What is Global Electric Vehicle Seat Motor Market?

The Global Electric Vehicle Seat Motor Market refers to the industry focused on the production and distribution of motors specifically designed for the seats of electric vehicles (EVs). These motors are crucial components that enable various seat adjustments, such as reclining, height adjustment, and lumbar support, enhancing the comfort and ergonomics for the driver and passengers. As the demand for electric vehicles continues to rise due to environmental concerns and advancements in technology, the need for efficient and reliable seat motors also grows. These motors are typically small, powerful, and energy-efficient, designed to operate quietly and smoothly. The market encompasses a wide range of products from different manufacturers, each offering unique features and specifications to meet the diverse needs of EV manufacturers and consumers. The growth of this market is driven by the increasing adoption of electric vehicles globally, advancements in motor technology, and the rising consumer demand for enhanced comfort and customization in vehicle interiors.

Four Pole Motor, Two Pole Motor in the Global Electric Vehicle Seat Motor Market:

In the context of the Global Electric Vehicle Seat Motor Market, Four Pole Motors and Two Pole Motors are two primary types of motors used for seat adjustments. Four Pole Motors are characterized by having four magnetic poles, which means they complete one electrical cycle in two mechanical revolutions. This design allows for smoother and more precise control of the seat movements, making them ideal for applications requiring high torque and low speed. These motors are often used in premium electric vehicles where comfort and precision are paramount. On the other hand, Two Pole Motors have two magnetic poles and complete one electrical cycle in one mechanical revolution. They are generally faster and more efficient in terms of energy consumption, making them suitable for applications where speed is more critical than torque. These motors are commonly found in more economical electric vehicles where cost and efficiency are prioritized. Both types of motors have their unique advantages and are chosen based on the specific requirements of the vehicle and the preferences of the manufacturer. The choice between Four Pole and Two Pole Motors can significantly impact the overall performance, efficiency, and user experience of the electric vehicle seats.

BEV, PHEV in the Global Electric Vehicle Seat Motor Market:

The usage of Global Electric Vehicle Seat Motor Market in Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) is essential for enhancing the overall driving experience. In BEVs, which rely entirely on electric power, seat motors play a crucial role in providing comfort and convenience without compromising the vehicle's energy efficiency. These motors are designed to operate with minimal power consumption, ensuring that the vehicle's battery life is not significantly affected. The ability to adjust seats easily and precisely is particularly important in BEVs, where maximizing the driving range is a key concern. In PHEVs, which combine an internal combustion engine with an electric motor, seat motors also contribute to the overall comfort and functionality of the vehicle. Since PHEVs can switch between electric and gasoline power, the seat motors must be versatile and efficient to operate seamlessly in both modes. The integration of advanced seat motors in PHEVs helps in optimizing the use of electric power, thereby enhancing the vehicle's fuel efficiency and reducing emissions. Both BEVs and PHEVs benefit from the advancements in seat motor technology, which offer improved performance, durability, and user satisfaction.

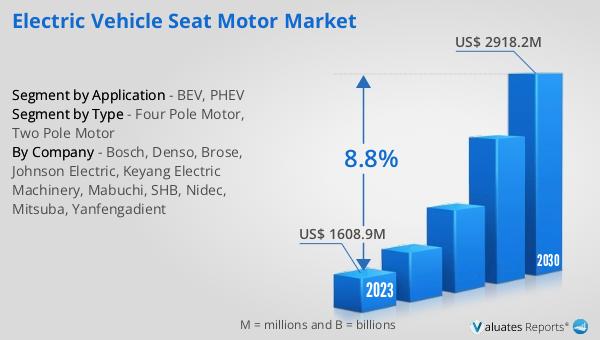

Global Electric Vehicle Seat Motor Market Outlook:

The global Electric Vehicle Seat Motor market was valued at US$ 1608.9 million in 2023 and is anticipated to reach US$ 2918.2 million by 2030, witnessing a CAGR of 8.8% during the forecast period 2024-2030. This significant growth reflects the increasing demand for electric vehicles and the corresponding need for advanced seat motors that enhance comfort and functionality. As more consumers and manufacturers prioritize sustainability and energy efficiency, the market for electric vehicle seat motors is expected to expand rapidly. The projected growth rate underscores the importance of continuous innovation and development in motor technology to meet the evolving needs of the electric vehicle industry.

| Report Metric | Details |

| Report Name | Electric Vehicle Seat Motor Market |

| Accounted market size in 2023 | US$ 1608.9 million |

| Forecasted market size in 2030 | US$ 2918.2 million |

| CAGR | 8.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bosch, Denso, Brose, Johnson Electric, Keyang Electric Machinery, Mabuchi, SHB, Nidec, Mitsuba, Yanfengadient |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |