What is Commutator For Power Tool - Global Market?

Commutators are essential components in power tools, playing a crucial role in the operation of electric motors. They are responsible for reversing the direction of current flow through the motor windings, which is necessary for the continuous rotation of the motor shaft. This process allows power tools to function efficiently and effectively. The global market for commutators in power tools is a dynamic and evolving sector, driven by the increasing demand for power tools across various industries, including construction, automotive, and home improvement. As technology advances, the design and efficiency of commutators are also improving, leading to enhanced performance and durability of power tools. The market is characterized by a diverse range of products, catering to different types of power tools and applications. Manufacturers are focusing on developing commutators that offer better conductivity, reduced wear and tear, and longer service life. This market is also influenced by the growing trend towards cordless power tools, which require more efficient and reliable commutators to ensure optimal performance. Overall, the commutator for power tool market is poised for growth, driven by technological advancements and increasing demand for high-performance power tools.

Groove Commutator, Hook Type Commutator in the Commutator For Power Tool - Global Market:

Groove commutators and hook type commutators are two prevalent types of commutators used in power tools, each with distinct characteristics and applications. Groove commutators are designed with grooves on their surface, which help in maintaining the alignment of the brushes and ensuring consistent contact with the commutator surface. This design minimizes the risk of sparking and enhances the overall efficiency of the motor. Groove commutators are commonly used in power tools that require high precision and reliability, such as electric drills and grinders. They are favored for their ability to withstand high rotational speeds and heavy-duty operations, making them ideal for industrial applications. On the other hand, hook type commutators feature hooks or slots that secure the winding wires in place. This design provides a robust connection between the commutator and the windings, ensuring stable electrical performance. Hook type commutators are often used in power tools that demand high torque and power output, such as impact wrenches and chainsaws. They are known for their durability and ability to handle high current loads, making them suitable for demanding tasks. Both groove and hook type commutators are integral to the performance of power tools, and their selection depends on the specific requirements of the application. Manufacturers are continuously innovating to improve the design and materials used in these commutators, aiming to enhance their efficiency, reliability, and lifespan. The global market for these commutators is driven by the increasing demand for power tools in various sectors, including construction, automotive, and home improvement. As power tools become more advanced and versatile, the need for high-quality commutators that can support their performance is also growing. This has led to a competitive market landscape, with manufacturers striving to offer products that meet the evolving needs of consumers. The development of new materials and manufacturing techniques is also contributing to the growth of the commutator market, as these innovations enable the production of commutators that are more efficient and durable. Overall, the groove and hook type commutator market is poised for growth, driven by technological advancements and increasing demand for high-performance power tools.

Electric drill, Impact wrench, Electric grinder, chainsaw, Sanding machine, Other in the Commutator For Power Tool - Global Market:

Commutators are vital components in various power tools, enabling them to perform efficiently and effectively. In electric drills, commutators play a crucial role in converting electrical energy into mechanical energy, allowing the drill to rotate and perform tasks such as drilling holes and driving screws. The commutator ensures that the motor operates smoothly and consistently, providing the necessary torque and speed for different applications. In impact wrenches, commutators are responsible for delivering high torque output, which is essential for loosening and tightening bolts and nuts. The commutator's design and material are critical in ensuring that the impact wrench can handle the high current loads and provide the necessary power for demanding tasks. Electric grinders rely on commutators to maintain a consistent rotational speed, allowing them to perform tasks such as grinding, cutting, and polishing with precision and efficiency. The commutator's ability to withstand high rotational speeds and heavy-duty operations is crucial for the performance of electric grinders. Chainsaws, which are used for cutting wood and other materials, require commutators that can deliver high power output and withstand the rigors of outdoor use. The commutator's design and construction are essential in ensuring that the chainsaw can operate reliably and efficiently in various conditions. Sanding machines, used for smoothing surfaces and removing material, rely on commutators to provide the necessary speed and power for different sanding applications. The commutator's ability to maintain consistent contact with the brushes and minimize sparking is crucial for the performance of sanding machines. Other power tools, such as saws and polishers, also depend on commutators to convert electrical energy into mechanical energy and deliver the necessary power and speed for various tasks. The global market for commutators in power tools is driven by the increasing demand for these tools in various industries, including construction, automotive, and home improvement. As power tools become more advanced and versatile, the need for high-quality commutators that can support their performance is also growing. Manufacturers are focusing on developing commutators that offer better conductivity, reduced wear and tear, and longer service life. The development of new materials and manufacturing techniques is also contributing to the growth of the commutator market, as these innovations enable the production of commutators that are more efficient and durable. Overall, the commutator for power tool market is poised for growth, driven by technological advancements and increasing demand for high-performance power tools.

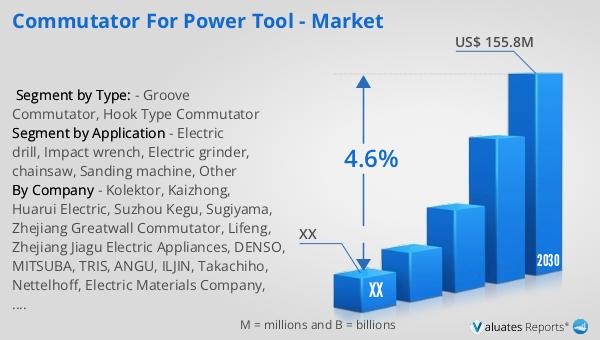

Commutator For Power Tool - Global Market Outlook:

The global market for commutators used in power tools was valued at approximately $114.2 million in 2023. It is anticipated to grow to a revised size of around $155.8 million by the year 2030, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for power tools across various sectors, which in turn drives the need for efficient and reliable commutators. In North America, the market for commutators in power tools was valued at a significant amount in 2023, with expectations of reaching an even higher value by 2030. The growth in this region is supported by technological advancements and the rising adoption of power tools in industries such as construction and automotive. The market dynamics in North America are characterized by a focus on innovation and the development of high-performance commutators that meet the evolving needs of consumers. As the demand for power tools continues to rise, the market for commutators is expected to expand, driven by the need for components that enhance the efficiency and durability of these tools. Overall, the global and North American markets for commutators in power tools are poised for growth, supported by technological advancements and increasing demand for high-performance power tools.

| Report Metric | Details |

| Report Name | Commutator For Power Tool - Market |

| Forecasted market size in 2030 | US$ 155.8 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kolektor, Kaizhong, Huarui Electric, Suzhou Kegu, Sugiyama, Zhejiang Greatwall Commutator, Lifeng, Zhejiang Jiagu Electric Appliances, DENSO, MITSUBA, TRIS, ANGU, ILJIN, Takachiho, Nettelhoff, Electric Materials Company, Bhagyanagar India Ltd, Toledo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |