What is Global Modified Bitumen Roofing System Market?

The Global Modified Bitumen Roofing System Market is a significant segment within the construction industry, focusing on roofing solutions that utilize modified bitumen. Modified bitumen is a type of asphalt product that has been enhanced with polymers to improve its performance characteristics, such as flexibility, durability, and resistance to weathering. This market is driven by the demand for robust and long-lasting roofing systems that can withstand various environmental conditions. Modified bitumen roofing systems are particularly popular in regions with extreme weather patterns, as they offer superior protection against elements like wind, rain, and UV radiation. The market encompasses a range of products, including SBS (Styrene-Butadiene-Styrene) and APP (Atactic Polypropylene) modified bitumen, each offering unique benefits. As urbanization and infrastructure development continue to rise globally, the demand for reliable roofing solutions is expected to grow, making the modified bitumen roofing system market a crucial area of focus for manufacturers and contractors alike. The market's growth is also supported by advancements in technology and materials, which enhance the performance and lifespan of these roofing systems, providing value to both residential and commercial property owners.

SBS Modified Bitumen, APP Modified Bitumen, Other in the Global Modified Bitumen Roofing System Market:

SBS Modified Bitumen, APP Modified Bitumen, and other variants play a pivotal role in the Global Modified Bitumen Roofing System Market, each offering distinct advantages tailored to specific needs. SBS Modified Bitumen is known for its exceptional flexibility and elasticity, making it ideal for environments where temperature fluctuations are common. This type of modified bitumen incorporates Styrene-Butadiene-Styrene, a synthetic rubber, which enhances its ability to expand and contract without cracking. This flexibility ensures that SBS modified bitumen can maintain its integrity over time, even in harsh weather conditions. It is often used in roofing systems where a high degree of movement is expected, such as in areas prone to seismic activity or where buildings experience significant thermal expansion and contraction. On the other hand, APP Modified Bitumen is renowned for its excellent resistance to UV radiation and high temperatures. By incorporating Atactic Polypropylene, a type of plastic, APP modified bitumen becomes more rigid and durable, making it suitable for regions with intense sunlight and heat. This rigidity provides a robust barrier against environmental elements, ensuring long-lasting protection for the structures it covers. APP modified bitumen is often preferred in commercial and industrial applications where durability and resistance to weathering are paramount. Beyond SBS and APP, other modified bitumen products are available, each designed to meet specific performance criteria. These may include hybrid systems that combine the benefits of both SBS and APP, offering a balance of flexibility and durability. Additionally, some modified bitumen products are enhanced with additional additives to improve specific properties, such as fire resistance or increased adhesion. The choice between SBS, APP, and other modified bitumen products depends largely on the specific requirements of the project, including the local climate, building design, and intended lifespan of the roofing system. As the Global Modified Bitumen Roofing System Market continues to evolve, manufacturers are investing in research and development to create innovative products that meet the changing needs of the construction industry. This includes the development of environmentally friendly options that reduce the carbon footprint of roofing systems while maintaining high performance standards. The versatility and adaptability of modified bitumen make it a preferred choice for a wide range of applications, ensuring its continued relevance in the global market.

Residential, Commercial Building, Industrial Building in the Global Modified Bitumen Roofing System Market:

The usage of Global Modified Bitumen Roofing System Market products spans across various sectors, including residential, commercial, and industrial buildings, each benefiting from the unique properties of modified bitumen. In residential applications, modified bitumen roofing systems are favored for their durability and ease of installation. Homeowners appreciate the long-lasting protection these systems provide against leaks and weather damage, ensuring the safety and comfort of their living spaces. The flexibility of SBS modified bitumen is particularly advantageous in residential settings, where roofs may need to accommodate slight movements due to temperature changes or structural shifts. Additionally, the aesthetic appeal of modified bitumen roofing, available in various colors and finishes, allows homeowners to enhance the curb appeal of their properties while ensuring robust protection. In commercial buildings, the demand for reliable and cost-effective roofing solutions drives the adoption of modified bitumen systems. Commercial properties, such as office buildings, retail centers, and warehouses, require roofing systems that can withstand heavy foot traffic, equipment loads, and exposure to harsh environmental conditions. APP modified bitumen is often the preferred choice in these settings due to its superior resistance to UV radiation and high temperatures, ensuring that the roofing system remains intact and functional over time. The ability to customize modified bitumen roofing systems to meet specific design and performance requirements makes them an attractive option for commercial property owners looking to maximize their investment. Industrial buildings, such as factories and manufacturing plants, also benefit significantly from the use of modified bitumen roofing systems. These environments often involve exposure to chemicals, extreme temperatures, and mechanical stress, necessitating a roofing solution that can endure such challenges. Modified bitumen's robustness and adaptability make it well-suited for industrial applications, providing a reliable barrier against environmental and operational hazards. The incorporation of additional additives in modified bitumen products can further enhance their resistance to fire, chemicals, and other industrial risks, ensuring the safety and longevity of the roofing system. As the Global Modified Bitumen Roofing System Market continues to expand, the versatility and performance of modified bitumen products will remain a key factor in their widespread adoption across residential, commercial, and industrial sectors. The ability to tailor these systems to meet specific needs, combined with ongoing advancements in materials and technology, ensures that modified bitumen roofing systems will continue to play a vital role in the construction industry.

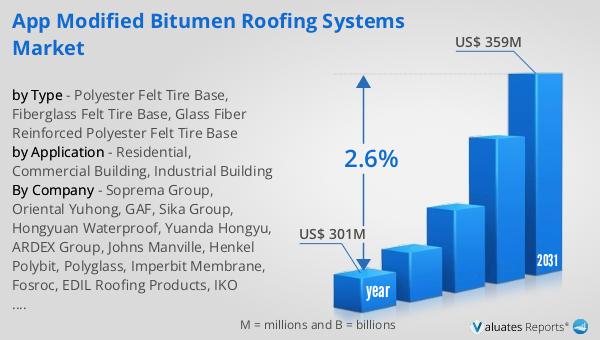

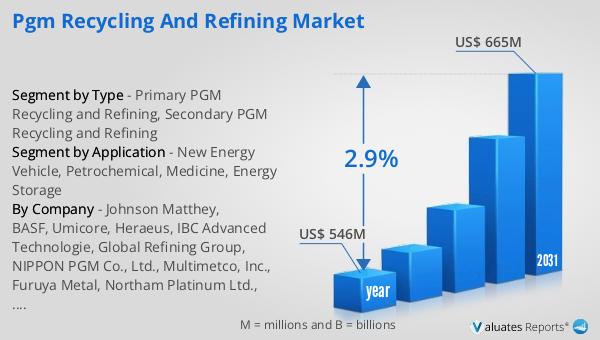

Global Modified Bitumen Roofing System Market Outlook:

The global market for Modified Bitumen Roofing System was valued at approximately $944 million in 2024, and it is anticipated to grow to a revised size of around $1,197 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.5% over the forecast period. This steady increase in market size reflects the rising demand for durable and efficient roofing solutions across various sectors. The growth is driven by several factors, including the increasing need for infrastructure development, urbanization, and the demand for energy-efficient and sustainable building materials. As more regions experience extreme weather conditions, the need for robust roofing systems that can withstand such challenges becomes more critical. Modified bitumen roofing systems, with their enhanced performance characteristics, are well-positioned to meet these demands. The market's expansion is also supported by technological advancements that improve the quality and lifespan of modified bitumen products, offering greater value to consumers. As the construction industry continues to evolve, the global market for modified bitumen roofing systems is expected to maintain its upward trajectory, driven by the ongoing need for reliable and high-performance roofing solutions.

| Report Metric | Details |

| Report Name | Modified Bitumen Roofing System Market |

| Accounted market size in year | US$ 944 million |

| Forecasted market size in 2031 | US$ 1197 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Soprema Group, Oriental Yuhong, GAF, Sika Group, Hongyuan Waterproof, CKS, Yuanda Hongyu, ARDEX Group, Tamko, Henkel Polybit, Polyglass, Imperbit Membrane, Fosroc, EDIL Roofing Products, IKO Industries, General Membrane, ChovA, Vetroasfalto, Bauder, Protecto Wrap, Johns Manville, Henry Company, CHENGTE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |