What is Global High Pressure Injection Ceramic Market?

The Global High Pressure Injection Ceramic Market refers to the industry that deals with the production and distribution of ceramics that are manufactured using high-pressure injection molding techniques. These ceramics are known for their exceptional strength, durability, and resistance to wear and corrosion, making them ideal for a wide range of applications. The market encompasses various types of ceramics, including alumina, yttria-stabilized zirconia (YTZP), and zirconia toughened alumina (ZTA), among others. These materials are used in industries such as electronics, medical, aerospace, and more, due to their superior mechanical properties and ability to withstand extreme conditions. The market is driven by the increasing demand for high-performance materials in advanced applications, as well as ongoing advancements in ceramic manufacturing technologies. As industries continue to seek materials that offer enhanced performance and longevity, the Global High Pressure Injection Ceramic Market is expected to grow, providing innovative solutions to meet these needs.

Alumina, Yttria-Stabilized Zirconia (YTZP), Zirconia Toughened Alumina (ZTA), Others in the Global High Pressure Injection Ceramic Market:

Alumina, yttria-stabilized zirconia (YTZP), zirconia toughened alumina (ZTA), and other ceramics play a crucial role in the Global High Pressure Injection Ceramic Market. Alumina, also known as aluminum oxide, is one of the most widely used ceramics due to its excellent hardness, high melting point, and resistance to chemical attack. It is commonly used in applications that require wear resistance and thermal stability, such as cutting tools, electrical insulators, and biomedical implants. Yttria-stabilized zirconia (YTZP) is another important ceramic material known for its high fracture toughness and resistance to crack propagation. This makes it ideal for applications that require high strength and durability, such as dental implants, fuel cell components, and cutting tools. Zirconia toughened alumina (ZTA) combines the properties of both alumina and zirconia, offering enhanced toughness and strength. This material is used in applications where both wear resistance and mechanical strength are critical, such as in the manufacturing of bearings, seals, and pump components. Other ceramics in the market include silicon carbide, silicon nitride, and various composites, each offering unique properties that cater to specific industrial needs. The versatility and performance of these materials make them indispensable in the development of advanced technologies and products.

Electronic Appliances, Medical Industry, Aerospace, Others in the Global High Pressure Injection Ceramic Market:

The Global High Pressure Injection Ceramic Market finds extensive usage in various sectors, including electronic appliances, the medical industry, aerospace, and others. In the realm of electronic appliances, high-pressure injection ceramics are used to manufacture components that require high precision, thermal stability, and electrical insulation. These ceramics are essential in the production of semiconductors, capacitors, and other electronic devices that operate under high temperatures and harsh conditions. In the medical industry, high-pressure injection ceramics are utilized to create biocompatible implants, dental prosthetics, and surgical instruments. Their exceptional strength, wear resistance, and compatibility with biological tissues make them ideal for medical applications that demand reliability and longevity. The aerospace industry also benefits significantly from high-pressure injection ceramics, as these materials are used to produce components that can withstand extreme temperatures, pressures, and mechanical stresses. Ceramics are employed in the manufacturing of turbine blades, heat shields, and structural components, contributing to the overall performance and safety of aerospace systems. Additionally, high-pressure injection ceramics are used in other industries such as automotive, defense, and energy, where their unique properties enable the development of innovative solutions for challenging environments. The widespread adoption of these ceramics across various sectors underscores their importance in advancing technology and improving the performance of critical applications.

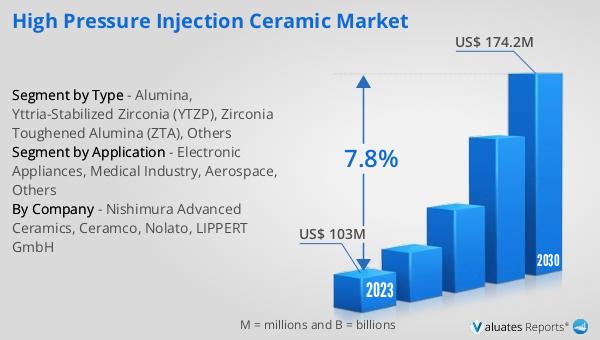

Global High Pressure Injection Ceramic Market Outlook:

The global High Pressure Injection Ceramic market was valued at US$ 103 million in 2023 and is anticipated to reach US$ 174.2 million by 2030, witnessing a compound annual growth rate (CAGR) of 7.8% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-performance ceramic materials across various industries. The market's expansion is driven by the need for materials that offer superior mechanical properties, durability, and resistance to extreme conditions. As industries such as electronics, medical, aerospace, and others continue to evolve and require advanced materials for their applications, the demand for high-pressure injection ceramics is expected to rise. The market's growth trajectory indicates a promising future for the development and adoption of these innovative materials, which are essential for enhancing the performance and longevity of products in demanding environments.

| Report Metric | Details |

| Report Name | High Pressure Injection Ceramic Market |

| Accounted market size in 2023 | US$ 103 million |

| Forecasted market size in 2030 | US$ 174.2 million |

| CAGR | 7.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nishimura Advanced Ceramics, Ceramco, Nolato, LIPPERT GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |