What is SMT AXI Inspection Equipment - Global Market?

SMT AXI Inspection Equipment, or Surface Mount Technology Automated X-ray Inspection Equipment, is a specialized tool used in the electronics manufacturing industry to ensure the quality and reliability of printed circuit boards (PCBs). These machines utilize X-ray technology to inspect the internal structures of PCBs, allowing manufacturers to detect defects such as solder joint issues, component misalignments, and other hidden anomalies that are not visible to the naked eye. The global market for SMT AXI Inspection Equipment is driven by the increasing demand for high-quality electronic devices, which necessitates stringent quality control measures. As electronics become more complex and miniaturized, the need for precise inspection tools like SMT AXI equipment becomes critical. This market is characterized by continuous technological advancements, with manufacturers striving to improve the accuracy, speed, and user-friendliness of their inspection systems. The equipment is widely used across various industries, including consumer electronics, telecommunications, and automotive, reflecting its versatility and importance in maintaining product quality and reliability.

Inline, Offline in the SMT AXI Inspection Equipment - Global Market:

Inline and offline SMT AXI Inspection Equipment are two primary configurations used in the electronics manufacturing process, each serving distinct roles based on production needs and operational setups. Inline SMT AXI systems are integrated directly into the production line, allowing for real-time inspection of PCBs as they move through the manufacturing process. This setup is particularly beneficial for high-volume production environments where speed and efficiency are paramount. Inline systems provide immediate feedback, enabling manufacturers to quickly identify and rectify defects, thus minimizing downtime and reducing the risk of defective products reaching the market. These systems are designed to handle large volumes of PCBs with minimal human intervention, making them ideal for large-scale operations. On the other hand, offline SMT AXI systems are standalone units that are not directly connected to the production line. They are typically used for batch processing or in environments where production volumes are lower, and the need for immediate inspection is not as critical. Offline systems offer greater flexibility, as they can be used to inspect a wide variety of PCB types and sizes without disrupting the main production line. This makes them suitable for smaller manufacturers or those producing specialized or custom electronics. Both inline and offline systems have their advantages and are chosen based on specific production requirements, cost considerations, and the level of inspection detail needed. Inline systems are generally more expensive due to their integration capabilities and higher throughput, while offline systems offer a more cost-effective solution for smaller operations. The choice between inline and offline SMT AXI Inspection Equipment ultimately depends on the manufacturer's production strategy, the complexity of the products being manufactured, and the desired balance between speed, accuracy, and cost. As the global market for SMT AXI Inspection Equipment continues to grow, manufacturers are increasingly looking for systems that offer a combination of high performance, reliability, and ease of use, regardless of whether they are inline or offline.

Consumer Electronics, Telecommunications Equipment, Automotive, Others in the SMT AXI Inspection Equipment - Global Market:

The usage of SMT AXI Inspection Equipment spans several key industries, each benefiting from the technology's ability to enhance product quality and reliability. In the consumer electronics sector, SMT AXI equipment is crucial for ensuring the performance and longevity of devices such as smartphones, tablets, and laptops. These products require highly reliable PCBs, as any defects can lead to malfunctions or reduced lifespan. By using SMT AXI systems, manufacturers can detect and address issues early in the production process, ensuring that only high-quality products reach consumers. In the telecommunications equipment industry, the demand for reliable and high-performance devices is equally critical. SMT AXI Inspection Equipment helps manufacturers maintain the integrity of complex PCBs used in networking equipment, routers, and communication devices. The ability to inspect solder joints and component placements with precision ensures that these devices can handle the demands of modern communication networks. The automotive industry also relies heavily on SMT AXI Inspection Equipment, as vehicles increasingly incorporate advanced electronic systems for safety, navigation, and entertainment. The reliability of these systems is paramount, as any failure can have serious consequences. SMT AXI systems provide the necessary inspection capabilities to ensure that automotive electronics meet stringent quality standards. Beyond these industries, SMT AXI Inspection Equipment is used in various other sectors, including aerospace, medical devices, and industrial electronics. In each case, the equipment plays a vital role in maintaining the quality and reliability of electronic components, which are essential for the safe and efficient operation of a wide range of products. As technology continues to advance and the demand for high-quality electronics grows, the importance of SMT AXI Inspection Equipment in these industries is expected to increase, driving further innovation and adoption.

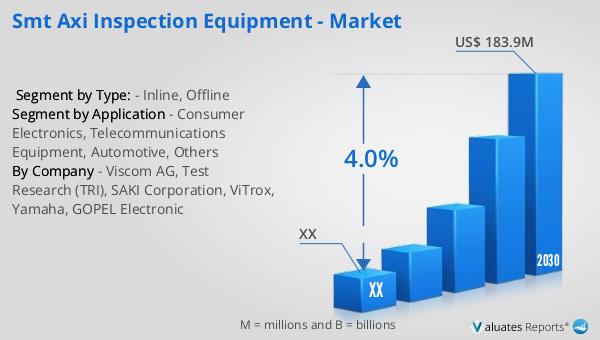

SMT AXI Inspection Equipment - Global Market Outlook:

The global market for SMT AXI Inspection Equipment was valued at approximately $140.3 million in 2023. It is projected to expand to a revised size of $183.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period from 2024 to 2030. This growth indicates a steady increase in demand for advanced inspection technologies as manufacturers strive to enhance the quality and reliability of electronic products. In North America, the market for SMT AXI Inspection Equipment was valued at a certain amount in 2023, with expectations to reach a specific value by 2030, maintaining a consistent CAGR throughout the forecast period. This regional growth underscores the importance of SMT AXI systems in supporting the robust electronics manufacturing sector in North America, where quality assurance and innovation are key competitive factors. The increasing complexity of electronic devices and the need for precise inspection solutions are driving the adoption of SMT AXI Inspection Equipment across various industries. As manufacturers continue to prioritize quality control and efficiency, the market for these advanced inspection systems is poised for sustained growth, reflecting their critical role in modern electronics production.

| Report Metric | Details |

| Report Name | SMT AXI Inspection Equipment - Market |

| Forecasted market size in 2030 | US$ 183.9 million |

| CAGR | 4.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Viscom AG, Test Research (TRI), SAKI Corporation, ViTrox, Yamaha, GOPEL Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |