What is Global Volumetric Doser Market?

The Global Volumetric Doser Market is a specialized segment within the broader industrial equipment market, focusing on devices that precisely measure and dispense materials by volume. These dosers are essential in various industries, including pharmaceuticals, chemicals, plastics, and food processing, where accurate dosing of liquids, powders, or granules is critical for maintaining product quality and consistency. The market encompasses a range of products, from simple manual dosers to sophisticated automated systems that integrate with production lines. The demand for volumetric dosers is driven by the need for precision, efficiency, and automation in manufacturing processes. As industries continue to evolve and adopt more advanced technologies, the Global Volumetric Doser Market is expected to grow, offering innovative solutions to meet the increasing demands for accuracy and productivity.

Volumetric Doser, Micro Volumetric Doser in the Global Volumetric Doser Market:

Volumetric dosers are devices designed to dispense precise volumes of materials, ensuring consistent and accurate dosing in various industrial applications. These devices are crucial in maintaining product quality and reducing waste. A micro volumetric doser, on the other hand, is a more specialized version designed for applications requiring extremely small and precise doses, often in the range of microliters or even nanoliters. In the context of the Global Volumetric Doser Market, these devices are used across a wide range of industries. For instance, in the pharmaceutical industry, volumetric dosers are used to dispense active ingredients and excipients accurately, ensuring the correct dosage in each tablet or capsule. In the chemical industry, they are used to mix and dispense chemicals with high precision, which is essential for maintaining the integrity of chemical reactions and processes. The food processing industry also relies on volumetric dosers to ensure consistent flavoring, coloring, and ingredient mixing, which is crucial for product quality and consumer satisfaction. The micro volumetric doser is particularly important in applications where even the slightest deviation in dosage can have significant consequences. For example, in the pharmaceutical industry, micro dosers are used in the production of highly potent drugs, where precise dosing is critical for patient safety and efficacy. In the electronics industry, micro dosers are used to apply tiny amounts of adhesives or coatings to delicate components, ensuring precision and reliability in the final product. The Global Volumetric Doser Market is characterized by continuous innovation, with manufacturers developing new technologies to improve accuracy, efficiency, and ease of use. This includes advancements in automation, integration with digital control systems, and the use of advanced materials to enhance durability and performance. As industries continue to demand higher levels of precision and efficiency, the market for volumetric dosers, including micro volumetric dosers, is expected to grow, driven by the need for reliable and accurate dosing solutions.

Injection Molding, Blow Molding in the Global Volumetric Doser Market:

The Global Volumetric Doser Market plays a crucial role in the injection molding and blow molding industries, where precise dosing of materials is essential for producing high-quality products. In injection molding, volumetric dosers are used to accurately measure and dispense plastic resins into the mold. This ensures that each part produced has the correct amount of material, leading to consistent quality and reducing waste. The use of volumetric dosers in injection molding also helps in maintaining the correct ratio of additives, such as colorants or stabilizers, which are critical for achieving the desired properties in the final product. By ensuring precise dosing, manufacturers can produce parts with consistent color, strength, and other characteristics, which is essential for meeting customer specifications and regulatory requirements. In blow molding, volumetric dosers are used to dispense the correct amount of plastic material into the mold, ensuring that the final product has the desired thickness and strength. This is particularly important in the production of bottles and containers, where uniform wall thickness is crucial for maintaining product integrity and preventing leaks. Volumetric dosers also help in reducing material waste, as they ensure that only the necessary amount of material is used in each cycle. This not only reduces production costs but also minimizes the environmental impact of the manufacturing process. The integration of volumetric dosers with automated control systems further enhances their efficiency and accuracy. By using advanced sensors and feedback mechanisms, these systems can continuously monitor and adjust the dosing process, ensuring optimal performance and reducing the risk of errors. This is particularly important in high-volume production environments, where even small deviations in dosing can lead to significant quality issues and production delays. The Global Volumetric Doser Market is expected to continue growing as manufacturers seek to improve their production processes and meet the increasing demand for high-quality products. With advancements in technology and the ongoing trend towards automation, volumetric dosers will play an increasingly important role in the injection molding and blow molding industries, helping manufacturers achieve greater precision, efficiency, and sustainability in their operations.

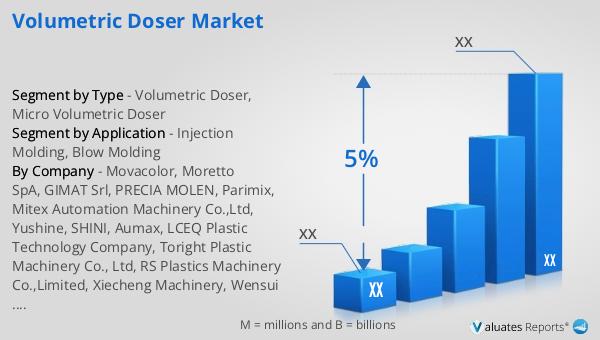

Global Volumetric Doser Market Outlook:

The global pharmaceutical market was valued at 1,475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown a steady increase, rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth highlights the expanding demand for pharmaceutical products and the critical role of chemical drugs within the industry. The increasing prevalence of chronic diseases, advancements in drug development, and the growing aging population are some of the key factors driving this growth. As the pharmaceutical market continues to expand, the need for precise and efficient dosing solutions, such as volumetric dosers, becomes increasingly important. These devices ensure accurate dispensing of active ingredients and excipients, which is essential for maintaining product quality and efficacy. The Global Volumetric Doser Market is poised to benefit from this growth, as manufacturers seek to improve their production processes and meet the rising demand for high-quality pharmaceutical products.

| Report Metric | Details |

| Report Name | Volumetric Doser Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Movacolor, Moretto SpA, GIMAT Srl, PRECIA MOLEN, Parimix, Mitex Automation Machinery Co.,Ltd, Yushine, SHINI, Aumax, LCEQ Plastic Technology Company, Toright Plastic Machinery Co., Ltd, RS Plastics Machinery Co.,Limited, Xiecheng Machinery, Wensui Plastics Machinery Group, RHONG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |