What is Global Screw Doser Market?

The Global Screw Doser Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to precisely measure and dispense granular and powdered materials. These screw dosers are essential in various industries, including pharmaceuticals, chemicals, food processing, and plastics, where accurate dosing is critical for product quality and consistency. The market encompasses a range of products, from simple manual dosers to sophisticated automated systems that integrate with larger production lines. The demand for screw dosers is driven by the need for efficiency, precision, and automation in manufacturing processes. As industries continue to evolve and adopt more advanced technologies, the Global Screw Doser Market is expected to grow, offering innovative solutions to meet the increasing demands for accuracy and productivity in material handling and dosing applications.

Volumetric Screw Doser, Gravimetric Screw Doser in the Global Screw Doser Market:

Volumetric screw dosers and gravimetric screw dosers are two primary types of dosing systems used in the Global Screw Doser Market. Volumetric screw dosers operate by dispensing a set volume of material per unit of time, making them suitable for applications where the bulk density of the material is consistent. These dosers are often used in industries where the primary concern is the volume of material being dispensed rather than its weight. They are relatively simple to operate and maintain, making them a cost-effective solution for many applications. On the other hand, gravimetric screw dosers measure the weight of the material being dispensed, providing a higher level of accuracy and consistency. These systems are equipped with load cells that continuously monitor the weight of the material, adjusting the feed rate to ensure precise dosing. Gravimetric dosers are ideal for applications where the bulk density of the material can vary, such as in the pharmaceutical and chemical industries, where precise dosing is critical for product quality and regulatory compliance. Both types of dosers have their advantages and are chosen based on the specific needs of the application. Volumetric dosers are typically used in applications where speed and simplicity are paramount, while gravimetric dosers are preferred in scenarios where accuracy and consistency are crucial. The choice between volumetric and gravimetric dosing systems depends on various factors, including the nature of the material being dosed, the required level of accuracy, and the specific requirements of the production process. As the Global Screw Doser Market continues to evolve, manufacturers are developing more advanced and versatile dosing systems to meet the diverse needs of different industries. These innovations include hybrid systems that combine the benefits of both volumetric and gravimetric dosing, offering greater flexibility and precision. Additionally, advancements in automation and control technologies are enabling more sophisticated dosing solutions, allowing for seamless integration with other production equipment and systems. This integration enhances overall efficiency and productivity, further driving the demand for advanced screw dosing systems in the global market.

Fine Granular Products, Low Density Powders in the Global Screw Doser Market:

The Global Screw Doser Market finds extensive usage in handling fine granular products and low-density powders, which are common in various industrial applications. Fine granular products, such as sugar, salt, and certain chemicals, require precise dosing to ensure consistent product quality and prevent wastage. Screw dosers are particularly effective in handling these materials due to their ability to provide accurate and controlled dispensing. In the food processing industry, for example, screw dosers are used to measure and dispense ingredients like spices, flavorings, and additives, ensuring that each batch of product meets the required specifications. Similarly, in the chemical industry, screw dosers are used to handle fine granular chemicals, ensuring precise dosing for various formulations and processes. Low-density powders, such as flour, talc, and certain pharmaceutical ingredients, also benefit from the use of screw dosers. These materials can be challenging to handle due to their tendency to become airborne and their variable bulk density. Screw dosers equipped with advanced control systems can accurately measure and dispense low-density powders, minimizing dust generation and ensuring consistent dosing. In the pharmaceutical industry, for instance, screw dosers are used to handle active pharmaceutical ingredients (APIs) and excipients, ensuring precise dosing for tablet and capsule production. The ability to accurately dose low-density powders is critical for maintaining product quality and meeting regulatory requirements. The versatility of screw dosers in handling both fine granular products and low-density powders makes them indispensable in various industries. Manufacturers are continually developing new technologies and features to enhance the performance and reliability of screw dosers, addressing the specific challenges associated with different materials. These advancements include improved screw designs, enhanced control systems, and integration with other production equipment. As industries continue to demand higher levels of precision and efficiency, the Global Screw Doser Market is expected to grow, offering innovative solutions to meet the evolving needs of different applications.

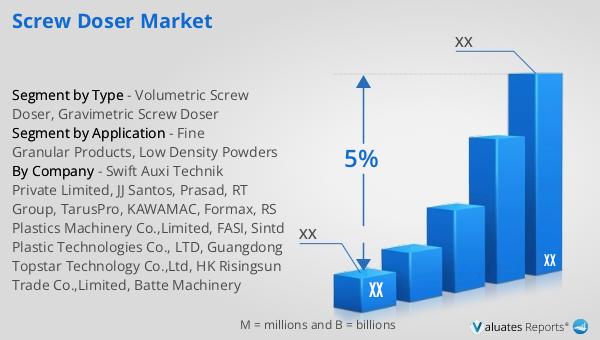

Global Screw Doser Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown significant growth, increasing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth reflects the rising demand for pharmaceutical products and the continuous advancements in drug development and manufacturing technologies. The increasing prevalence of chronic diseases, an aging population, and the ongoing need for innovative treatments are driving the expansion of the pharmaceutical market. Additionally, the chemical drug market's growth highlights the importance of traditional pharmaceuticals in addressing various health conditions. As the pharmaceutical and chemical drug markets continue to evolve, the demand for precise and efficient dosing systems, such as screw dosers, is expected to rise, supporting the production of high-quality pharmaceutical products.

| Report Metric | Details |

| Report Name | Screw Doser Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Swift Auxi Technik Private Limited, JJ Santos, Prasad, RT Group, TarusPro, KAWAMAC, Formax, RS Plastics Machinery Co.,Limited, FASI, Sintd Plastic Technologies Co., LTD, Guangdong Topstar Technology Co.,Ltd, HK Risingsun Trade Co.,Limited, Batte Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |