What is Global Adhesive Delivery Systems Market?

The Global Adhesive Delivery Systems Market refers to the worldwide industry focused on the production, distribution, and application of systems designed to deliver adhesives efficiently and effectively. These systems are crucial in various industries, including automotive, electronics, construction, and packaging, where precise and reliable adhesive application is essential. Adhesive delivery systems encompass a range of technologies, from simple manual applicators to sophisticated automated systems that ensure consistent and accurate adhesive placement. The market is driven by the increasing demand for advanced adhesive solutions that enhance product performance, reduce waste, and improve manufacturing efficiency. Innovations in adhesive formulations and delivery technologies are continually evolving to meet the specific needs of different applications, making this market a dynamic and integral part of modern manufacturing processes. The growth of this market is also influenced by the rising trend towards automation and the need for environmentally friendly adhesive solutions. As industries continue to seek ways to improve productivity and sustainability, the Global Adhesive Delivery Systems Market is expected to expand, offering new opportunities for innovation and development.

Alloy Materials, Composite Material, Others in the Global Adhesive Delivery Systems Market:

Alloy materials, composite materials, and other materials play a significant role in the Global Adhesive Delivery Systems Market, each offering unique properties and benefits that cater to specific industrial needs. Alloy materials, which are combinations of metals, are widely used in adhesive delivery systems due to their strength, durability, and resistance to corrosion. These materials are particularly valuable in applications where the adhesive delivery system must withstand harsh environmental conditions or high mechanical stress. For example, in the automotive industry, alloy materials are used in adhesive applicators to ensure long-lasting performance and reliability. Composite materials, on the other hand, are engineered from two or more constituent materials with different physical or chemical properties. These materials are designed to achieve superior performance characteristics that are not possible with individual components alone. In the context of adhesive delivery systems, composite materials offer advantages such as lightweight, high strength, and resistance to wear and tear. This makes them ideal for use in industries like aerospace and electronics, where precision and durability are paramount. Other materials, including plastics and ceramics, also play a crucial role in the market. Plastics are often used in adhesive delivery systems for their versatility, ease of manufacturing, and cost-effectiveness. They can be molded into complex shapes and are suitable for a wide range of applications, from packaging to consumer electronics. Ceramics, known for their high-temperature resistance and electrical insulation properties, are used in specialized adhesive delivery systems where these characteristics are essential. The choice of material in adhesive delivery systems is influenced by factors such as the type of adhesive being used, the application environment, and the specific requirements of the end-use industry. As technology advances, new materials and material combinations are being developed to enhance the performance and efficiency of adhesive delivery systems. This ongoing innovation is driving the growth of the Global Adhesive Delivery Systems Market, as manufacturers seek to meet the evolving demands of various industries.

Photovoltaic, Power Battery, Automotive Electronics, Others in the Global Adhesive Delivery Systems Market:

The usage of Global Adhesive Delivery Systems Market spans across several critical areas, including photovoltaic, power battery, automotive electronics, and others, each with its unique requirements and challenges. In the photovoltaic industry, adhesive delivery systems are essential for the assembly and installation of solar panels. These systems ensure precise application of adhesives that bond solar cells to substrates, seal modules, and provide structural support. The reliability and efficiency of adhesive delivery systems directly impact the performance and longevity of solar panels, making them a vital component in the renewable energy sector. In the power battery industry, adhesive delivery systems are used in the manufacturing of batteries for electric vehicles and energy storage systems. These systems facilitate the accurate placement of adhesives that bond battery components, enhance thermal management, and improve overall battery performance. The demand for high-performance batteries is driving the need for advanced adhesive delivery systems that can meet stringent quality and safety standards. Automotive electronics is another area where adhesive delivery systems play a crucial role. Modern vehicles are equipped with numerous electronic components, such as sensors, control units, and infotainment systems, which require reliable adhesive solutions for assembly and protection. Adhesive delivery systems ensure that these components are securely bonded and protected from environmental factors, such as moisture and vibration, which can affect their performance. In addition to these areas, adhesive delivery systems are used in various other industries, including construction, packaging, and consumer electronics. In construction, they are used for bonding and sealing applications, such as installing windows, doors, and flooring. In packaging, adhesive delivery systems are used for sealing boxes, cartons, and other packaging materials, ensuring product integrity and safety during transportation. In consumer electronics, these systems are used for assembling devices, such as smartphones, tablets, and wearables, where precision and reliability are critical. The versatility and efficiency of adhesive delivery systems make them indispensable in these diverse applications, driving the growth and development of the Global Adhesive Delivery Systems Market.

Global Adhesive Delivery Systems Market Outlook:

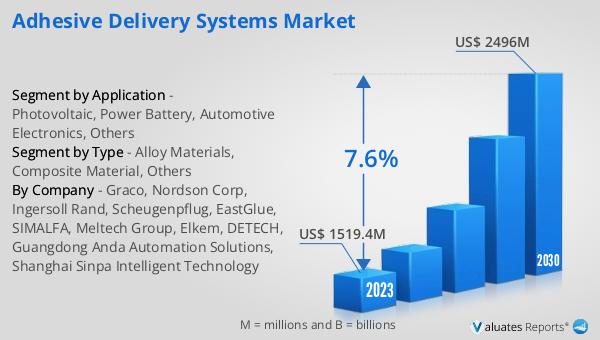

The global Adhesive Delivery Systems market was valued at US$ 1519.4 million in 2023 and is projected to grow significantly, reaching an estimated value of US$ 2496 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 7.6% during the forecast period from 2024 to 2030. The market's expansion is driven by the increasing demand for advanced adhesive solutions across various industries, including automotive, electronics, construction, and packaging. As these industries continue to evolve and innovate, the need for precise, efficient, and reliable adhesive delivery systems becomes more critical. The market's growth is also supported by advancements in adhesive technologies and delivery systems, which are designed to meet the specific requirements of different applications. Additionally, the trend towards automation and the adoption of environmentally friendly adhesive solutions are contributing to the market's positive outlook. As manufacturers seek to improve productivity, reduce waste, and enhance product performance, the Global Adhesive Delivery Systems Market is poised for substantial growth in the coming years.

| Report Metric | Details |

| Report Name | Adhesive Delivery Systems Market |

| Accounted market size in 2023 | US$ 1519.4 million |

| Forecasted market size in 2030 | US$ 2496 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Graco, Nordson Corp, Ingersoll Rand, Scheugenpflug, EastGlue, SIMALFA, Meltech Group, Elkem, DETECH, Guangdong Anda Automation Solutions, Shanghai Sinpa Intelligent Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |