What is Global Liquid Egg Processing Machine Market?

The Global Liquid Egg Processing Machine Market is a specialized segment within the food processing industry that focuses on the machinery used to process liquid eggs. These machines are essential for converting raw eggs into liquid form, which is then used in various food products and culinary applications. The market encompasses a range of equipment designed to handle different stages of egg processing, including washing, breaking, separating, and pasteurizing. The demand for liquid egg processing machines is driven by the growing consumption of processed egg products, which are favored for their convenience and extended shelf life. These machines are crucial for ensuring the safety, quality, and efficiency of egg processing, meeting the stringent hygiene standards required in food production. As the global population continues to rise and dietary preferences evolve, the need for efficient and reliable egg processing solutions is expected to grow, making this market an important component of the broader food processing industry. The market is characterized by technological advancements aimed at improving processing speed, reducing waste, and enhancing product quality, thereby catering to the diverse needs of small, medium, and large-scale egg processing facilities worldwide.

Egg Washing Machine, Egg Breakers & Separators, Others in the Global Liquid Egg Processing Machine Market:

In the Global Liquid Egg Processing Machine Market, several key types of machinery play pivotal roles, including Egg Washing Machines, Egg Breakers & Separators, and other specialized equipment. Egg Washing Machines are designed to clean eggs thoroughly before they are processed further. This step is crucial as it removes dirt, bacteria, and other contaminants from the eggshells, ensuring that the eggs are safe for consumption and further processing. These machines use a combination of water, detergents, and brushes to clean the eggs efficiently, and they are often equipped with features that allow for the adjustment of washing intensity based on the condition of the eggs. Egg Breakers & Separators are another critical component of the liquid egg processing line. These machines are responsible for breaking the eggs and separating the yolks from the whites. This process is essential for producing different types of liquid egg products, such as liquid egg whites, yolks, or whole eggs. The machines are designed to handle large volumes of eggs with precision, minimizing waste and ensuring that the separation process is as efficient as possible. Advanced models are equipped with sensors and automated systems that enhance accuracy and reduce the need for manual intervention. Other equipment in the liquid egg processing market includes pasteurizers, homogenizers, and packaging machines. Pasteurizers are used to heat-treat the liquid eggs, killing any harmful bacteria and extending the product's shelf life. This step is vital for ensuring the safety and quality of the final product. Homogenizers are employed to create a uniform mixture of egg components, which is particularly important for certain applications where consistency is key. Packaging machines are used to fill and seal the processed liquid eggs into containers, ready for distribution. These machines are designed to maintain the integrity of the product while ensuring that it is packaged efficiently and hygienically. The integration of these machines into a cohesive processing line is essential for optimizing production efficiency and meeting the demands of various markets. As technology continues to advance, the capabilities of these machines are expected to improve, offering greater precision, speed, and energy efficiency. This evolution is driven by the need to meet the growing demand for processed egg products while adhering to strict food safety regulations and sustainability goals.

Small and Medium Liquid Egg Factory, Big Liquid Egg Factory in the Global Liquid Egg Processing Machine Market:

The usage of Global Liquid Egg Processing Machines varies significantly between small and medium liquid egg factories and large-scale operations. In small and medium liquid egg factories, the focus is often on flexibility and cost-effectiveness. These facilities typically cater to local or regional markets, producing a range of liquid egg products to meet specific customer needs. The machinery used in these factories is often modular, allowing for easy adaptation to different production requirements. This flexibility is crucial for smaller operations that may need to switch between different product lines or adjust production volumes based on demand. The machines in these factories are designed to be user-friendly, with straightforward controls and maintenance procedures, enabling operators to manage the equipment efficiently without extensive technical expertise. In contrast, large liquid egg factories operate on a much larger scale, often supplying national or international markets. These facilities require high-capacity machines capable of processing vast quantities of eggs quickly and efficiently. The focus here is on maximizing throughput while maintaining product quality and safety. Advanced automation and integration are key features of the machinery used in these factories, allowing for seamless operation and minimal downtime. The machines are equipped with sophisticated control systems that enable precise monitoring and adjustment of processing parameters, ensuring consistent product quality. Additionally, large-scale operations often invest in state-of-the-art technology to enhance energy efficiency and reduce waste, aligning with sustainability goals and regulatory requirements. Both small and large liquid egg factories benefit from the advancements in liquid egg processing technology, which offer improved efficiency, safety, and product quality. However, the scale and scope of their operations dictate the specific machinery and features they prioritize. As the demand for liquid egg products continues to grow, driven by factors such as convenience, health trends, and global population growth, both small and large factories are likely to invest in advanced processing solutions to meet market needs. This investment not only enhances their production capabilities but also ensures compliance with stringent food safety standards, ultimately contributing to the overall growth and development of the Global Liquid Egg Processing Machine Market.

Global Liquid Egg Processing Machine Market Outlook:

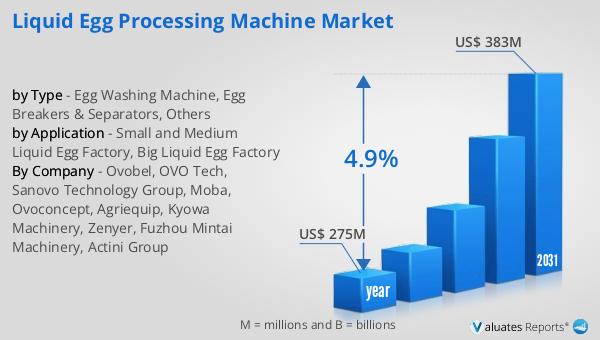

The global market for Liquid Egg Processing Machines was valued at approximately $275 million in 2024. It is anticipated to expand to a revised size of around $383 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.9% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable egg processing solutions across the globe. The market's expansion is driven by several factors, including the rising consumption of processed egg products, which are favored for their convenience and extended shelf life. Additionally, technological advancements in egg processing machinery are enhancing the efficiency, safety, and quality of egg products, further fueling market growth. As dietary preferences evolve and the global population continues to rise, the need for advanced egg processing solutions is expected to grow, making this market an important component of the broader food processing industry. The projected growth of the market highlights the ongoing investment in research and development aimed at improving processing speed, reducing waste, and enhancing product quality. This investment is crucial for meeting the diverse needs of small, medium, and large-scale egg processing facilities worldwide, ensuring that they can continue to deliver high-quality products to consumers.

| Report Metric | Details |

| Report Name | Liquid Egg Processing Machine Market |

| Accounted market size in year | US$ 275 million |

| Forecasted market size in 2031 | US$ 383 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ovobel, OVO Tech, Sanovo Technology Group, Moba, Ovoconcept, Agriequip, Kyowa Machinery, Zenyer, Fuzhou Mintai Machinery, Actini Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |