What is Global Polymeric Membrane for Separation Market?

The Global Polymeric Membrane for Separation Market is a specialized segment within the broader field of membrane technology, focusing on the use of polymeric materials to create membranes that facilitate the separation of different components in a mixture. These membranes are crucial in various industrial processes, including water treatment, gas separation, and chemical processing. Polymeric membranes are favored for their versatility, cost-effectiveness, and efficiency in separating substances at a molecular level. They are designed to selectively allow certain molecules to pass through while blocking others, making them essential in applications where purity and precision are paramount. The market for these membranes is driven by the increasing demand for clean water, the need for efficient gas separation technologies, and the growing emphasis on sustainable and environmentally friendly industrial processes. As industries continue to seek innovative solutions to improve efficiency and reduce environmental impact, the demand for polymeric membranes is expected to grow, offering significant opportunities for manufacturers and researchers in the field. The market is characterized by continuous advancements in material science and engineering, leading to the development of more robust and efficient membranes that can withstand harsh operating conditions and deliver superior performance.

Hollow Fiber, Spiral Wound, Others in the Global Polymeric Membrane for Separation Market:

In the Global Polymeric Membrane for Separation Market, different configurations of membranes are utilized, each offering unique advantages and applications. Hollow fiber membranes are one of the most prevalent types, known for their high surface area-to-volume ratio, which allows for efficient separation processes. These membranes consist of numerous tiny, hollow fibers bundled together, providing a large surface area for separation within a compact space. This design makes them ideal for applications requiring high throughput and efficiency, such as water purification and gas separation. The hollow fiber configuration is particularly advantageous in scenarios where space is limited, and high performance is required. Spiral wound membranes, on the other hand, are constructed by winding flat membrane sheets around a central tube, creating a compact and efficient design. This configuration is widely used in reverse osmosis and nanofiltration processes, where high pressure and efficient separation are necessary. Spiral wound membranes are favored for their ability to handle large volumes of liquid and their robustness in various operating conditions. They are commonly used in water desalination, wastewater treatment, and chemical processing industries. Other configurations in the polymeric membrane market include plate and frame, tubular, and capillary membranes, each offering specific benefits tailored to different industrial needs. Plate and frame membranes are known for their ease of cleaning and maintenance, making them suitable for applications where fouling is a concern. Tubular membranes, with their larger diameter, are often used in applications involving viscous fluids or high solid content, such as in the food and beverage industry. Capillary membranes, similar to hollow fibers but with a larger diameter, are used in applications requiring moderate separation efficiency and ease of handling. The choice of membrane configuration depends on various factors, including the nature of the feed stream, the desired separation efficiency, and the specific requirements of the application. Each configuration offers distinct advantages, and the selection process involves careful consideration of the operational parameters and the desired outcome. As the demand for efficient and sustainable separation technologies continues to grow, the development and optimization of these membrane configurations remain a key focus for researchers and manufacturers in the field. The ongoing advancements in material science and engineering are expected to lead to the creation of more efficient and durable membranes, capable of meeting the evolving needs of various industries.

Isolation of Inert N2 from Air, H2 Recovery, CO2 Removal from Natural Gas, Vapor/Nitrogen Separation, Other Applications in the Global Polymeric Membrane for Separation Market:

The Global Polymeric Membrane for Separation Market finds extensive usage across various applications, each leveraging the unique properties of polymeric membranes to achieve efficient and precise separation. In the isolation of inert nitrogen (N2) from air, polymeric membranes play a crucial role by selectively allowing nitrogen to pass through while retaining other gases. This application is vital in industries where nitrogen is used as a protective or inert atmosphere, such as in food packaging and chemical manufacturing. The ability of polymeric membranes to efficiently separate nitrogen from air makes them an essential component in nitrogen generation systems, offering a cost-effective and reliable solution for industries requiring high-purity nitrogen. In hydrogen (H2) recovery, polymeric membranes are employed to separate hydrogen from gas mixtures, a process critical in industries such as oil refining and ammonia production. The selective permeability of these membranes allows for the efficient recovery of hydrogen, which can then be reused in various industrial processes, enhancing overall efficiency and sustainability. The removal of carbon dioxide (CO2) from natural gas is another significant application of polymeric membranes. In this process, membranes are used to selectively separate CO2 from methane, the primary component of natural gas. This separation is crucial for improving the quality of natural gas and reducing its environmental impact when used as a fuel. Polymeric membranes offer an efficient and cost-effective solution for CO2 removal, contributing to cleaner energy production and reduced greenhouse gas emissions. In vapor/nitrogen separation, polymeric membranes are used to separate volatile organic compounds (VOCs) from nitrogen streams. This application is particularly important in industries such as petrochemicals and pharmaceuticals, where the recovery of VOCs is essential for both economic and environmental reasons. The ability of polymeric membranes to efficiently separate VOCs from nitrogen streams helps industries comply with environmental regulations while recovering valuable compounds for reuse. Other applications of polymeric membranes in the separation market include water treatment, where they are used to remove impurities and contaminants from water, and in the food and beverage industry, where they are employed in processes such as milk and juice clarification. The versatility and efficiency of polymeric membranes make them indispensable in a wide range of industrial applications, driving their demand and fostering innovation in the field. As industries continue to seek sustainable and efficient solutions for separation processes, the role of polymeric membranes is expected to expand, offering new opportunities for growth and development in the market.

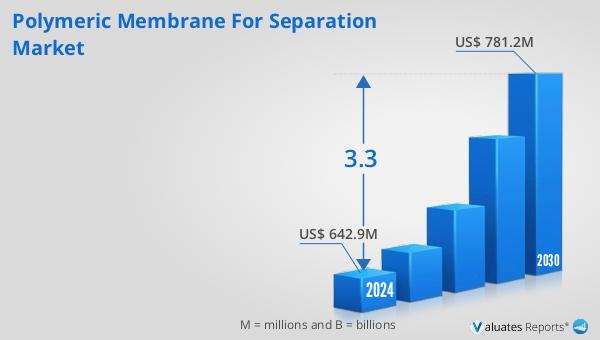

Global Polymeric Membrane for Separation Market Outlook:

In 2024, the global market size for Polymeric Membrane for Separation was valued at approximately US$ 662 million, with projections indicating it could reach around US$ 828 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold about 75% of the market share. North America emerges as the largest market, accounting for approximately 40% of the global share, followed by the Asia-Pacific region, which holds about 30%. In terms of product segmentation, Hollow Fiber stands out as the largest segment, capturing around 85% of the market share. This dominance is attributed to the high efficiency and versatility of hollow fiber membranes, which are widely used across various applications due to their superior performance and compact design. The market dynamics are influenced by the growing demand for efficient separation technologies, driven by the need for sustainable industrial processes and the increasing emphasis on environmental protection. As industries continue to prioritize efficiency and sustainability, the demand for polymeric membranes is expected to rise, offering significant opportunities for growth and innovation in the market.

| Report Metric | Details |

| Report Name | Polymeric Membrane for Separation Market |

| Forecasted market size in 2031 | approximately US$ 828 million |

| CAGR | 3.3% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Air Products, Air Liquide, UBE, Grasys, Evonik, Schlumberger, IGS, Honeywell, MTR, Borsig, Parker Hannifin, Tianbang, SSS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |