What is Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market?

The Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market is a specialized segment within the broader thermal processing equipment industry. Rapid Thermal Annealing (RTA) is a process used to heat materials quickly to high temperatures and then cool them down rapidly. This technique is crucial in the semiconductor industry for activating dopants, repairing damage caused by ion implantation, and improving the electrical properties of materials. The vacuum furnace aspect ensures that the process occurs in a controlled environment, free from contaminants that could affect the quality of the materials being treated. The market for these furnaces is driven by the increasing demand for advanced semiconductor devices, which require precise and efficient thermal processing. Additionally, the growing adoption of RTA technology in other industries, such as photovoltaics and MEMS (Micro-Electro-Mechanical Systems), is contributing to market growth. The market is characterized by technological advancements, with manufacturers focusing on developing more efficient and reliable furnaces to meet the evolving needs of their customers.

Tabletop Annealing Furnace, Compact Annealing Furnace, Mini Annealing Furnace in the Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market:

Tabletop Annealing Furnace, Compact Annealing Furnace, and Mini Annealing Furnace are three types of equipment within the Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market, each designed to meet specific needs and applications. The Tabletop Annealing Furnace is a small, portable unit ideal for research and development laboratories, educational institutions, and small-scale production environments. It offers precise temperature control and uniform heating, making it suitable for experiments and small-batch processing. The Compact Annealing Furnace, on the other hand, is slightly larger and designed for medium-scale production. It combines the benefits of a small footprint with higher throughput capabilities, making it ideal for pilot production lines and specialized manufacturing processes. The Mini Annealing Furnace is the smallest of the three, designed for ultra-compact applications where space is at a premium. Despite its small size, it offers high performance and reliability, making it suitable for niche applications such as MEMS fabrication and small-scale semiconductor processing. Each of these furnaces is equipped with advanced features such as rapid heating and cooling cycles, precise temperature control, and a vacuum environment to ensure high-quality results. The choice between these furnaces depends on the specific requirements of the application, including the size of the materials being processed, the desired throughput, and the available space. Manufacturers in the RTA vacuum furnace market are continually innovating to improve the performance and efficiency of these furnaces, incorporating advanced materials and control systems to meet the evolving needs of their customers. The Tabletop Annealing Furnace, for example, may feature advanced software for precise temperature profiling and data logging, while the Compact Annealing Furnace might include enhanced insulation and cooling systems to improve energy efficiency. The Mini Annealing Furnace, despite its small size, may incorporate high-performance heating elements and advanced vacuum technology to ensure consistent and reliable results. Overall, these furnaces play a crucial role in various industries, enabling precise thermal processing of materials and contributing to the development of advanced technologies.

Semiconductor, Others in the Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market:

The usage of Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market in the semiconductor industry is extensive and critical. Semiconductors are the backbone of modern electronics, and their manufacturing requires precise and controlled thermal processes. RTA vacuum furnaces are used to activate dopants, which are impurities added to semiconductors to change their electrical properties. This process involves heating the semiconductor material to high temperatures in a vacuum environment to ensure that the dopants are evenly distributed and activated without introducing contaminants. Additionally, RTA is used to repair damage caused by ion implantation, a process where ions are embedded into the semiconductor material to alter its properties. The rapid heating and cooling cycles of RTA furnaces help to anneal the material, restoring its crystalline structure and improving its electrical characteristics. Beyond the semiconductor industry, RTA vacuum furnaces find applications in other areas such as photovoltaics, MEMS (Micro-Electro-Mechanical Systems), and advanced materials research. In the photovoltaic industry, RTA is used to improve the efficiency of solar cells by optimizing the electrical properties of the materials used. This involves precise thermal processing to enhance the performance and durability of the solar cells. In MEMS fabrication, RTA is used to anneal thin films and other materials, ensuring that they have the desired mechanical and electrical properties. This is crucial for the development of high-performance MEMS devices used in various applications, including sensors, actuators, and microelectronics. Advanced materials research also benefits from the use of RTA vacuum furnaces, as they enable scientists to study the effects of rapid thermal processing on different materials. This research can lead to the development of new materials with improved properties for various applications. Overall, the Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market plays a vital role in enabling the precise and controlled thermal processing required for the development and manufacturing of advanced technologies in various industries.

Global Rapid Thermal Annealing (RTA) Vacuum Furnace Market Outlook:

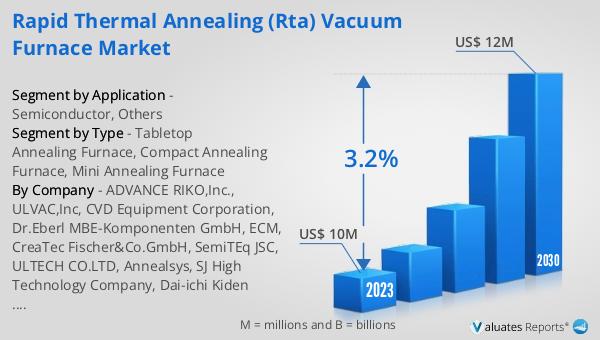

The global Rapid Thermal Annealing (RTA) Vacuum Furnace market was valued at US$ 10 million in 2023 and is anticipated to reach US$ 12 million by 2030, witnessing a CAGR of 3.2% during the forecast period from 2024 to 2030. This market growth is driven by the increasing demand for advanced semiconductor devices and the adoption of RTA technology in other industries such as photovoltaics and MEMS. The market is characterized by technological advancements, with manufacturers focusing on developing more efficient and reliable furnaces to meet the evolving needs of their customers. The growth in this market reflects the critical role that RTA vacuum furnaces play in enabling precise and controlled thermal processing required for the development and manufacturing of advanced technologies. As industries continue to innovate and develop new applications for RTA technology, the market is expected to see sustained growth in the coming years.

| Report Metric | Details |

| Report Name | Rapid Thermal Annealing (RTA) Vacuum Furnace Market |

| Accounted market size in 2023 | US$ 10 million |

| Forecasted market size in 2030 | US$ 12 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ADVANCE RIKO,Inc., ULVAC,Inc, CVD Equipment Corporation, Dr.Eberl MBE-Komponenten GmbH, ECM, CreaTec Fischer&Co.GmbH, SemiTEq JSC, ULTECH CO.LTD, Annealsys, SJ High Technology Company, Dai-ichi Kiden Co.,Ltd, Koyo Thermo Systems Co.,Ltd., Mattson Technology, Kokusai Electric, Centrotherm, Henan Chengyi Equipment Technology Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |