What is Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market?

The Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market is a specialized segment within the broader hydrogen economy, focusing on the development and deployment of filters designed to withstand high-pressure environments. These filters are crucial components in hydrogen storage systems, ensuring the purity and safety of hydrogen gas as it is stored and transported. Hydrogen, being the lightest and most abundant element, is increasingly being used as a clean energy source. However, its storage and transportation pose significant challenges due to its high diffusivity and reactivity. High-pressure hydrogen filters are engineered to address these challenges by maintaining the integrity of hydrogen storage tanks, preventing contamination, and ensuring that only pure hydrogen is delivered for use. These filters are typically made from advanced materials capable of withstanding extreme pressures and temperatures, making them indispensable in applications ranging from hydrogen refueling stations to onboard hydrogen storage systems in vehicles. As the world shifts towards cleaner energy solutions, the demand for efficient and reliable hydrogen storage solutions, including high-pressure filters, is expected to grow, driving innovation and investment in this market segment.

350-700 bar, >700 bar in the Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market:

The Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market is segmented based on pressure ratings, primarily into two categories: 350-700 bar and greater than 700 bar. The 350-700 bar segment is significant as it represents the standard pressure range for many hydrogen storage applications, including those used in hydrogen refueling stations and onboard storage systems for fuel cell vehicles. Filters designed for this pressure range are engineered to ensure the safe and efficient storage of hydrogen, preventing leaks and contamination while maintaining the purity of the gas. These filters are typically constructed from robust materials such as stainless steel or advanced composites, capable of withstanding the high pressures and potential corrosive effects of hydrogen. The greater than 700 bar segment, on the other hand, represents the cutting-edge of hydrogen storage technology. As the demand for higher storage capacities and longer driving ranges for hydrogen-powered vehicles increases, the need for storage solutions that can handle pressures exceeding 700 bar becomes more critical. Filters in this category are designed to meet the stringent safety and performance requirements of these high-pressure systems, often incorporating advanced materials and innovative designs to ensure reliability and efficiency. The development of filters for pressures greater than 700 bar is driven by the need to optimize hydrogen storage systems, enabling them to store more hydrogen in a given volume, thereby enhancing the overall efficiency and practicality of hydrogen as an energy carrier. This segment is particularly important for applications where space and weight are at a premium, such as in aerospace or high-performance automotive applications. As the hydrogen economy continues to evolve, the demand for high-pressure hydrogen filters across both pressure segments is expected to grow, driven by the increasing adoption of hydrogen as a clean energy source and the ongoing development of new and improved hydrogen storage technologies. The market for these filters is characterized by a high degree of innovation, with manufacturers continually seeking to improve the performance, durability, and cost-effectiveness of their products to meet the evolving needs of the hydrogen industry.

Hydrogen Refueling Station Hydrogen Storage System, On-board Hydrogen Storage Cylinder in the Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market:

High-pressure hydrogen filters play a crucial role in various applications within the hydrogen economy, particularly in hydrogen refueling stations, hydrogen storage systems, and onboard hydrogen storage cylinders. In hydrogen refueling stations, these filters are essential for ensuring the purity and safety of the hydrogen gas being dispensed. As hydrogen is stored and transported at high pressures, there is a risk of contamination from particulates or other impurities that could compromise the performance of fuel cells or other hydrogen-powered systems. High-pressure filters are designed to remove these contaminants, ensuring that only pure hydrogen is delivered to vehicles or other end-use applications. This is critical for maintaining the efficiency and longevity of fuel cell systems, as even small amounts of impurities can cause significant damage over time. In hydrogen storage systems, high-pressure filters are used to maintain the integrity of the storage tanks, preventing leaks and ensuring that the hydrogen remains pure and uncontaminated. These filters are typically installed at various points within the storage system, including at the inlet and outlet of the storage tanks, to provide multiple layers of protection against contamination. This is particularly important in large-scale storage applications, where the potential for contamination is higher due to the larger volumes of hydrogen being stored. Onboard hydrogen storage cylinders, used in hydrogen-powered vehicles, also rely on high-pressure filters to ensure the purity and safety of the hydrogen gas being used. These filters are designed to withstand the high pressures and temperatures associated with onboard storage, providing a critical layer of protection against contamination and ensuring that the hydrogen fuel remains pure and effective. As the hydrogen economy continues to grow, the demand for high-pressure hydrogen filters in these and other applications is expected to increase, driving innovation and investment in this important market segment.

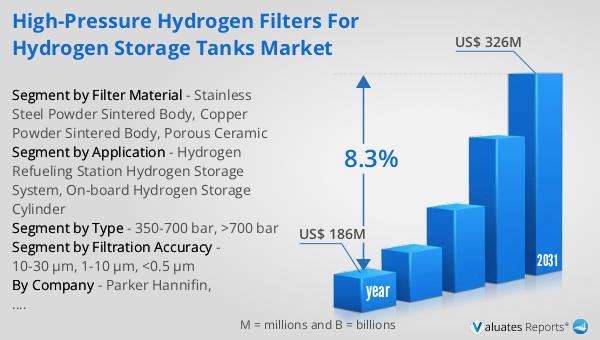

Global High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market Outlook:

The global market for high-pressure hydrogen filters designed for hydrogen storage tanks was valued at approximately $186 million in 2024. This market is anticipated to expand significantly, reaching an estimated value of $326 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.3% over the forecast period. This upward trend is indicative of the increasing demand for efficient and reliable hydrogen storage solutions as the world transitions towards cleaner energy sources. The market's expansion is driven by the growing adoption of hydrogen as a sustainable energy carrier, necessitating advanced storage technologies that can ensure the safety and purity of hydrogen gas. High-pressure hydrogen filters are critical components in this context, as they help maintain the integrity of storage systems by preventing contamination and ensuring that only pure hydrogen is delivered for use. As industries and governments worldwide continue to invest in hydrogen infrastructure and technology, the demand for high-quality hydrogen filters is expected to rise, further fueling market growth. This market outlook underscores the importance of innovation and development in the field of hydrogen storage, as companies strive to meet the evolving needs of the hydrogen economy.

| Report Metric | Details |

| Report Name | High-Pressure Hydrogen Filters for Hydrogen Storage Tanks Market |

| Accounted market size in year | US$ 186 million |

| Forecasted market size in 2031 | US$ 326 million |

| CAGR | 8.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Filtration Accuracy |

|

| Segment by Filter Material |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, Hydac, Pall Corporation, Walker Filtration, Classic Filters, Norman Filters, Fujikin Incorporated, Donalson, WEH GmbH, Maximator GmbH, cmc Instruments GmbH, Chase Filters & Components, EV Hydrogen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |