What is Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market?

The Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market is a specialized segment within the broader hydrogen energy industry. These filters are crucial components in hydrogen refueling stations, which are facilities designed to refuel hydrogen-powered vehicles. The primary function of these filters is to ensure the purity and safety of hydrogen gas as it is transferred from storage tanks to vehicles. High-pressure hydrogen filters are engineered to withstand the extreme pressures involved in hydrogen refueling, which can exceed 700 bar. They are designed to remove impurities and particulates that could potentially damage fuel cells or other components in hydrogen-powered vehicles. As the world shifts towards cleaner energy solutions, the demand for hydrogen as a fuel source is increasing, leading to a growing need for efficient and reliable hydrogen refueling infrastructure. This market is driven by advancements in hydrogen technology, government policies promoting clean energy, and the increasing adoption of hydrogen fuel cell vehicles. The development of high-pressure hydrogen filters is essential for ensuring the safety, efficiency, and reliability of hydrogen refueling stations, making them a critical component in the transition to a hydrogen-based economy.

Normal Temperature Type, Wide Temperature Range Type, Low Temperature Type in the Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market:

In the Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market, there are different types of filters designed to operate under various temperature conditions: Normal Temperature Type, Wide Temperature Range Type, and Low Temperature Type. Each type is engineered to meet specific operational requirements and environmental conditions. The Normal Temperature Type filters are designed to function optimally at standard ambient temperatures. These filters are typically used in regions where the climate is moderate and does not experience extreme temperature fluctuations. They are constructed with materials that can withstand the pressures of hydrogen refueling while maintaining their integrity and performance at normal temperatures. The Wide Temperature Range Type filters are more versatile, capable of operating efficiently across a broader spectrum of temperatures. These filters are ideal for regions with significant temperature variations, such as areas that experience both hot summers and cold winters. They are built with advanced materials and technologies that allow them to maintain their performance and durability despite the changing environmental conditions. This adaptability makes them a popular choice for hydrogen refueling stations in diverse climates. The Low Temperature Type filters are specifically designed for use in extremely cold environments. These filters are constructed with materials that can withstand the challenges posed by low temperatures, such as brittleness and reduced flexibility. They ensure that hydrogen refueling stations can operate efficiently even in harsh winter conditions, providing reliable filtration and maintaining the purity of hydrogen gas. The development and deployment of these different types of high-pressure hydrogen filters are crucial for the global expansion of hydrogen refueling infrastructure. As hydrogen fuel cell vehicles become more prevalent, the demand for refueling stations equipped with reliable and efficient filters will continue to grow. Each type of filter plays a vital role in ensuring the safety and effectiveness of hydrogen refueling processes, contributing to the overall success of the hydrogen economy. By catering to various temperature conditions, these filters enable hydrogen refueling stations to operate in diverse environments, supporting the widespread adoption of hydrogen as a clean and sustainable energy source.

Compressor Front and Rear Ends, Hydrogen Dispenser Interior, Hydrogen Storage Tank Outlet in the Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market:

High-pressure hydrogen filters play a critical role in various components of hydrogen refueling stations, including the compressor front and rear ends, hydrogen dispenser interior, and hydrogen storage tank outlet. At the compressor front and rear ends, these filters are essential for maintaining the purity and quality of hydrogen gas as it is compressed to high pressures. Compressors are used to increase the pressure of hydrogen gas, making it suitable for storage and dispensing. During this process, impurities and particulates can be introduced, which could potentially damage the compressor or affect the quality of the hydrogen gas. High-pressure hydrogen filters are installed at both the front and rear ends of the compressor to remove these contaminants, ensuring that the hydrogen remains pure and safe for use. In the hydrogen dispenser interior, high-pressure hydrogen filters are crucial for ensuring the safe and efficient transfer of hydrogen gas from the storage tanks to the vehicle. The dispenser is the point at which hydrogen is delivered to the vehicle, and any impurities or particulates in the hydrogen gas could potentially damage the vehicle's fuel cell or other components. By filtering the hydrogen gas before it reaches the dispenser, these filters help to maintain the integrity and performance of the vehicle's fuel system. At the hydrogen storage tank outlet, high-pressure hydrogen filters are used to ensure that the hydrogen gas being dispensed is free from contaminants. Storage tanks are used to hold hydrogen gas at high pressures until it is needed for refueling. During storage, impurities can accumulate, which could affect the quality of the hydrogen gas. By installing filters at the tank outlet, these contaminants are removed before the hydrogen is dispensed, ensuring that the gas remains pure and safe for use. The use of high-pressure hydrogen filters in these critical areas of hydrogen refueling stations is essential for maintaining the safety, efficiency, and reliability of the refueling process. As the demand for hydrogen fuel cell vehicles continues to grow, the need for high-quality refueling infrastructure will become increasingly important. By ensuring the purity and quality of hydrogen gas, these filters play a vital role in supporting the widespread adoption of hydrogen as a clean and sustainable energy source.

Global High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market Outlook:

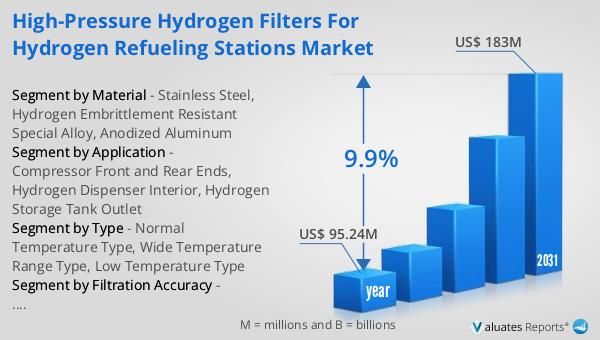

The global market for High-Pressure Hydrogen Filters for Hydrogen Refueling Stations was valued at approximately $95.24 million in 2024. It is anticipated to expand significantly, reaching an estimated value of $183 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 9.9% over the forecast period. This upward trend reflects the increasing demand for hydrogen as a clean energy source and the corresponding need for efficient and reliable refueling infrastructure. The market's expansion is driven by several factors, including advancements in hydrogen technology, supportive government policies, and the growing adoption of hydrogen fuel cell vehicles. As more countries and industries invest in hydrogen as a sustainable energy solution, the demand for high-pressure hydrogen filters is expected to rise. These filters are essential for ensuring the safety and efficiency of hydrogen refueling stations, making them a critical component in the transition to a hydrogen-based economy. The projected growth of this market highlights the importance of continued innovation and investment in hydrogen technology to support the global shift towards cleaner energy solutions.

| Report Metric | Details |

| Report Name | High-Pressure Hydrogen Filters for Hydrogen Refueling Stations Market |

| Accounted market size in year | US$ 95.24 million |

| Forecasted market size in 2031 | US$ 183 million |

| CAGR | 9.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Filtration Accuracy |

|

| Segment by Material |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, Hydac, Pall Corporation, Walker Filtration, Classic Filters, Norman Filters, Fujikin Incorporated, Donalson, WEH GmbH, Maximator GmbH, cmc Instruments GmbH, Chase Filters & Components, EV Hydrogen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |