs, and enhancing the quality of dried cereals. As the market continues to evolve, the adoption of advanced drying technologies is expected to play a crucial role in meeting the growing demand for high-quality cereals worldwide.

Agriculture, Industry, Others in the Cereal Dryer - Global Market:

Cereal dryers are utilized in various sectors, including agriculture, industry, and other areas, each with specific requirements and applications. In agriculture, cereal dryers are primarily used to ensure the safe storage and preservation of harvested grains. By reducing the moisture content of cereals, these dryers prevent spoilage and fungal growth, which can lead to significant post-harvest losses. In many regions, particularly those with humid climates, cereal dryers are essential for maintaining the quality and marketability of grains. Farmers and agricultural cooperatives invest in cereal dryers to enhance their productivity and ensure a steady supply of high-quality cereals to the market. In the industrial sector, cereal dryers are used in the processing and manufacturing of various cereal-based products. Industries that produce breakfast cereals, snacks, and other grain-based foods rely on efficient drying technologies to maintain the quality and consistency of their products. Industrial cereal dryers are designed to handle large volumes of grain and are equipped with advanced features to ensure precise control over drying parameters. These dryers are crucial for meeting the stringent quality standards required in the food industry, where consistency and safety are paramount. Beyond agriculture and industry, cereal dryers find applications in other areas such as research and development, where they are used to study the drying characteristics of different grains and develop new drying technologies. Research institutions and universities utilize cereal dryers to conduct experiments and gather data that can inform the development of more efficient and sustainable drying methods. Additionally, cereal dryers are used in seed processing, where they help in preparing seeds for storage and planting by reducing their moisture content to optimal levels. This application is particularly important for seed banks and agricultural research centers that focus on preserving genetic diversity and developing new crop varieties. Overall, the usage of cereal dryers in agriculture, industry, and other areas highlights their importance in ensuring the quality, safety, and sustainability of cereal production and processing. As the demand for high-quality cereals continues to grow, the adoption of advanced drying technologies is expected to increase, driving the expansion of the cereal dryer market across various sectors.

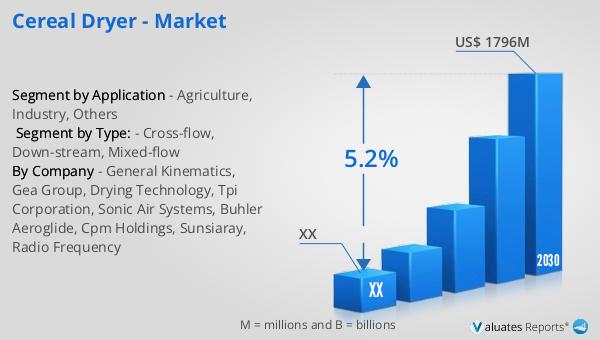

Cereal Dryer - Global Market Outlook:

The global market for cereal dryers was valued at approximately $1,263 million in 2023, with projections indicating a growth to around $1,796 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.2% during the forecast period from 2024 to 2030. This market expansion is driven by the increasing demand for efficient agricultural machinery, which encompasses a wide range of equipment used in the cultivation, processing, and treatment of agricultural products. Agricultural machinery, including cereal dryers, plays a vital role in enhancing productivity and ensuring the quality of agricultural outputs. As the global population continues to rise, the need for advanced agricultural technologies becomes more pressing, driving investments in machinery that can improve efficiency and reduce post-harvest losses. Cereal dryers, in particular, are essential for maintaining the quality and longevity of grains, which are staple foods for a significant portion of the world's population. The market outlook for cereal dryers reflects the broader trends in the agricultural sector, where there is a growing emphasis on sustainability, efficiency, and innovation. Manufacturers are focusing on developing dryers that are not only effective but also environmentally friendly, aligning with global efforts to reduce the carbon footprint of agricultural practices. As the market continues to evolve, the adoption of advanced drying technologies is expected to play a crucial role in meeting the increasing demand for high-quality cereals and supporting the growth of the global cereal dryer market.

| Report Metric | Details |

| Report Name | Cereal Dryer - Market |

| Forecasted market size in 2030 | US$ 1796 million |

| CAGR | 5.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | General Kinematics, Gea Group, Drying Technology, Tpi Corporation, Sonic Air Systems, Buhler Aeroglide, Cpm Holdings, Sunsiaray, Radio Frequency |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |