What is High Pressure Waterjet Cutting Machine - Global Market?

High Pressure Waterjet Cutting Machines are advanced tools used in various industries to cut materials with precision using a high-pressure stream of water mixed with abrasive particles. This technology is highly valued for its ability to cut a wide range of materials, including metals, stone, glass, and composites, without generating heat, which can alter the material properties. The global market for these machines is expanding due to their versatility and efficiency. They are particularly popular in industries that require precise cutting without thermal distortion, such as aerospace, automotive, and manufacturing. The machines are also environmentally friendly, as they do not produce hazardous waste or fumes. The market is driven by technological advancements that enhance cutting speed and precision, as well as the growing demand for high-quality, intricate designs in various sectors. As industries continue to seek efficient and sustainable manufacturing solutions, the demand for high-pressure waterjet cutting machines is expected to grow, making them a crucial component in modern manufacturing processes.

Cantilever, Gantry in the High Pressure Waterjet Cutting Machine - Global Market:

Cantilever and gantry systems are two prevalent configurations in high-pressure waterjet cutting machines, each offering distinct advantages tailored to specific industrial needs. Cantilever waterjet cutting machines are characterized by their single-arm design, which provides easy access to the cutting table from three sides. This design is particularly advantageous for cutting large sheets of material, as it allows for easy loading and unloading. The cantilever system is often favored in applications where space is limited, as it requires less floor space compared to gantry systems. Additionally, the open design of cantilever machines facilitates maintenance and adjustments, making them user-friendly and efficient for operations that require frequent changes in setup or material type. On the other hand, gantry waterjet cutting machines are designed with a bridge-like structure that spans the cutting table, supported by two or more legs. This configuration provides superior stability and precision, making it ideal for heavy-duty cutting tasks and large-scale industrial applications. Gantry systems are capable of handling larger and thicker materials with ease, thanks to their robust construction and ability to support multiple cutting heads. This makes them a preferred choice in industries such as aerospace and automotive, where precision and reliability are paramount. The gantry design also allows for the integration of advanced features such as automated material handling and multi-axis cutting capabilities, further enhancing their versatility and efficiency. Both cantilever and gantry systems are integral to the global market for high-pressure waterjet cutting machines, catering to a diverse range of industrial applications. The choice between the two often depends on the specific requirements of the task at hand, including the size and type of material to be cut, the desired level of precision, and the available workspace. As the demand for high-quality, precise cutting solutions continues to grow across various industries, both cantilever and gantry waterjet cutting machines are expected to play a significant role in meeting these needs. Their ability to deliver clean, precise cuts without thermal distortion makes them indispensable tools in modern manufacturing, contributing to the ongoing evolution of industrial processes worldwide.

Metal Fabrication, Automotive, Industrial, Food Processing, Others in the High Pressure Waterjet Cutting Machine - Global Market:

High-pressure waterjet cutting machines are utilized across various industries due to their precision and versatility. In metal fabrication, these machines are indispensable for cutting intricate shapes and designs from metal sheets without causing thermal distortion. This capability is crucial for producing high-quality components that meet stringent industry standards. The automotive industry also benefits significantly from waterjet cutting technology, as it allows for the precise cutting of metal and composite materials used in vehicle manufacturing. This precision ensures that parts fit together seamlessly, enhancing the overall performance and safety of vehicles. In the industrial sector, waterjet cutting machines are used for a wide range of applications, from cutting machine parts to creating custom components for specialized equipment. Their ability to cut through thick and hard materials with ease makes them a valuable asset in heavy-duty industrial operations. The food processing industry also utilizes waterjet cutting machines, particularly for cutting frozen foods and other delicate products. The cold cutting process ensures that the food's texture and quality are preserved, making it an ideal solution for maintaining product integrity. Additionally, waterjet cutting machines are used in various other industries, including aerospace, electronics, and construction, where precision and efficiency are paramount. Their ability to cut a wide range of materials without generating heat or hazardous waste makes them an environmentally friendly and cost-effective solution for modern manufacturing challenges. As industries continue to evolve and demand more efficient and sustainable production methods, the use of high-pressure waterjet cutting machines is expected to increase, solidifying their role as a key technology in the global market.

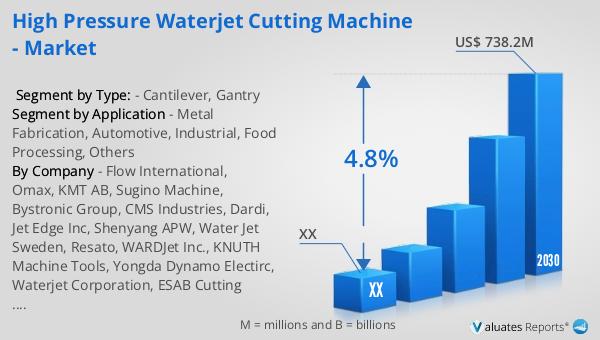

High Pressure Waterjet Cutting Machine - Global Market Outlook:

The global market for high-pressure waterjet cutting machines was valued at approximately $534.2 million in 2023. This market is projected to grow to a size of $738.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for precise and efficient cutting solutions across various industries. In North America, the market for high-pressure waterjet cutting machines was valued at a significant amount in 2023, with expectations of continued growth through 2030. The CAGR for this region during the forecast period is anticipated to be robust, driven by technological advancements and the growing adoption of waterjet cutting technology in manufacturing and industrial applications. The expansion of the market is also supported by the increasing need for environmentally friendly and sustainable manufacturing processes, which high-pressure waterjet cutting machines provide. As industries continue to prioritize efficiency and precision in their operations, the demand for these machines is expected to rise, contributing to the overall growth of the global market. The versatility and effectiveness of high-pressure waterjet cutting machines make them an essential tool in modern manufacturing, and their market outlook remains positive as industries seek innovative solutions to meet evolving production demands.

| Report Metric | Details |

| Report Name | High Pressure Waterjet Cutting Machine - Market |

| Forecasted market size in 2030 | US$ 738.2 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flow International, Omax, KMT AB, Sugino Machine, Bystronic Group, CMS Industries, Dardi, Jet Edge Inc, Shenyang APW, Water Jet Sweden, Resato, WARDJet Inc., KNUTH Machine Tools, Yongda Dynamo Electirc, Waterjet Corporation, ESAB Cutting Systems, H.G. Ridder, MicroStep, Perndorfer Maschinenbau KG, KIMLA, Eckert, TECHNI Waterjet |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |