What is Global Inorganic Composite Crystal Plate Market?

The Global Inorganic Composite Crystal Plate Market is a specialized segment within the broader materials industry, focusing on the production and application of inorganic composite crystal plates. These plates are engineered materials composed of inorganic compounds that are structured in a crystalline form. They are known for their exceptional properties, such as high thermal stability, mechanical strength, and resistance to chemical corrosion. These characteristics make them suitable for a wide range of applications across various industries. The market for these materials is driven by the increasing demand for advanced materials that can withstand extreme conditions and provide enhanced performance in critical applications. Industries such as electronics, aerospace, and construction are major consumers of inorganic composite crystal plates, utilizing them in products ranging from semiconductors to structural components. The market is characterized by continuous innovation and development, as manufacturers strive to improve the properties and reduce the costs of these materials. As technology advances and new applications are discovered, the Global Inorganic Composite Crystal Plate Market is expected to grow, offering new opportunities for businesses and contributing to technological progress across multiple sectors.

Hot Pressing, Chemical Vapor Deposition in the Global Inorganic Composite Crystal Plate Market:

Hot pressing and chemical vapor deposition are two critical processes in the production of inorganic composite crystal plates, each offering unique advantages and challenges. Hot pressing is a technique that involves applying heat and pressure to a material to form a dense, solid structure. This process is particularly useful for creating composite materials, as it allows for the bonding of different components at a molecular level, resulting in a material with enhanced properties. In the context of inorganic composite crystal plates, hot pressing is used to achieve high density and uniformity, which are essential for applications requiring high mechanical strength and thermal stability. The process involves placing the material in a mold and applying pressure while heating it to a specific temperature. This causes the particles to fuse together, eliminating voids and defects that could compromise the material's performance. One of the main advantages of hot pressing is its ability to produce materials with a high degree of precision and consistency, making it ideal for applications where reliability is critical. Chemical vapor deposition (CVD), on the other hand, is a process used to produce thin films and coatings of materials on a substrate. It involves the chemical reaction of gaseous precursors, which decompose or react on the surface of the substrate to form a solid material. CVD is widely used in the production of inorganic composite crystal plates due to its ability to create materials with excellent purity and uniformity. The process allows for precise control over the composition and thickness of the deposited material, enabling the production of plates with tailored properties for specific applications. CVD is particularly advantageous for creating materials with complex compositions or structures that would be difficult to achieve through other methods. It is also a versatile process that can be used to deposit a wide range of materials, including metals, ceramics, and semiconductors. Both hot pressing and CVD play a crucial role in the Global Inorganic Composite Crystal Plate Market, providing manufacturers with the tools needed to produce high-quality materials that meet the demands of modern technology. While hot pressing is ideal for creating bulk materials with high density and strength, CVD is better suited for producing thin films and coatings with precise properties. Together, these processes enable the production of a wide range of inorganic composite crystal plates, each designed to meet the specific needs of different industries. As the market continues to evolve, advancements in these technologies are expected to drive further innovation, leading to the development of new materials with even greater performance capabilities. The ongoing research and development in these areas highlight the importance of these processes in the advancement of material science and their contribution to the growth of the Global Inorganic Composite Crystal Plate Market.

Building, Transportation, Environmental Protection, Electric Power in the Global Inorganic Composite Crystal Plate Market:

The Global Inorganic Composite Crystal Plate Market finds extensive usage across various sectors, including building, transportation, environmental protection, and electric power, each benefiting from the unique properties of these materials. In the building industry, inorganic composite crystal plates are used for their durability and resistance to environmental factors. They are often employed in the construction of facades, roofing, and other structural components where long-term performance and minimal maintenance are crucial. The plates' ability to withstand harsh weather conditions and resist corrosion makes them an ideal choice for modern architectural designs that prioritize sustainability and longevity. In the transportation sector, these materials are utilized for their lightweight and high-strength characteristics. Inorganic composite crystal plates are used in the manufacturing of components for automobiles, aircraft, and trains, where reducing weight without compromising strength is essential for improving fuel efficiency and performance. The materials' thermal stability and resistance to wear also make them suitable for use in high-temperature environments, such as engine components and exhaust systems, where they help enhance the overall efficiency and lifespan of the vehicles. Environmental protection is another area where the Global Inorganic Composite Crystal Plate Market plays a significant role. These materials are used in the development of pollution control devices, such as filters and membranes, which require high chemical resistance and durability. The plates' ability to withstand aggressive chemical environments makes them ideal for use in water treatment facilities and air purification systems, where they help reduce the environmental impact of industrial processes and improve the quality of life. In the electric power industry, inorganic composite crystal plates are used in the production of components for power generation and distribution systems. Their excellent electrical insulation properties and thermal stability make them suitable for use in transformers, insulators, and other critical components that require reliable performance under high-voltage conditions. The materials' resistance to thermal and mechanical stress also ensures the longevity and safety of power systems, contributing to the overall efficiency and reliability of the electric grid. Overall, the Global Inorganic Composite Crystal Plate Market offers a wide range of applications across various industries, each benefiting from the unique properties of these advanced materials. As technology continues to advance and new challenges arise, the demand for high-performance materials like inorganic composite crystal plates is expected to grow, driving further innovation and development in this dynamic market.

Global Inorganic Composite Crystal Plate Market Outlook:

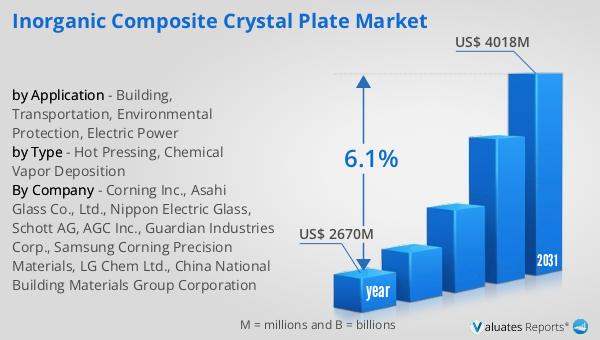

The global market for Inorganic Composite Crystal Plate was valued at approximately $2.67 billion in 2024, and it is anticipated to expand to a revised size of around $4.018 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. This market outlook reflects the increasing demand for advanced materials that offer superior performance in various applications. The projected growth is driven by the expanding use of inorganic composite crystal plates in industries such as electronics, construction, and transportation, where their unique properties provide significant advantages. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties and reducing the costs of these materials. As manufacturers continue to innovate and explore new applications, the Global Inorganic Composite Crystal Plate Market is poised for sustained growth, offering new opportunities for businesses and contributing to technological progress across multiple sectors. The anticipated increase in market size underscores the importance of these materials in modern technology and their potential to drive future advancements in various industries.

| Report Metric | Details |

| Report Name | Inorganic Composite Crystal Plate Market |

| Accounted market size in year | US$ 2670 million |

| Forecasted market size in 2031 | US$ 4018 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Corning Inc., Asahi Glass Co., Ltd., Nippon Electric Glass, Schott AG, AGC Inc., Guardian Industries Corp., Samsung Corning Precision Materials, LG Chem Ltd., China National Building Materials Group Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |