What is Global Polyaspartic Ester Resin Market?

The Global Polyaspartic Ester Resin Market is a vast and dynamic sector that deals with the production, distribution, and consumption of Polyaspartic Ester Resin. This resin is a type of high-performance coating material known for its superior durability, fast curing times, and resistance to weather, UV, and chemicals. The market is driven by various factors such as the growing demand from various end-use industries like building and construction, industrial, transportation, and power generation. However, the market also faces certain challenges such as the high cost of raw materials and stringent environmental regulations. Despite these challenges, the market has shown significant growth over the years and is expected to continue its upward trajectory in the future.

Below 500, 500-1000, Above 1000 in the Global Polyaspartic Ester Resin Market:

The Global Polyaspartic Ester Resin Market is segmented based on viscosity into Below 500, 500-1000, and Above 1000. The 500-1000 segment holds the largest market share, accounting for over 38% of the total market. This is primarily due to the optimal balance of properties that this viscosity range offers, making it suitable for a wide range of applications. On the other hand, the Below 500 and Above 1000 segments also have significant market shares, driven by specific applications that require either low or high viscosity resins. However, data for these segments is currently not available.

Building and Construction, Industrial, Transportation, Power Generation, Others in the Global Polyaspartic Ester Resin Market:

The Global Polyaspartic Ester Resin Market finds extensive usage in various areas such as Building and Construction, Industrial, Transportation, Power Generation, among others. In the Building and Construction sector, the resin is used in applications like flooring, roofing, and waterproofing due to its excellent durability and weather resistance. In the Industrial sector, it is used in protective coatings for machinery and equipment, while in the Transportation sector, it is used in vehicle coatings. In the Power Generation sector, the resin is used in protective coatings for wind turbines and other equipment. Despite its wide range of applications, the market faces certain challenges such as the high cost of the resin and stringent environmental regulations.

Global Polyaspartic Ester Resin Market Outlook:

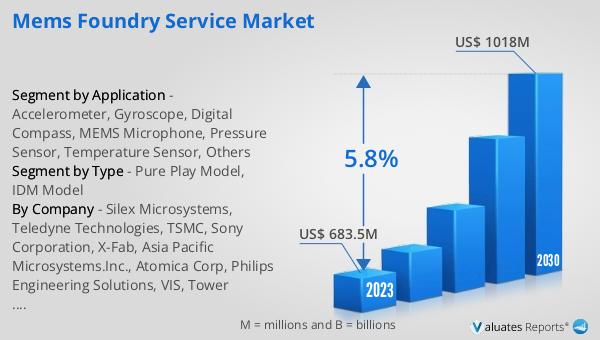

The global Polyaspartic Ester Resin market, valued at US$ 307.9 million in 2022, is projected to reach a value of US$ 493.7 million by 2029. This indicates a Compound Annual Growth Rate (CAGR) of 5.8% during the forecast period of 2023-2029. The largest product segment in terms of viscosity is 500-1000, accounting for over 38% of the market. The largest application segment is building and construction, which holds over 40% of the market share. These figures underscore the significant growth potential of the Polyaspartic Ester Resin market and its importance in various end-use industries.

| Report Metric | Details |

| Report Name | Polyaspartic Ester Resin Market |

| Accounted market size in 2022 | US$ 307.9 million |

| Forecasted market size in 2029 | US$ 493.7 million |

| CAGR | 5.8% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Covestro, Cargill, TSE Industries, Shenzhen Feiyang Protech, Yantai Sunychem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |