What is Global Stainless Steel Ultra-Thin Vapor Chamber Market?

The Global Stainless Steel Ultra-Thin Vapor Chamber Market is a specialized segment within the broader thermal management industry, focusing on the development and application of ultra-thin vapor chambers made from stainless steel. These vapor chambers are critical components used to dissipate heat in electronic devices, ensuring they operate efficiently and reliably. Unlike traditional heat sinks, these chambers utilize the phase change of a working fluid to transfer heat, making them highly effective in managing thermal loads in compact spaces. The use of stainless steel provides durability and resistance to corrosion, which is essential for maintaining performance over time. This market is driven by the increasing demand for high-performance electronic devices that require efficient thermal management solutions. As devices become more compact and powerful, the need for advanced cooling technologies like ultra-thin vapor chambers becomes more pronounced. The market is characterized by continuous innovation, with manufacturers striving to develop thinner, more efficient chambers to meet the evolving needs of the electronics industry. This growth is further fueled by the expansion of industries such as consumer electronics, telecommunications, and computing, where thermal management is a critical concern.

Less Than 0.3 mm, 0.3-0.5 mm in the Global Stainless Steel Ultra-Thin Vapor Chamber Market:

The Global Stainless Steel Ultra-Thin Vapor Chamber Market is segmented based on thickness, with two primary categories: less than 0.3 mm and 0.3-0.5 mm. These categories are crucial as they determine the application and performance of the vapor chambers in various devices. Vapor chambers with a thickness of less than 0.3 mm are particularly significant in applications where space is at a premium, such as in smartphones and ultra-thin laptops. These chambers are designed to provide efficient heat dissipation without adding significant bulk to the device. The challenge in manufacturing these ultra-thin chambers lies in maintaining structural integrity and performance while reducing thickness. Advanced manufacturing techniques and materials are employed to achieve the desired specifications, ensuring that the chambers can withstand the thermal and mechanical stresses encountered in everyday use. On the other hand, vapor chambers with a thickness of 0.3-0.5 mm offer a balance between performance and manufacturability. These chambers are often used in devices where space constraints are less stringent, but efficient thermal management is still required. The slightly thicker design allows for greater flexibility in terms of the working fluid and wick structure, which can enhance the overall thermal performance. This category is particularly relevant for applications in tablets, gaming consoles, and other consumer electronics where heat dissipation is critical to maintaining performance and user comfort. The choice between these two thickness categories depends on the specific requirements of the application, including the available space, thermal load, and desired performance characteristics. Manufacturers must carefully consider these factors when designing and selecting vapor chambers for their products. The ongoing trend towards miniaturization and increased performance in electronic devices continues to drive innovation in this market, with companies investing in research and development to create thinner, more efficient vapor chambers. This focus on innovation is essential to meet the growing demand for high-performance thermal management solutions in an increasingly competitive market. As the industry evolves, the ability to produce ultra-thin vapor chambers that deliver exceptional performance will be a key differentiator for manufacturers.

Smartphone, Tablet in the Global Stainless Steel Ultra-Thin Vapor Chamber Market:

The usage of Global Stainless Steel Ultra-Thin Vapor Chambers in smartphones and tablets is a testament to the critical role these components play in modern electronics. In smartphones, the demand for high-performance devices with sleek designs has led to the adoption of ultra-thin vapor chambers as a preferred thermal management solution. These chambers are integrated into the phone's design to efficiently dissipate heat generated by the processor, battery, and other components. By maintaining optimal operating temperatures, vapor chambers help prevent overheating, which can lead to performance throttling and reduced battery life. The use of stainless steel ensures that the chambers are durable and resistant to corrosion, which is essential for maintaining performance over the device's lifespan. In tablets, the need for effective thermal management is equally important, as these devices often run resource-intensive applications that generate significant heat. Ultra-thin vapor chambers are used to distribute heat evenly across the device, preventing hot spots and ensuring a comfortable user experience. The ability to maintain consistent performance without compromising on design is a key advantage of using vapor chambers in tablets. As tablets become more powerful and versatile, the demand for efficient thermal management solutions continues to grow. The integration of ultra-thin vapor chambers in these devices allows manufacturers to meet consumer expectations for performance and reliability. Overall, the use of stainless steel ultra-thin vapor chambers in smartphones and tablets highlights the importance of advanced thermal management solutions in the electronics industry. As devices become more compact and powerful, the need for efficient cooling technologies will continue to drive innovation and growth in this market.

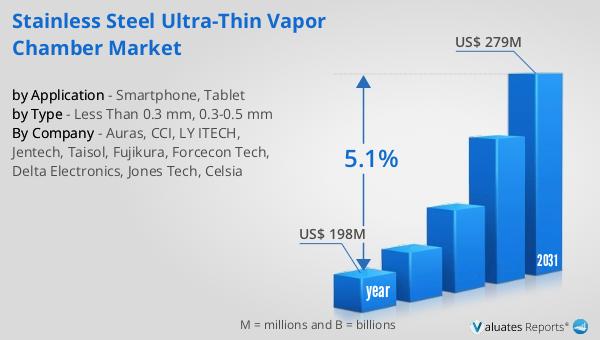

Global Stainless Steel Ultra-Thin Vapor Chamber Market Outlook:

The outlook for the Global Stainless Steel Ultra-Thin Vapor Chamber Market is promising, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 198 million, reflecting the increasing demand for advanced thermal management solutions in various industries. By 2031, the market is projected to reach a revised size of US$ 279 million, growing at a compound annual growth rate (CAGR) of 5.1% during the forecast period. This growth is driven by the expanding consumer electronics sector, where the need for efficient heat dissipation solutions is paramount. As electronic devices become more powerful and compact, the demand for ultra-thin vapor chambers is expected to rise, as they offer an effective solution for managing thermal loads in limited spaces. The market's growth is also supported by advancements in manufacturing technologies, which enable the production of thinner and more efficient vapor chambers. Companies are investing in research and development to enhance the performance and reliability of these components, ensuring they meet the evolving needs of the electronics industry. The increasing adoption of stainless steel ultra-thin vapor chambers in smartphones, tablets, and other consumer electronics is a key factor contributing to the market's expansion. As the industry continues to innovate and evolve, the demand for high-performance thermal management solutions is expected to drive further growth in the Global Stainless Steel Ultra-Thin Vapor Chamber Market.

| Report Metric | Details |

| Report Name | Stainless Steel Ultra-Thin Vapor Chamber Market |

| Accounted market size in year | US$ 198 million |

| Forecasted market size in 2031 | US$ 279 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Auras, CCI, LY ITECH, Jentech, Taisol, Fujikura, Forcecon Tech, Delta Electronics, Jones Tech, Celsia |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |