What is Global Sliding Door Hardware Market?

The Global Sliding Door Hardware Market is a dynamic and evolving sector that encompasses the components and mechanisms used in the installation and operation of sliding doors. These doors, which glide horizontally along a track, are popular for their space-saving benefits and modern aesthetic appeal. The market includes a variety of hardware components such as tracks, rollers, handles, locks, and other accessories that facilitate the smooth and efficient functioning of sliding doors. This market is driven by the increasing demand for space optimization in both residential and commercial buildings, as well as the growing preference for aesthetically pleasing and functional architectural solutions. Technological advancements and innovations in materials have further propelled the market, offering enhanced durability, ease of installation, and improved functionality. The market is also influenced by trends in interior design, with consumers seeking sleek and minimalist designs that complement contemporary living spaces. As urbanization continues to rise globally, the demand for efficient space utilization solutions like sliding doors is expected to grow, making the Global Sliding Door Hardware Market a significant player in the construction and interior design industries.

Wood Sliding Door Hardware, Glass Sliding Door Hardware, Aluminum/Metal Sliding Door Hardware, PVC Sliding Door Hardware in the Global Sliding Door Hardware Market:

Wood Sliding Door Hardware is a crucial segment within the Global Sliding Door Hardware Market, offering a blend of traditional aesthetics and modern functionality. Wood sliding doors are favored for their natural beauty and ability to add warmth to any space. The hardware for these doors typically includes wooden tracks, rollers, and handles that are designed to complement the door's material and style. These components are often crafted from high-quality wood or wood-like materials to ensure durability and smooth operation. The demand for wood sliding door hardware is driven by the popularity of rustic and farmhouse-style interiors, as well as the desire for sustainable and eco-friendly building materials. Glass Sliding Door Hardware, on the other hand, caters to the modern and minimalist design preferences. Glass sliding doors are popular in both residential and commercial settings for their ability to create a sense of openness and allow natural light to flow through spaces. The hardware for glass sliding doors includes specialized tracks, rollers, and handles that are designed to support the weight of the glass and ensure smooth and silent operation. These components are often made from stainless steel or aluminum to provide strength and corrosion resistance. Aluminum/Metal Sliding Door Hardware represents the largest segment in the market, known for its strength, durability, and versatility. Aluminum and metal sliding doors are widely used in commercial buildings, industrial facilities, and modern homes due to their sleek appearance and robust performance. The hardware for these doors includes heavy-duty tracks, rollers, and locking mechanisms that are designed to withstand frequent use and harsh environmental conditions. The popularity of aluminum and metal sliding door hardware is driven by the demand for low-maintenance and long-lasting solutions that can withstand the rigors of high-traffic areas. PVC Sliding Door Hardware is another important segment, offering cost-effective and lightweight solutions for residential and commercial applications. PVC sliding doors are known for their excellent insulation properties and resistance to moisture, making them ideal for use in bathrooms, kitchens, and other areas prone to humidity. The hardware for PVC sliding doors includes tracks, rollers, and handles made from durable plastic or metal components that are designed to provide smooth operation and long-lasting performance. The demand for PVC sliding door hardware is driven by the need for affordable and energy-efficient solutions that can enhance the comfort and functionality of living and working spaces.

Residential, Commercial in the Global Sliding Door Hardware Market:

The usage of Global Sliding Door Hardware Market in residential areas is primarily driven by the need for space-saving solutions and modern design aesthetics. Sliding doors are increasingly being used in homes to create flexible living spaces, allowing homeowners to easily partition or open up areas as needed. In small apartments and urban dwellings, sliding doors are particularly popular for their ability to maximize usable space and create a sense of openness. The hardware used in residential sliding doors is designed to be user-friendly and aesthetically pleasing, with a focus on smooth operation and quiet performance. Homeowners often choose sliding doors for their ability to seamlessly blend indoor and outdoor spaces, such as patios, balconies, and gardens, enhancing the overall living experience. In commercial settings, the Global Sliding Door Hardware Market plays a crucial role in providing efficient and functional solutions for a variety of applications. Sliding doors are commonly used in offices, retail stores, hotels, and restaurants to create flexible and adaptable spaces that can accommodate changing needs and customer preferences. The hardware used in commercial sliding doors is designed to withstand heavy use and provide reliable performance, with features such as automatic operation, enhanced security, and energy efficiency. In office environments, sliding doors are often used to create private meeting rooms or collaborative workspaces, allowing for easy reconfiguration and improved productivity. In retail settings, sliding doors are used to create inviting entrances and showcase products, while in hotels and restaurants, they are used to create elegant and functional spaces that enhance the guest experience. The demand for sliding door hardware in commercial applications is driven by the need for innovative and cost-effective solutions that can improve the functionality and aesthetics of business environments.

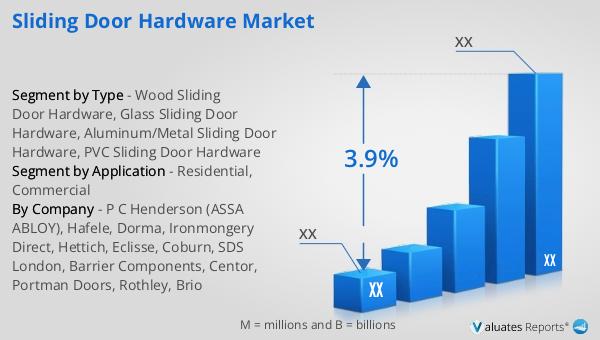

Global Sliding Door Hardware Market Outlook:

In 2024, the global market size for Sliding Door Hardware was valued at approximately US$ 2,407 million. It is projected to grow and reach around US$ 3,134 million by 2031, with a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold about 65% of the market share. Europe emerges as the largest market, accounting for roughly 35% of the global share, followed by China, which holds about 25%. Among the various product segments, Aluminum/Metal Sliding Door Hardware stands out as the largest, capturing approximately 35% of the market share. This growth is indicative of the increasing demand for durable and versatile sliding door solutions across different regions and applications. The preference for aluminum and metal hardware is driven by their strength, durability, and ability to withstand frequent use and harsh environmental conditions, making them ideal for both residential and commercial applications. As the market continues to evolve, manufacturers are focusing on innovation and quality to meet the diverse needs of consumers and maintain their competitive edge in this growing industry.

| Report Metric | Details |

| Report Name | Sliding Door Hardware Market |

| CAGR | 3.9% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | P C Henderson (ASSA ABLOY), Hafele, Dorma, Ironmongery Direct, Hettich, Eclisse, Coburn, SDS London, Barrier Components, Centor, Portman Doors, Rothley, Brio |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |