What is Global Kegel Exercise System Market?

The Global Kegel Exercise System Market refers to the worldwide industry focused on products and devices designed to help individuals perform Kegel exercises. Kegel exercises are pelvic floor exercises that strengthen the muscles of the pelvic floor, which support the bladder, uterus, and bowels. These exercises are beneficial for both men and women, helping to improve bladder control, enhance sexual health, and support overall pelvic health. The market includes a variety of products such as Kegel exercise balls, electronic Kegel exercisers, and biofeedback Kegel trainers. These products are used by individuals seeking to improve their pelvic floor strength, often recommended by healthcare professionals for conditions like urinary incontinence, pelvic organ prolapse, and postpartum recovery. The market is driven by increasing awareness of pelvic health, advancements in technology, and the growing prevalence of pelvic floor disorders.

Kegel Exercise Balls, Electronic Kegel Exercisers, Biofeedback Kegel Trainers in the Global Kegel Exercise System Market:

Kegel exercise balls, electronic Kegel exercisers, and biofeedback Kegel trainers are key components of the Global Kegel Exercise System Market. Kegel exercise balls, also known as Ben Wa balls or vaginal weights, are small, weighted devices that are inserted into the vagina to help women perform Kegel exercises. The weight of the balls encourages the pelvic floor muscles to contract, thereby strengthening them over time. These balls come in various sizes and weights, allowing users to gradually increase the difficulty of their exercises as their muscles become stronger. Electronic Kegel exercisers, on the other hand, are devices that use electrical stimulation to induce muscle contractions in the pelvic floor. These devices often come with various settings and programs that can be customized to the user's needs, making them suitable for individuals with different levels of pelvic floor strength. Biofeedback Kegel trainers are advanced devices that provide real-time feedback on the user's pelvic floor muscle activity. These trainers often come with sensors that detect muscle contractions and provide visual or auditory feedback, helping users to perform their exercises more effectively. Biofeedback trainers are particularly useful for individuals who have difficulty identifying their pelvic floor muscles or who need additional motivation to perform their exercises regularly. The Global Kegel Exercise System Market is characterized by a wide range of products that cater to different needs and preferences, making it accessible to a broad audience.

Female, Male in the Global Kegel Exercise System Market:

The usage of the Global Kegel Exercise System Market spans across both female and male demographics, addressing various health concerns and improving overall pelvic health. For females, Kegel exercises are particularly beneficial for strengthening the pelvic floor muscles, which can become weakened due to childbirth, aging, or other factors. Women often use Kegel exercise balls, electronic Kegel exercisers, and biofeedback Kegel trainers to improve bladder control, reduce the risk of pelvic organ prolapse, and enhance sexual health. These exercises are also recommended for postpartum recovery, helping new mothers regain pelvic floor strength and reduce the risk of urinary incontinence. For males, Kegel exercises are equally important, although they are less commonly discussed. Men can benefit from Kegel exercises to improve bladder control, particularly after prostate surgery, and to enhance sexual health by improving erectile function and preventing premature ejaculation. Electronic Kegel exercisers and biofeedback Kegel trainers are particularly useful for men, as they provide guidance and feedback on the effectiveness of their exercises. The Global Kegel Exercise System Market offers a variety of products that cater to the unique needs of both men and women, making it an essential component of overall health and wellness.

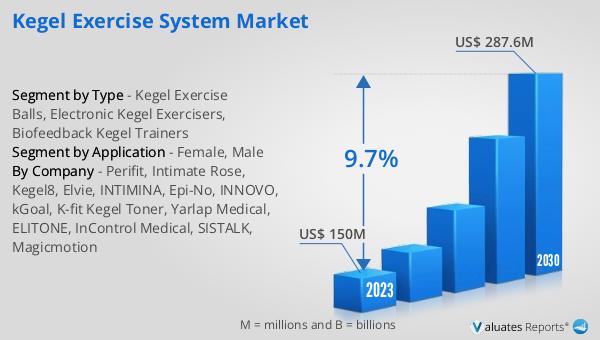

Global Kegel Exercise System Market Outlook:

The global Kegel Exercise System market was valued at US$ 150 million in 2023 and is anticipated to reach US$ 287.6 million by 2030, witnessing a compound annual growth rate (CAGR) of 9.7% during the forecast period from 2024 to 2030. This significant growth is driven by increasing awareness of pelvic health, advancements in technology, and the growing prevalence of pelvic floor disorders. The market includes a wide range of products such as Kegel exercise balls, electronic Kegel exercisers, and biofeedback Kegel trainers, which cater to the needs of both men and women. As more individuals become aware of the benefits of Kegel exercises for improving bladder control, enhancing sexual health, and supporting overall pelvic health, the demand for these products is expected to continue to rise. The market's growth is also supported by the increasing number of healthcare professionals recommending Kegel exercises for conditions like urinary incontinence, pelvic organ prolapse, and postpartum recovery. With a diverse range of products available, the Global Kegel Exercise System Market is well-positioned to meet the needs of a broad audience, driving its continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Kegel Exercise System Market |

| Accounted market size in 2023 | US$ 150 million |

| Forecasted market size in 2030 | US$ 287.6 million |

| CAGR | 9.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Perifit, Intimate Rose, Kegel8, Elvie, INTIMINA, Epi-No, INNOVO, kGoal, K-fit Kegel Toner, Yarlap Medical, ELITONE, InControl Medical, SISTALK, Magicmotion |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |