What is Global Liquid Molding Compounds (LMC) Market?

The Global Liquid Molding Compounds (LMC) Market is a dynamic and evolving sector within the materials industry, focusing on the production and application of liquid molding compounds. These compounds are essential in various manufacturing processes due to their unique properties, such as high thermal stability, excellent mechanical strength, and superior electrical insulation. LMCs are primarily used in the electronics and automotive industries, where they play a crucial role in the encapsulation and protection of sensitive components. The market is driven by the increasing demand for miniaturized electronic devices and the growing automotive industry, which requires advanced materials for enhanced performance and durability. Additionally, the rise in technological advancements and the need for sustainable and efficient manufacturing processes further propel the growth of the LMC market. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the Global Liquid Molding Compounds Market is poised for significant expansion and development.

Liquid Epoxy Underfill, Liquid Epoxy Encapsulat Material in the Global Liquid Molding Compounds (LMC) Market:

Liquid Epoxy Underfill and Liquid Epoxy Encapsulant Materials are integral components of the Global Liquid Molding Compounds (LMC) Market, serving critical roles in the electronics manufacturing sector. Liquid Epoxy Underfill is primarily used to enhance the mechanical strength and reliability of electronic assemblies, particularly in flip-chip and ball grid array (BGA) packages. It acts as a protective layer that fills the gap between the chip and the substrate, mitigating stress and preventing damage from thermal cycling and mechanical shock. This underfill material is crucial for ensuring the longevity and performance of electronic devices, especially in high-reliability applications such as aerospace and automotive electronics. On the other hand, Liquid Epoxy Encapsulant Materials are used to encapsulate and protect electronic components from environmental factors such as moisture, dust, and chemicals. These materials provide a robust barrier that safeguards sensitive components, ensuring their functionality and reliability in harsh operating conditions. The encapsulants are designed to offer excellent adhesion, thermal stability, and electrical insulation, making them ideal for use in a wide range of electronic applications. The demand for Liquid Epoxy Underfill and Encapsulant Materials is driven by the increasing complexity and miniaturization of electronic devices, which require advanced materials to ensure their performance and reliability. As the electronics industry continues to evolve, the need for high-performance underfill and encapsulant materials is expected to grow, further fueling the expansion of the Global Liquid Molding Compounds Market.

Fan-Out Wafer Level Packaging (FOWLP), Ball Grid Array Package (BGA), Other in the Global Liquid Molding Compounds (LMC) Market:

The Global Liquid Molding Compounds (LMC) Market finds extensive usage in various advanced packaging technologies, including Fan-Out Wafer Level Packaging (FOWLP), Ball Grid Array Package (BGA), and other applications. In Fan-Out Wafer Level Packaging, LMCs are used to create a robust and reliable encapsulation for semiconductor devices. FOWLP is a cutting-edge packaging technology that offers several advantages, such as improved thermal performance, reduced package size, and enhanced electrical characteristics. The use of LMCs in FOWLP ensures the protection of delicate semiconductor components from environmental stressors, thereby enhancing their performance and longevity. In Ball Grid Array Package applications, LMCs play a crucial role in providing mechanical support and protection to the solder joints, which are critical for the electrical connectivity of the package. The use of LMCs in BGA packages helps in mitigating stress and preventing solder joint failures, which can lead to device malfunction. Additionally, LMCs are used in other applications such as encapsulating sensors, connectors, and other electronic components that require protection from environmental factors. The versatility and superior properties of LMCs make them an ideal choice for these applications, ensuring the reliability and performance of electronic devices in various industries. As the demand for advanced packaging technologies continues to rise, the usage of LMCs in these applications is expected to grow, further driving the expansion of the Global Liquid Molding Compounds Market.

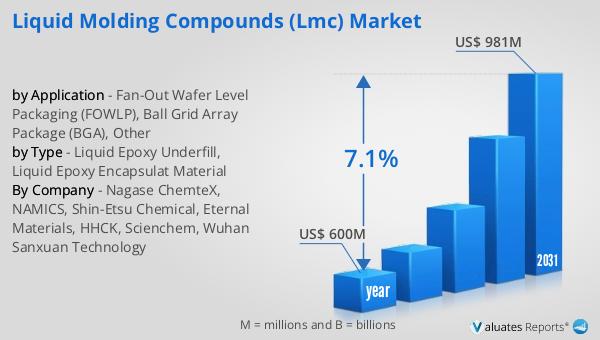

Global Liquid Molding Compounds (LMC) Market Outlook:

The global market for Liquid Molding Compounds (LMC) was valued at approximately $600 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $981 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 7.1% over the forecast period. The increasing demand for LMCs is driven by their critical applications in various industries, including electronics and automotive, where they are used for encapsulation and protection of sensitive components. The market's expansion is also fueled by the rising trend of miniaturization in electronic devices, which necessitates the use of advanced materials like LMCs to ensure performance and reliability. Additionally, the growing emphasis on sustainable and efficient manufacturing processes is contributing to the increased adoption of LMCs. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the Global Liquid Molding Compounds Market is poised for significant growth and development. This positive market outlook underscores the importance of LMCs in modern manufacturing and their potential to drive advancements in various sectors.

| Report Metric | Details |

| Report Name | Liquid Molding Compounds (LMC) Market |

| Accounted market size in year | US$ 600 million |

| Forecasted market size in 2031 | US$ 981 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nagase ChemteX, NAMICS, Shin-Etsu Chemical, Eternal Materials, HHCK, Scienchem, Wuhan Sanxuan Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |