What is Global LNG Ultra-low Temperature Valve Market?

The Global LNG Ultra-low Temperature Valve Market is a specialized segment within the broader industrial valve market, focusing on valves that can operate efficiently under extremely low temperatures, typically associated with liquefied natural gas (LNG) applications. These valves are crucial in maintaining the integrity and safety of LNG systems, as they control the flow of cryogenic fluids, which are stored and transported at temperatures as low as -162 degrees Celsius. The market for these valves is driven by the increasing demand for LNG as a cleaner energy source, which necessitates robust infrastructure for its production, transportation, and storage. The valves used in this market must be made from materials that can withstand such low temperatures without becoming brittle or losing functionality. Additionally, they must ensure a tight seal to prevent leaks, which could lead to safety hazards or product loss. The market is characterized by a range of valve types, each serving specific functions within the LNG supply chain, and is influenced by technological advancements, regulatory standards, and the global push towards sustainable energy solutions. As the LNG industry continues to expand, the demand for ultra-low temperature valves is expected to grow, highlighting their critical role in the energy sector.

Throttle Valve, Globe Valve, Ball Valve, Check Valve, Butterfly Valve, Others in the Global LNG Ultra-low Temperature Valve Market:

Throttle valves, globe valves, ball valves, check valves, butterfly valves, and others play distinct roles in the Global LNG Ultra-low Temperature Valve Market, each designed to meet specific operational needs within LNG systems. Throttle valves are primarily used to control the flow rate of LNG by adjusting the valve opening, allowing precise regulation of fluid dynamics in the system. These valves are essential in applications where maintaining a specific flow rate is crucial to system performance and safety. Globe valves, known for their excellent throttling capabilities, are used to start, stop, and regulate the flow of LNG. Their design allows for precise control, making them ideal for applications where flow regulation is critical. Ball valves, with their simple design and quick operation, are used for on/off control without pressure drop. They are highly reliable and provide a tight seal, which is essential in preventing leaks in LNG systems. Check valves are used to prevent backflow in the system, ensuring that LNG flows in the desired direction. This is crucial in maintaining system integrity and preventing potential damage to equipment. Butterfly valves, known for their compact design and ease of operation, are used for isolating or regulating flow. They offer a quick shut-off and are suitable for large diameter pipes, making them ideal for LNG applications where space and weight are considerations. Other valves in this market include gate valves and plug valves, each serving specific functions within the LNG supply chain. Gate valves are used for on/off control and are not suitable for throttling applications, while plug valves offer a simple design for quick operation. The choice of valve type depends on various factors, including the specific application, flow requirements, and system design. Each valve type must be constructed from materials that can withstand ultra-low temperatures and provide reliable performance in cryogenic conditions. The market for these valves is driven by the need for efficient and safe LNG systems, with manufacturers focusing on innovation and quality to meet the demands of the industry. As the LNG industry continues to grow, the demand for these specialized valves is expected to increase, highlighting their importance in the global energy landscape.

LNG Production Plant, LNG Transport Equipment, LNG Receiving Station, LNG Gasification Station, Others in the Global LNG Ultra-low Temperature Valve Market:

The usage of Global LNG Ultra-low Temperature Valve Market in various areas such as LNG production plants, LNG transport equipment, LNG receiving stations, LNG gasification stations, and others is crucial for the efficient and safe handling of LNG. In LNG production plants, these valves are used to control the flow of natural gas during the liquefaction process, where natural gas is cooled to its liquid state. The valves must ensure precise control and tight sealing to prevent leaks and maintain the integrity of the system. In LNG transport equipment, such as LNG carriers, these valves are essential for managing the flow of LNG during loading and unloading operations. They must be able to withstand the harsh conditions of marine environments while providing reliable performance. In LNG receiving stations, ultra-low temperature valves are used to control the flow of LNG as it is transferred from carriers to storage tanks. These valves play a critical role in ensuring the safe and efficient transfer of LNG, preventing leaks and maintaining system integrity. In LNG gasification stations, where LNG is converted back to its gaseous state, these valves are used to regulate the flow of LNG and ensure precise control during the gasification process. Other applications of these valves include LNG fueling stations and industrial applications where LNG is used as a fuel source. In all these areas, the valves must be constructed from materials that can withstand ultra-low temperatures and provide reliable performance in cryogenic conditions. The demand for these valves is driven by the increasing use of LNG as a cleaner energy source, necessitating robust infrastructure for its production, transportation, and storage. As the LNG industry continues to expand, the demand for ultra-low temperature valves is expected to grow, highlighting their critical role in the energy sector.

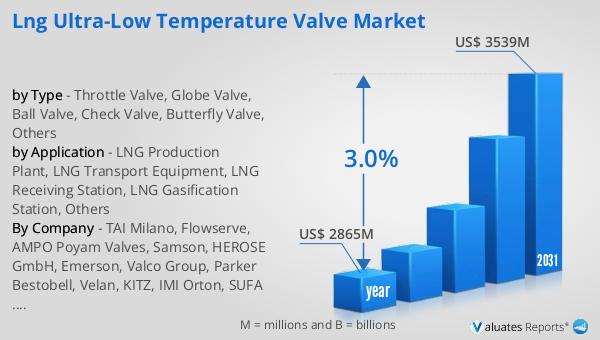

Global LNG Ultra-low Temperature Valve Market Outlook:

The global market for LNG Ultra-low Temperature Valves was valued at approximately $2,865 million in 2024. It is anticipated to grow to a revised size of around $3,539 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.0% over the forecast period. This growth is indicative of the increasing demand for LNG as a cleaner energy source, which in turn drives the need for specialized valves capable of operating under ultra-low temperature conditions. These valves are essential components in the LNG supply chain, ensuring the safe and efficient handling of LNG from production to end-use. The market's expansion is supported by technological advancements in valve design and materials, which enhance their performance and reliability in cryogenic applications. Additionally, the global push towards sustainable energy solutions and the need for robust infrastructure to support LNG operations contribute to the market's growth. As the LNG industry continues to evolve, the demand for ultra-low temperature valves is expected to increase, underscoring their importance in the global energy landscape. The market outlook reflects the critical role these valves play in ensuring the safety and efficiency of LNG systems, highlighting their significance in the transition towards cleaner energy sources.

| Report Metric | Details |

| Report Name | LNG Ultra-low Temperature Valve Market |

| Accounted market size in year | US$ 2865 million |

| Forecasted market size in 2031 | US$ 3539 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TAI Milano, Flowserve, AMPO Poyam Valves, Samson, HEROSE GmbH, Emerson, Valco Group, Parker Bestobell, Velan, KITZ, IMI Orton, SUFA Technology Industry, Wenzhou Zhengmao Valve, Zhejiang Liangjing Valve, Jiangsu Shentong Valve, Shanghai Hudong Marine Valve Manufacturer, Zhejiang Saifu Valve, Zhejiang Baoyi Group, Wenzhou Fangzheng Valve Group, JIANGSU YDF VALVE, Suzhou Neway Valve, NAVC (Shanghai) Valve Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |