What is Global Pharmaceutical Grade Nicotinamide Mononucleotide Market?

The Global Pharmaceutical Grade Nicotinamide Mononucleotide (NMN) Market is a specialized segment within the broader pharmaceutical industry, focusing on the production and distribution of NMN, a compound that has gained significant attention for its potential health benefits. NMN is a derivative of niacin, a form of vitamin B3, and is considered a precursor to nicotinamide adenine dinucleotide (NAD+), a coenzyme involved in various metabolic processes. The market for pharmaceutical-grade NMN is driven by increasing consumer interest in health and wellness, particularly in anti-aging and longevity research. As scientific studies continue to explore the benefits of NMN in enhancing cellular energy production, improving metabolic health, and potentially extending lifespan, demand for high-quality NMN supplements is on the rise. This market is characterized by rigorous quality standards and regulatory requirements, ensuring that the NMN produced is of pharmaceutical grade, suitable for use in health products and other applications. The global reach of this market reflects a growing awareness and acceptance of NMN's potential benefits, with manufacturers and suppliers expanding their operations to meet the increasing demand from health-conscious consumers worldwide.

Concentration≥98%, Concentration<98% in the Global Pharmaceutical Grade Nicotinamide Mononucleotide Market:

In the Global Pharmaceutical Grade Nicotinamide Mononucleotide Market, the concentration of NMN is a critical factor that influences its application and efficacy. Products are typically categorized based on their concentration levels, with two primary segments: Concentration≥98% and Concentration<98%. The Concentration≥98% segment represents NMN products that have a purity level of 98% or higher. This high-purity NMN is often preferred for pharmaceutical applications due to its superior quality and effectiveness. High-purity NMN is believed to offer more consistent and reliable results, making it a popular choice among consumers seeking the maximum potential benefits of NMN supplementation. The production of high-purity NMN involves advanced manufacturing processes and stringent quality control measures to ensure that the final product meets the required standards. On the other hand, the Concentration<98% segment includes NMN products with a purity level below 98%. While these products may be more affordable, they may not offer the same level of efficacy as their higher-purity counterparts. The lower concentration NMN products are often used in applications where cost considerations are a priority, and the highest level of purity is not essential. Both segments play a vital role in the overall market, catering to different consumer needs and preferences. The choice between high-purity and lower-purity NMN products depends on various factors, including the intended use, budget, and individual health goals. As the market continues to evolve, manufacturers are investing in research and development to improve the production processes and enhance the quality of NMN products across all concentration levels. This ongoing innovation is expected to drive further growth in the market, as consumers become more informed about the benefits of NMN and seek products that align with their specific health and wellness objectives. The competition between high-purity and lower-purity NMN products also encourages manufacturers to differentiate their offerings through unique formulations, packaging, and marketing strategies. By understanding the nuances of NMN concentration levels, consumers can make informed decisions about which products best suit their needs, contributing to the overall growth and diversification of the Global Pharmaceutical Grade Nicotinamide Mononucleotide Market.

Health Products, Others in the Global Pharmaceutical Grade Nicotinamide Mononucleotide Market:

The usage of Global Pharmaceutical Grade Nicotinamide Mononucleotide Market extends to various areas, with health products being one of the most prominent applications. NMN is increasingly incorporated into dietary supplements and functional foods aimed at promoting overall health and well-being. The compound's potential to enhance cellular energy production and support metabolic health makes it an attractive ingredient for health-conscious consumers. In the realm of health products, NMN is often marketed for its anti-aging properties, as it is believed to help maintain youthful energy levels and improve skin health. Additionally, NMN supplements are popular among individuals seeking to boost their physical performance and endurance, as well as those looking to support cognitive function and mental clarity. The versatility of NMN allows it to be used in various formulations, including capsules, powders, and beverages, catering to different consumer preferences and lifestyles. Beyond health products, NMN finds applications in other areas, such as cosmetics and skincare. The compound's potential to improve skin elasticity and reduce the appearance of fine lines and wrinkles has led to its inclusion in anti-aging creams and serums. In the cosmetics industry, NMN is valued for its ability to support skin health at a cellular level, offering a natural and effective solution for maintaining a youthful appearance. Furthermore, NMN is being explored for its potential therapeutic applications in addressing age-related health issues. Research into the compound's effects on conditions such as cardiovascular health, neurodegenerative diseases, and metabolic disorders is ongoing, with promising results that could expand the scope of NMN's usage in the future. As scientific understanding of NMN's benefits continues to grow, the demand for pharmaceutical-grade NMN products is expected to increase, driving innovation and development in the market. The diverse applications of NMN highlight its potential as a versatile and valuable ingredient in the health and wellness industry, offering consumers a range of options to support their health goals.

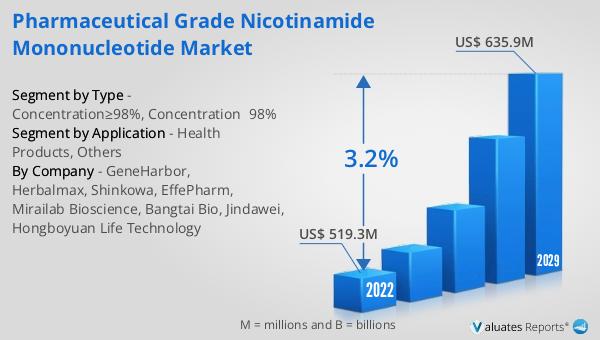

Global Pharmaceutical Grade Nicotinamide Mononucleotide Market Outlook:

The global market for Pharmaceutical Grade Nicotinamide Mononucleotide was valued at US$ 542 million in the year 2024 and is projected to reach a revised size of US$ 673 million by 2031, growing at a CAGR of 3.2% during the forecast period. This market outlook indicates a steady growth trajectory, driven by increasing consumer awareness and demand for NMN products. The projected growth reflects the expanding interest in health and wellness, particularly in the context of aging and longevity. As more consumers seek natural and effective solutions to support their health, the demand for high-quality NMN supplements is expected to rise. The market's growth is also supported by ongoing research and development efforts aimed at enhancing the efficacy and accessibility of NMN products. Manufacturers are investing in advanced production technologies and innovative formulations to meet the evolving needs of consumers. The competitive landscape of the market is characterized by a diverse range of players, from established pharmaceutical companies to emerging startups, all vying for a share of the growing demand for NMN products. As the market continues to evolve, companies are focusing on differentiation strategies, such as unique product offerings and targeted marketing campaigns, to capture consumer attention and drive sales. The global reach of the market underscores the widespread appeal of NMN, with consumers from various regions seeking the benefits of this promising compound. Overall, the market outlook for Pharmaceutical Grade Nicotinamide Mononucleotide suggests a positive and dynamic future, with ample opportunities for growth and innovation.

| Report Metric | Details |

| Report Name | Pharmaceutical Grade Nicotinamide Mononucleotide Market |

| Accounted market size in year | US$ 542 million |

| Forecasted market size in 2031 | US$ 673 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GeneHarbor, Herbalmax, Shinkowa, EffePharm, Mirailab Bioscience, Bangtai Bio, Jindawei, Hongboyuan Life Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |