What is Global Bedsore Medicine Market?

The Global Bedsore Medicine Market is a specialized segment within the healthcare industry focused on the prevention and treatment of pressure ulcers, commonly known as bedsores. These painful skin injuries occur when prolonged pressure restricts blood flow to the skin, often affecting individuals who are bedridden or have limited mobility. The market encompasses a wide range of products and treatments designed to address different stages of bedsores, from early prevention to advanced wound care. This includes topical treatments, dressings, and advanced therapies that promote healing and prevent infection. The market is driven by an aging population, increasing awareness of patient care standards, and advancements in medical technology. Healthcare providers, caregivers, and patients are increasingly seeking effective solutions to manage and prevent bedsores, leading to a growing demand for innovative products. As the global population continues to age, the need for effective bedsore management solutions is expected to rise, making this market a critical component of the broader healthcare landscape. The Global Bedsore Medicine Market is characterized by ongoing research and development efforts aimed at improving treatment outcomes and enhancing patient quality of life.

Dressing, Antibiotic Ointment in the Global Bedsore Medicine Market:

In the Global Bedsore Medicine Market, dressing and antibiotic ointments play a crucial role in the management and treatment of pressure ulcers. Dressings are essential in protecting the wound from external contaminants, maintaining a moist environment conducive to healing, and absorbing exudate. There are various types of dressings available, each designed to cater to different stages and severities of bedsores. Hydrocolloid dressings, for instance, are used for mild to moderate ulcers and provide a moist environment that facilitates autolytic debridement. Foam dressings are highly absorbent and are suitable for wounds with moderate to heavy exudate, while alginate dressings, derived from seaweed, are used for wounds with significant drainage. Transparent film dressings are another option, allowing for easy monitoring of the wound without removal. These dressings are often used in combination with other treatments to optimize healing. Antibiotic ointments, on the other hand, are applied to prevent or treat infections in the wound. They are particularly important in cases where the risk of infection is high or when an infection is already present. Commonly used antibiotic ointments include those containing bacitracin, neomycin, and polymyxin B. These ointments work by killing or inhibiting the growth of bacteria, thereby reducing the risk of complications and promoting faster healing. In addition to traditional antibiotic ointments, there is a growing interest in advanced formulations that incorporate antimicrobial agents such as silver or honey, which have natural antibacterial properties. The choice of dressing and antibiotic ointment depends on various factors, including the stage of the bedsore, the level of exudate, the presence of infection, and the patient's overall health condition. Healthcare professionals play a vital role in assessing these factors and recommending the most appropriate treatment plan. The integration of dressing and antibiotic ointments into a comprehensive care regimen is essential for effective bedsore management. This often involves regular monitoring and reassessment of the wound, as well as adjustments to the treatment plan as needed. The Global Bedsore Medicine Market continues to evolve with advancements in dressing materials and antibiotic formulations, offering new possibilities for improved patient outcomes. As research and development efforts continue, the market is expected to see the introduction of innovative products that enhance the efficacy and convenience of bedsore treatment. The focus on patient-centered care and the growing emphasis on preventing hospital-acquired pressure ulcers are driving the demand for effective dressing and antibiotic ointment solutions. This trend underscores the importance of ongoing education and training for healthcare providers to ensure the optimal use of these products in clinical practice.

Hospital, Clinic, Pharmacy, Online in the Global Bedsore Medicine Market:

The usage of Global Bedsore Medicine Market products varies across different healthcare settings, including hospitals, clinics, pharmacies, and online platforms. In hospitals, bedsore management is a critical aspect of patient care, particularly for those who are bedridden or have limited mobility. Hospitals often have dedicated wound care teams that assess and treat pressure ulcers using a combination of dressings, antibiotic ointments, and advanced therapies. The availability of a wide range of products allows healthcare professionals to tailor treatment plans to the specific needs of each patient, ensuring optimal outcomes. In clinics, bedsore treatment is often part of outpatient care for patients who require ongoing management of chronic wounds. Clinics may offer specialized wound care services, providing patients with access to the latest treatments and technologies. The use of dressings and antibiotic ointments in clinics is guided by evidence-based protocols and best practices, ensuring that patients receive high-quality care. Pharmacies play a crucial role in the distribution of bedsore medicine products, providing patients and caregivers with access to over-the-counter and prescription treatments. Pharmacists are often involved in educating patients about the proper use of dressings and ointments, as well as advising on wound care management. The availability of a wide range of products in pharmacies ensures that patients can find the most suitable options for their needs. Online platforms have emerged as a convenient option for purchasing bedsore medicine products, offering a wide selection of dressings, ointments, and other wound care supplies. The growth of e-commerce has made it easier for patients and caregivers to access products from the comfort of their homes, with the added benefit of home delivery. Online platforms often provide detailed product information and customer reviews, helping consumers make informed decisions. The usage of Global Bedsore Medicine Market products across these settings highlights the importance of accessibility and convenience in wound care management. As the market continues to evolve, the integration of digital technologies and telemedicine is expected to enhance the delivery of bedsore treatment, improving patient outcomes and satisfaction. The focus on patient-centered care and the growing emphasis on preventing hospital-acquired pressure ulcers are driving the demand for effective dressing and antibiotic ointment solutions. This trend underscores the importance of ongoing education and training for healthcare providers to ensure the optimal use of these products in clinical practice.

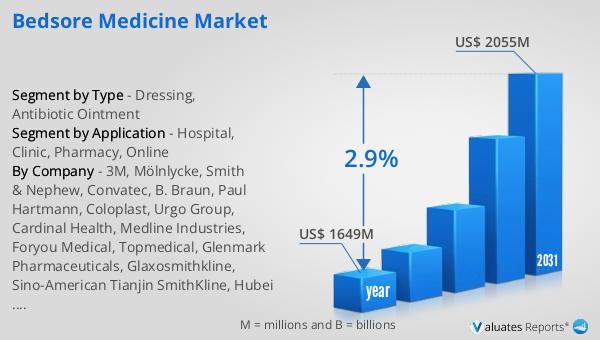

Global Bedsore Medicine Market Outlook:

The worldwide market for Bedsore Medicine was estimated to be worth $1,649 million in 2024, and it is anticipated to expand to a revised valuation of $2,055 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% throughout the forecast period. This growth trajectory underscores the increasing demand for effective bedsore management solutions as the global population ages and the prevalence of pressure ulcers rises. The market's expansion is driven by several factors, including advancements in medical technology, increased awareness of patient care standards, and the growing emphasis on preventing hospital-acquired pressure ulcers. As healthcare providers and caregivers seek innovative products to manage and prevent bedsores, the market is poised for continued growth. The projected increase in market size reflects the ongoing research and development efforts aimed at improving treatment outcomes and enhancing patient quality of life. The focus on patient-centered care and the integration of digital technologies and telemedicine are expected to further drive the demand for bedsore medicine products. As the market evolves, the introduction of new and advanced products will play a crucial role in meeting the needs of patients and healthcare providers, ensuring effective bedsore management and improved patient outcomes.

| Report Metric | Details |

| Report Name | Bedsore Medicine Market |

| Accounted market size in year | US$ 1649 million |

| Forecasted market size in 2031 | US$ 2055 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | 3M, Mölnlycke, Smith & Nephew, Convatec, B. Braun, Paul Hartmann, Coloplast, Urgo Group, Cardinal Health, Medline Industries, Foryou Medical, Topmedical, Glenmark Pharmaceuticals, Glaxosmithkline, Sino-American Tianjin SmithKline, Hubei Renfu Chengtian Pharmaceutical, Hangzhou Zhuyangxin Pharmaceutical, Padagis, Front Pharmaceutical, NIPRO JMI Pharma, Taro Pharmaceutical, Teva Pharmaceuticals, Prati-Donaduzzi, Unilab, Encube Ethicals, Bright Future Pharmaceutical, Hengjian Pharmaceutical, Square Pharmaceuticals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |