What is Global Zirconia Disc Market?

The Global Zirconia Disc Market refers to the worldwide industry focused on the production, distribution, and utilization of zirconia discs. Zirconia discs are primarily used in dental applications due to their exceptional strength, durability, and aesthetic qualities. These discs are made from zirconium dioxide, a ceramic material known for its high resistance to fracture and wear. The market encompasses various types of zirconia discs, including those with different levels of translucency and shades to match natural teeth. The demand for zirconia discs is driven by the growing adoption of digital dentistry, advancements in dental materials, and the increasing preference for metal-free restorations. Additionally, the market is influenced by factors such as the rising prevalence of dental disorders, the aging population, and the growing awareness of oral health. The global zirconia disc market is characterized by the presence of numerous manufacturers and suppliers, each offering a range of products to cater to the diverse needs of dental professionals and patients.

Standard Translucency (ST), High Translucency, Ultra High Translucency (UHT) in the Global Zirconia Disc Market:

In the Global Zirconia Disc Market, the translucency of zirconia discs is a critical factor that influences their application and performance. Standard Translucency (ST) zirconia discs are the most commonly used type, offering a balance between strength and aesthetics. These discs are suitable for a wide range of dental restorations, including crowns, bridges, and implant-supported restorations. They provide sufficient translucency to mimic the appearance of natural teeth while maintaining the necessary strength to withstand the forces of chewing and biting. High Translucency (HT) zirconia discs, on the other hand, offer enhanced aesthetic qualities due to their higher translucency. These discs are ideal for anterior restorations, where the appearance of the restoration is of utmost importance. HT zirconia discs allow for a more natural-looking result, closely resembling the translucency and color of natural teeth. Ultra High Translucency (UHT) zirconia discs represent the latest advancement in zirconia materials, offering the highest level of translucency available. These discs are designed for the most demanding aesthetic cases, providing an unparalleled level of natural appearance. UHT zirconia discs are often used in situations where the restoration is highly visible, such as in the front teeth. Despite their high translucency, UHT zirconia discs still maintain a significant level of strength, making them suitable for a variety of dental applications. The choice between ST, HT, and UHT zirconia discs depends on the specific needs of the patient and the clinical situation. Dental professionals must consider factors such as the location of the restoration, the patient's bite force, and the desired aesthetic outcome when selecting the appropriate type of zirconia disc. The availability of these different levels of translucency allows for a more personalized approach to dental restorations, ensuring that each patient receives the most suitable and effective treatment.

Anterior Crown, Posterior Crown, Others in the Global Zirconia Disc Market:

The Global Zirconia Disc Market finds extensive usage in various dental applications, including anterior crowns, posterior crowns, and other types of restorations. Anterior crowns are dental restorations used to replace or cover the front teeth, which are highly visible when a person smiles or talks. Zirconia discs are particularly well-suited for anterior crowns due to their excellent aesthetic properties. The high translucency of zirconia discs allows for a natural-looking restoration that closely matches the appearance of natural teeth. Additionally, zirconia's strength and durability ensure that the anterior crowns can withstand the daily wear and tear of biting and chewing. Posterior crowns, on the other hand, are used to restore the back teeth, which are subjected to higher biting forces. Zirconia discs are an ideal choice for posterior crowns due to their exceptional strength and resistance to fracture. The material's durability ensures that the restorations can endure the significant forces exerted during chewing, providing long-lasting and reliable results. Furthermore, zirconia's biocompatibility makes it a safe and suitable option for dental restorations, minimizing the risk of adverse reactions or complications. In addition to anterior and posterior crowns, zirconia discs are also used in other dental restorations, such as bridges, inlays, onlays, and implant-supported restorations. Bridges are used to replace one or more missing teeth by anchoring the restoration to the adjacent teeth. Zirconia discs provide the necessary strength and aesthetics for bridges, ensuring a seamless and natural-looking result. Inlays and onlays are used to restore damaged or decayed teeth, and zirconia discs offer a durable and aesthetically pleasing solution for these types of restorations. Implant-supported restorations involve the use of dental implants to replace missing teeth, and zirconia discs are often used to create the crowns or bridges that are attached to the implants. The versatility of zirconia discs makes them a valuable material in modern dentistry, providing a wide range of solutions for various dental needs.

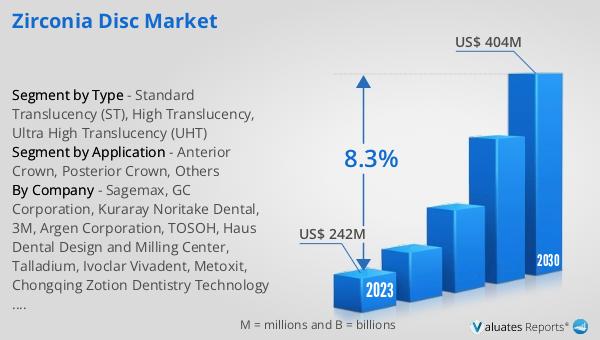

Global Zirconia Disc Market Outlook:

The global market for zirconia discs was valued at $242 million in 2023 and is projected to grow significantly, reaching $404 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.3% over the forecast period from 2024 to 2030. The increasing demand for zirconia discs can be attributed to several factors, including advancements in dental technology, the growing preference for metal-free restorations, and the rising awareness of oral health. As more dental professionals and patients recognize the benefits of zirconia discs, such as their strength, durability, and aesthetic qualities, the market is expected to continue its upward trajectory. The expanding aging population and the increasing prevalence of dental disorders also contribute to the growing demand for zirconia discs. Additionally, the market is characterized by the presence of numerous manufacturers and suppliers, each offering a range of products to cater to the diverse needs of dental professionals and patients. The competitive landscape of the market drives innovation and the development of new and improved zirconia disc products, further fueling market growth. Overall, the global zirconia disc market is poised for significant expansion in the coming years, driven by the increasing adoption of digital dentistry and the growing demand for high-quality dental restorations.

| Report Metric | Details |

| Report Name | Zirconia Disc Market |

| Accounted market size in 2023 | US$ 242 million |

| Forecasted market size in 2030 | US$ 404 million |

| CAGR | 8.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Sagemax, GC Corporation, Kuraray Noritake Dental, 3M, Argen Corporation, TOSOH, Haus Dental Design and Milling Center, Talladium, Ivoclar Vivadent, Metoxit, Chongqing Zotion Dentistry Technology Co.Ltd, Ceradirect, Dentsply Sirona, Dental Direkt, Zirkonzahn, DMAX, Doceram, Pritidenta, Besmile Biotechnology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |