What is Global Particleboard Panels Market?

The Global Particleboard Panels Market refers to the worldwide industry involved in the production, distribution, and sale of particleboard panels. Particleboard is a type of engineered wood product made from wood chips, sawmill shavings, or even sawdust, which are bonded together with a synthetic resin or other suitable binder, and then pressed and extruded. These panels are widely used in various applications due to their cost-effectiveness, versatility, and ease of use. The market encompasses a range of products, including raw particleboard, fire-resistant particleboard, and moisture-resistant particleboard, each designed to meet specific needs and requirements. The demand for particleboard panels is driven by their extensive use in furniture manufacturing, interior decoration, construction, and other industries. The market is influenced by factors such as economic conditions, technological advancements, and environmental regulations. As the construction and furniture industries continue to grow, the global particleboard panels market is expected to expand, offering numerous opportunities for manufacturers, suppliers, and other stakeholders involved in this sector.

Raw Particleboard, Fire Resistant Particleboard, Moisture Resistant Particleboard in the Global Particleboard Panels Market:

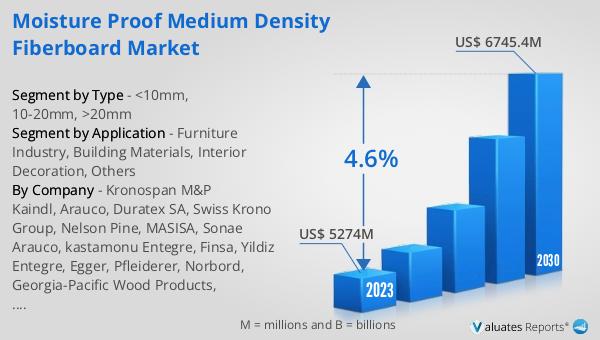

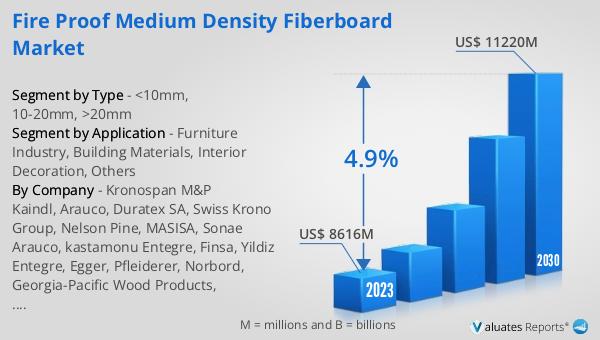

Raw particleboard, fire-resistant particleboard, and moisture-resistant particleboard are three key types of particleboard panels that cater to different needs within the global particleboard panels market. Raw particleboard is the most basic form of particleboard, made from wood particles bonded together with a resin. It is widely used in furniture manufacturing, cabinetry, and shelving due to its affordability and ease of machining. However, raw particleboard is susceptible to moisture and fire, which limits its use in certain applications. To address these limitations, fire-resistant particleboard has been developed. This type of particleboard is treated with fire-retardant chemicals that enhance its ability to withstand high temperatures and slow down the spread of flames. Fire-resistant particleboard is commonly used in construction projects where fire safety is a priority, such as in wall paneling, ceilings, and partition walls. On the other hand, moisture-resistant particleboard is designed to withstand exposure to humidity and moisture. It is treated with water-repellent chemicals that prevent swelling and warping, making it suitable for use in areas prone to dampness, such as kitchens, bathrooms, and flooring. The development of these specialized particleboard panels has expanded the range of applications for particleboard, making it a versatile and valuable material in various industries. Each type of particleboard offers unique benefits and is chosen based on the specific requirements of the project, ensuring that the final product meets the desired standards of performance and durability.

Furniture and Interior Decoration, Ceiling and Wall Paneling, Partition Walls, Doors, Flooring, Others in the Global Particleboard Panels Market:

The global particleboard panels market finds extensive usage in various areas, including furniture and interior decoration, ceiling and wall paneling, partition walls, doors, flooring, and other applications. In the realm of furniture and interior decoration, particleboard panels are a popular choice due to their cost-effectiveness and versatility. They are used to manufacture a wide range of furniture items, including cabinets, shelves, tables, and wardrobes. The smooth surface of particleboard allows for easy lamination and veneering, enabling manufacturers to create aesthetically pleasing and durable furniture pieces. In ceiling and wall paneling, particleboard panels provide an affordable and efficient solution for creating smooth and even surfaces. They are easy to install and can be painted or covered with decorative finishes to enhance the visual appeal of interiors. For partition walls, particleboard panels offer a lightweight and cost-effective alternative to traditional building materials. They are easy to cut and shape, allowing for quick and flexible installation in both residential and commercial spaces. When it comes to doors, particleboard panels are often used as core materials due to their stability and strength. They provide a solid foundation for door construction, ensuring durability and resistance to warping. In flooring applications, moisture-resistant particleboard panels are particularly valuable. They provide a stable and durable base for various types of flooring, including laminate, vinyl, and carpet. The moisture-resistant properties of these panels prevent swelling and warping, ensuring a long-lasting and reliable flooring solution. Additionally, particleboard panels are used in other applications such as packaging, exhibition stands, and DIY projects. Their versatility, affordability, and ease of use make them a preferred choice for a wide range of applications, driving the demand for particleboard panels in the global market.

Global Particleboard Panels Market Outlook:

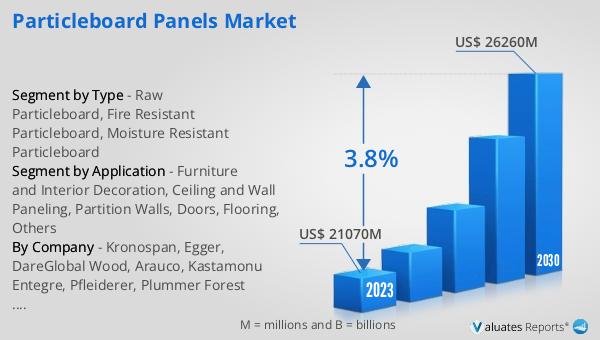

The global particleboard panels market was valued at approximately USD 21,070 million in 2023 and is projected to reach around USD 26,260 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for particleboard panels across various industries, driven by their cost-effectiveness, versatility, and wide range of applications. The market's expansion is supported by the continuous growth of the construction and furniture industries, which are major consumers of particleboard panels. As these industries evolve and innovate, the demand for specialized particleboard products, such as fire-resistant and moisture-resistant panels, is expected to rise. Additionally, advancements in manufacturing technologies and the development of eco-friendly and sustainable particleboard options are likely to contribute to the market's growth. The global particleboard panels market presents numerous opportunities for manufacturers, suppliers, and other stakeholders to capitalize on the increasing demand and expand their market presence.

| Report Metric | Details |

| Report Name | Particleboard Panels Market |

| Accounted market size in 2023 | US$ 21070 million |

| Forecasted market size in 2030 | US$ 26260 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Kronospan, Egger, DareGlobal Wood, Arauco, Kastamonu Entegre, Pfleiderer, Plummer Forest Products, Evergreen Group, Kopine, Efanor, Swiss Krono, Roseburg, Georgia-Pacific, Masisa, Treezo Group, Fenglin Group, Ningfeng Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |