What is Global Feed Grade DL-Methionine Market?

The Global Feed Grade DL-Methionine Market is a specialized segment within the broader animal feed industry, focusing on the production and distribution of DL-Methionine, an essential amino acid used primarily in animal nutrition. DL-Methionine is crucial for the growth and health of livestock, particularly poultry and swine, as it helps in protein synthesis and improves feed efficiency. The market for this compound is driven by the increasing demand for high-quality animal protein, which in turn is fueled by the growing global population and rising income levels. As consumers become more health-conscious, there is a heightened demand for meat products that are not only safe but also nutritious, leading to an increased need for effective animal feed additives like DL-Methionine. The market is characterized by a few key players who dominate the production and supply chain, ensuring that the quality and efficacy of DL-Methionine meet industry standards. Technological advancements and innovations in production processes are also contributing to the market's growth, making DL-Methionine more accessible and affordable for feed manufacturers worldwide. As the livestock industry continues to expand, the Global Feed Grade DL-Methionine Market is expected to see sustained growth, driven by both demand and innovation.

Solid State, Liquid State in the Global Feed Grade DL-Methionine Market:

In the Global Feed Grade DL-Methionine Market, the product is available in two primary forms: solid state and liquid state, each with its own set of advantages and applications. The solid state form of DL-Methionine is typically in the form of a crystalline powder, which is highly stable and easy to handle. This form is particularly favored in regions where storage conditions might not be optimal, as it has a longer shelf life and is less susceptible to degradation. The solid state DL-Methionine is often used in premixes and compound feeds, where it can be easily blended with other feed ingredients. Its stability ensures that the nutritional value is maintained throughout the feed production process, making it a reliable choice for feed manufacturers. On the other hand, the liquid state DL-Methionine is a more recent innovation, offering certain advantages in terms of ease of mixing and uniform distribution in feed. This form is particularly beneficial in large-scale feed operations where precision and consistency are crucial. Liquid DL-Methionine can be directly added to feed formulations, ensuring that the amino acid is evenly distributed throughout the feed. This can lead to improved feed conversion ratios and better overall animal performance. Additionally, the liquid form can be more cost-effective in certain applications, as it reduces the need for additional processing steps. However, it requires careful handling and storage to prevent degradation, as it is more sensitive to environmental conditions compared to its solid counterpart. The choice between solid and liquid DL-Methionine often depends on the specific needs of the feed operation, including factors such as scale, storage capabilities, and desired outcomes. Both forms play a crucial role in the Global Feed Grade DL-Methionine Market, catering to the diverse needs of the animal feed industry. As the market continues to evolve, innovations in both solid and liquid forms of DL-Methionine are expected to enhance their efficacy and application, further driving the growth of this essential market segment.

Broiler Feed, Pig Feed, Other in the Global Feed Grade DL-Methionine Market:

The usage of Global Feed Grade DL-Methionine Market is particularly significant in areas such as broiler feed, pig feed, and other livestock feeds. In broiler feed, DL-Methionine is essential for promoting rapid growth and improving feed efficiency. Broilers, or meat chickens, require a balanced diet rich in amino acids to achieve optimal growth rates and meat quality. DL-Methionine helps in protein synthesis, ensuring that the birds develop strong muscles and healthy tissues. This not only improves the overall health and productivity of the broilers but also enhances the quality of the meat, making it more appealing to consumers. In pig feed, DL-Methionine plays a similar role, supporting growth and improving feed conversion ratios. Pigs, like broilers, require a diet that is rich in essential amino acids to support their rapid growth and development. DL-Methionine helps in the efficient utilization of feed, reducing waste and improving the overall profitability of pig farming operations. Additionally, it supports the immune system of pigs, helping them to resist diseases and maintain good health. Beyond broilers and pigs, DL-Methionine is also used in other livestock feeds, including dairy cattle, aquaculture, and pet food. In dairy cattle, it supports milk production and improves the overall health of the herd. In aquaculture, DL-Methionine is used to enhance the growth and health of fish and shrimp, ensuring that they reach market size more quickly and efficiently. In pet food, it is used to ensure that pets receive a balanced diet that supports their overall health and well-being. The versatility and efficacy of DL-Methionine make it an indispensable component of modern animal nutrition, driving its demand across various segments of the livestock industry.

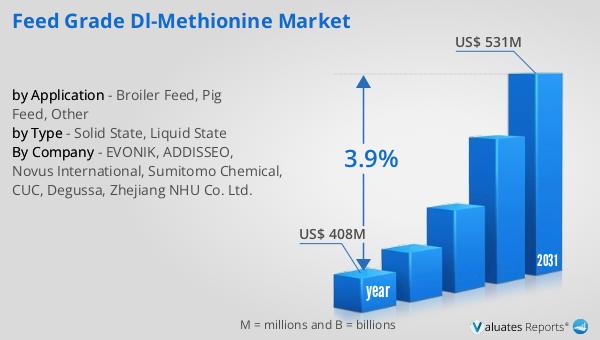

Global Feed Grade DL-Methionine Market Outlook:

The global market for Feed Grade DL-Methionine was valued at approximately $408 million in 2024, and it is anticipated to grow to a revised size of around $531 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. This upward trajectory is indicative of the increasing demand for DL-Methionine in animal nutrition, driven by the need for efficient and effective feed additives that support the growth and health of livestock. As the global population continues to rise, so does the demand for high-quality animal protein, which in turn fuels the need for feed additives like DL-Methionine. The market's growth is also supported by advancements in production technologies and innovations in feed formulations, which make DL-Methionine more accessible and affordable for feed manufacturers. Additionally, the growing awareness of the benefits of DL-Methionine in improving feed efficiency and animal performance is contributing to its increased adoption across various segments of the livestock industry. As a result, the Global Feed Grade DL-Methionine Market is poised for sustained growth, driven by both demand and innovation.

| Report Metric | Details |

| Report Name | Feed Grade DL-Methionine Market |

| Accounted market size in year | US$ 408 million |

| Forecasted market size in 2031 | US$ 531 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EVONIK, ADDISSEO, Novus International, Sumitomo Chemical, CUC, Degussa, Zhejiang NHU Co. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |