What is Global UV Printing UV Sensors Market?

The Global UV Printing UV Sensors Market is a specialized segment within the broader printing and sensor technology industries. This market focuses on the development and distribution of sensors specifically designed to monitor and control ultraviolet (UV) light in printing processes. UV printing is a method that uses UV light to dry or cure ink, adhesives, or coatings almost instantly. This technology is widely used in various printing applications due to its efficiency and ability to produce high-quality prints on a wide range of materials. UV sensors play a crucial role in this process by ensuring that the UV light is at the correct intensity and wavelength to achieve optimal curing. These sensors help in maintaining the quality of the print, reducing waste, and improving the overall efficiency of the printing process. As industries continue to demand faster and more reliable printing solutions, the importance of UV sensors in the printing market is expected to grow. The market for these sensors is driven by advancements in printing technology, increasing demand for high-quality printing, and the need for more sustainable and efficient printing processes.

UVA, UVB, UVC in the Global UV Printing UV Sensors Market:

In the context of the Global UV Printing UV Sensors Market, understanding the different types of UV light—UVA, UVB, and UVC—is essential. UVA, or long-wave ultraviolet light, has the longest wavelength ranging from 320 to 400 nanometers. It is the least harmful and is commonly used in applications such as curing inks and coatings in the printing industry. UVA light penetrates deeper into materials, making it ideal for curing thicker layers of ink or coatings. UVB, or medium-wave ultraviolet light, has a wavelength range of 280 to 320 nanometers. It is more energetic than UVA and is often used in applications requiring faster curing times. However, UVB can be more damaging to materials and requires careful control to prevent degradation. UVC, or short-wave ultraviolet light, has the shortest wavelength, ranging from 100 to 280 nanometers. It is the most energetic and is primarily used for sterilization and disinfection purposes. In the printing industry, UVC is less commonly used due to its potential to damage materials and its limited penetration depth. However, it can be used in specific applications where rapid surface curing is required. The choice of UV light type in printing processes depends on the specific requirements of the application, such as the type of material being printed on, the desired curing speed, and the level of detail required in the print. UV sensors are crucial in these processes as they help monitor and control the intensity and wavelength of the UV light, ensuring optimal curing and print quality. These sensors can detect variations in UV light intensity and adjust the printing process accordingly, preventing issues such as under-curing or over-curing, which can affect the durability and appearance of the print. As the demand for high-quality and efficient printing solutions continues to grow, the role of UV sensors in managing UVA, UVB, and UVC light in printing processes becomes increasingly important. These sensors not only enhance the quality of the final product but also contribute to more sustainable and cost-effective printing operations by reducing waste and energy consumption.

Flatbed Screen Printer, Flatbed Laser Printer, Flatbed Inkjet Printer in the Global UV Printing UV Sensors Market:

The Global UV Printing UV Sensors Market finds significant applications in various types of flatbed printers, including flatbed screen printers, flatbed laser printers, and flatbed inkjet printers. In flatbed screen printers, UV sensors are used to monitor the curing process of UV inks. These printers are commonly used for printing on rigid substrates such as glass, metal, and wood. The UV sensors ensure that the UV light used in the curing process is at the correct intensity and wavelength, which is crucial for achieving high-quality prints with vibrant colors and sharp details. By accurately controlling the curing process, UV sensors help reduce ink wastage and improve the overall efficiency of the printing operation. In flatbed laser printers, UV sensors play a vital role in controlling the exposure of UV light during the printing process. These printers use laser technology to create high-resolution images on various materials. The UV sensors ensure that the UV light is precisely controlled to achieve the desired level of detail and contrast in the print. This is particularly important in applications where fine details and intricate designs are required, such as in the production of signage and promotional materials. In flatbed inkjet printers, UV sensors are used to monitor the curing of UV inks as they are applied to the substrate. These printers are versatile and can print on a wide range of materials, including paper, plastic, and textiles. The UV sensors ensure that the inks are cured quickly and evenly, preventing issues such as smudging or fading. This is essential for producing high-quality prints that are durable and resistant to environmental factors such as UV exposure and moisture. By optimizing the curing process, UV sensors help improve the speed and efficiency of flatbed inkjet printing operations, making them more cost-effective and environmentally friendly. Overall, the use of UV sensors in flatbed printers enhances the quality and efficiency of the printing process, contributing to the growing demand for UV printing solutions in various industries.

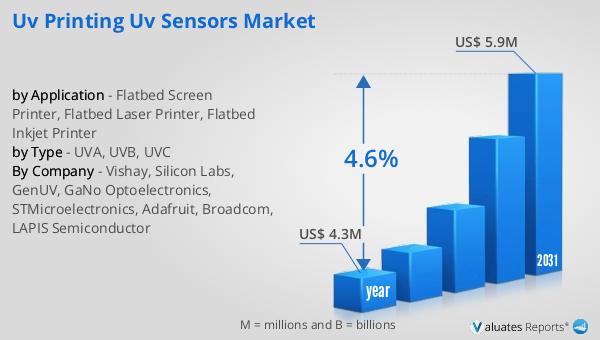

Global UV Printing UV Sensors Market Outlook:

The outlook for the Global UV Printing UV Sensors Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 4.3 million. Looking ahead, it is anticipated to expand to a revised size of US$ 5.9 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend reflects the increasing demand for UV printing technologies across various industries, driven by the need for high-quality, efficient, and sustainable printing solutions. The market's growth is supported by advancements in printing technology, which have enhanced the capabilities and applications of UV printing. As industries continue to seek faster and more reliable printing methods, the role of UV sensors in ensuring optimal curing and print quality becomes increasingly important. These sensors not only improve the efficiency of the printing process but also contribute to reducing waste and energy consumption, aligning with the growing emphasis on sustainability. The projected growth of the Global UV Printing UV Sensors Market underscores the importance of these sensors in modern printing operations and highlights the potential for further innovation and development in this field.

| Report Metric | Details |

| Report Name | UV Printing UV Sensors Market |

| Accounted market size in year | US$ 4.3 million |

| Forecasted market size in 2031 | US$ 5.9 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vishay, Silicon Labs, GenUV, GaNo Optoelectronics, STMicroelectronics, Adafruit, Broadcom, LAPIS Semiconductor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |