What is Global Inclined Touch all-in-one Machine Market?

The Global Inclined Touch all-in-one Machine Market refers to the market for devices that integrate touch screen technology with various functionalities in a single unit, designed with an inclined or angled display. These machines are used in a variety of settings, including public spaces, retail environments, educational institutions, and industrial applications. The inclined design enhances user interaction by providing a more ergonomic and accessible interface, making it easier for users to engage with the content displayed. These machines often come equipped with advanced features such as multi-touch capabilities, high-resolution displays, and robust processing power, allowing them to handle complex tasks and provide a seamless user experience. The market for these devices is driven by the increasing demand for interactive and user-friendly interfaces in various sectors, as well as advancements in touch screen technology that have made these machines more affordable and versatile.

800mm, 1000mm, Others in the Global Inclined Touch all-in-one Machine Market:

In the Global Inclined Touch all-in-one Machine Market, devices are categorized based on their screen sizes, such as 800mm, 1000mm, and others. The 800mm category typically includes machines with screens around 31.5 inches, which are often used in environments where space is limited but a high level of interactivity is required. These machines are popular in retail settings for point-of-sale systems, information kiosks, and digital signage. The 1000mm category, which includes screens around 39.4 inches, is suited for applications that require a larger display area, such as educational institutions, conference rooms, and control centers. These machines provide a more immersive experience and can display more information simultaneously, making them ideal for collaborative work and presentations. The "Others" category encompasses machines with screen sizes that do not fall into the 800mm or 1000mm categories, offering a range of options to meet specific needs and preferences. These machines can be customized for specialized applications, such as industrial automation, healthcare, and gaming. The versatility of these devices, combined with their advanced touch screen technology, makes them suitable for a wide range of uses, from enhancing customer engagement in retail environments to improving operational efficiency in industrial settings. The market for these machines is expected to grow as more industries recognize the benefits of interactive and user-friendly interfaces, and as technology continues to evolve, offering even more capabilities and features.

Public Spaces, Machinery, Others in the Global Inclined Touch all-in-one Machine Market:

The usage of Global Inclined Touch all-in-one Machines in public spaces, machinery, and other areas highlights their versatility and adaptability. In public spaces, these machines are commonly used for information kiosks, wayfinding systems, and interactive displays. They provide an engaging and intuitive way for people to access information, navigate large areas, and interact with digital content. For example, in airports, shopping malls, and museums, inclined touch all-in-one machines help visitors find their way, learn about exhibits, and access services. In the machinery sector, these devices are used for human-machine interfaces (HMIs) in industrial automation, control systems, and monitoring applications. Their ergonomic design and advanced touch capabilities make them ideal for use in environments where operators need to interact with complex systems efficiently and accurately. These machines can display real-time data, control machinery, and provide alerts, enhancing productivity and safety. In other areas, such as healthcare, education, and entertainment, inclined touch all-in-one machines offer numerous benefits. In healthcare, they can be used for patient check-in systems, digital signage, and interactive patient education. In education, they enhance learning experiences by providing interactive whiteboards, digital textbooks, and collaborative tools. In entertainment, these machines are used for gaming, virtual reality experiences, and interactive exhibits. The adaptability of inclined touch all-in-one machines makes them valuable tools in a wide range of applications, improving user experiences and operational efficiency across various sectors.

Global Inclined Touch all-in-one Machine Market Outlook:

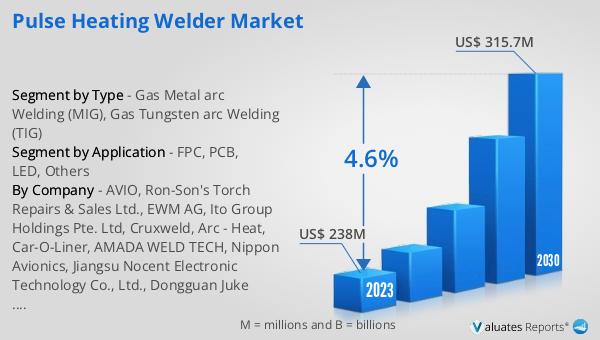

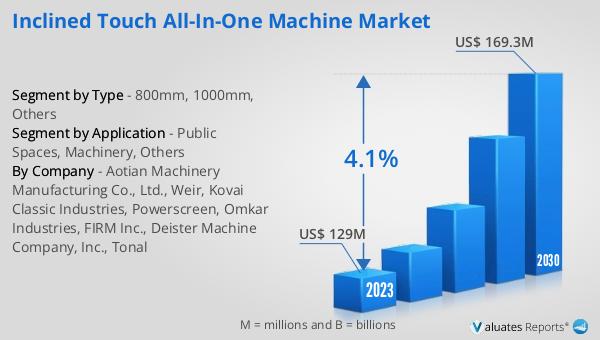

The global Inclined Touch all-in-one Machine market was valued at US$ 129 million in 2023 and is anticipated to reach US$ 169.3 million by 2030, witnessing a CAGR of 4.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing adoption of interactive touch screen technology across various industries. The demand for user-friendly and ergonomic interfaces is rising, as businesses and institutions seek to enhance customer engagement, improve operational efficiency, and provide better user experiences. The growth in this market is also supported by technological advancements that have made these machines more affordable and versatile, allowing for a wider range of applications. As more sectors recognize the benefits of inclined touch all-in-one machines, the market is expected to continue its upward trend, offering new opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Inclined Touch all-in-one Machine Market |

| Accounted market size in 2023 | US$ 129 million |

| Forecasted market size in 2030 | US$ 169.3 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aotian Machinery Manufacturing Co., Ltd., Weir, Kovai Classic Industries, Powerscreen, Omkar Industries, FIRM Inc., Deister Machine Company, Inc., Tonal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |