What is Global Industrial Ultrasonic Position Sensor Market?

The Global Industrial Ultrasonic Position Sensor Market is a dynamic and rapidly evolving sector that plays a crucial role in various industrial applications. These sensors use ultrasonic waves to determine the position of an object, making them invaluable in environments where traditional sensors might fail due to dust, moisture, or other challenging conditions. Ultrasonic position sensors are known for their precision and reliability, which makes them ideal for industries such as manufacturing, automotive, and logistics. They are used to measure distance, detect objects, and track positions with high accuracy. The market is driven by the increasing demand for automation and the need for efficient and accurate sensing solutions in industrial processes. As industries continue to embrace automation and smart technologies, the demand for ultrasonic position sensors is expected to grow. These sensors are also gaining popularity due to their non-contact nature, which reduces wear and tear and extends their lifespan. Overall, the Global Industrial Ultrasonic Position Sensor Market is poised for significant growth as industries seek more advanced and reliable sensing technologies to enhance their operations.

Discrete Ultrasonic Position Sensor, Continuous Ultrasonic Position Sensor in the Global Industrial Ultrasonic Position Sensor Market:

Discrete Ultrasonic Position Sensors and Continuous Ultrasonic Position Sensors are two primary types of sensors within the Global Industrial Ultrasonic Position Sensor Market, each serving distinct purposes and applications. Discrete Ultrasonic Position Sensors are designed to detect the presence or absence of an object within a specific range. They are often used in applications where it is essential to know whether an object is present or not, such as in assembly lines or packaging processes. These sensors emit ultrasonic waves and measure the time it takes for the waves to bounce back after hitting an object. If the object is within the predefined range, the sensor triggers a response, such as stopping a conveyor belt or activating an alarm. Discrete sensors are highly reliable and are often used in environments where precision is critical, such as in the automotive industry for detecting the presence of components during assembly. On the other hand, Continuous Ultrasonic Position Sensors provide real-time data on the position of an object within a specified range. Unlike discrete sensors, which only indicate the presence or absence of an object, continuous sensors provide detailed information about the object's position, allowing for more precise control and monitoring. These sensors are commonly used in applications where continuous monitoring is required, such as in robotics, where they help in guiding robotic arms with precision. Continuous sensors are also used in level measurement applications, such as monitoring the fill level of liquids in tanks. By providing continuous data, these sensors enable industries to maintain optimal levels and prevent overflows or shortages. The choice between discrete and continuous sensors depends on the specific requirements of the application. Discrete sensors are ideal for applications where simple presence detection is needed, while continuous sensors are better suited for applications that require detailed position data. Both types of sensors are integral to the Global Industrial Ultrasonic Position Sensor Market, offering solutions that enhance efficiency, accuracy, and reliability in various industrial processes. As industries continue to evolve and demand more sophisticated sensing technologies, the role of both discrete and continuous ultrasonic position sensors is expected to grow, driving innovation and development in the market.

Object Tracking, Fill Level Measurement, Object Detection, Distance Measurement, Others in the Global Industrial Ultrasonic Position Sensor Market:

The Global Industrial Ultrasonic Position Sensor Market finds extensive usage in various applications, including Object Tracking, Fill Level Measurement, Object Detection, Distance Measurement, and others. In Object Tracking, ultrasonic position sensors are used to monitor the movement and position of objects in real-time. This application is particularly useful in logistics and supply chain management, where tracking the movement of goods is crucial for efficient operations. By providing accurate position data, these sensors help in optimizing routes, reducing delays, and improving overall efficiency. In Fill Level Measurement, ultrasonic sensors are used to monitor the level of liquids or solids in tanks and containers. These sensors emit ultrasonic waves that reflect off the surface of the material, allowing for precise measurement of the fill level. This application is widely used in industries such as chemical processing, food and beverage, and water treatment, where maintaining optimal fill levels is essential for efficient operations. Object Detection is another critical application of ultrasonic position sensors. These sensors are used to detect the presence of objects in various industrial processes, such as assembly lines, packaging, and quality control. By providing reliable detection capabilities, ultrasonic sensors help in ensuring that processes run smoothly and efficiently. Distance Measurement is a fundamental application of ultrasonic position sensors, where they are used to measure the distance between the sensor and an object. This application is widely used in industries such as automotive, where precise distance measurement is crucial for applications like parking assistance and collision avoidance. Other applications of ultrasonic position sensors include monitoring the position of moving parts in machinery, detecting the presence of people in security systems, and guiding autonomous vehicles. The versatility and reliability of ultrasonic position sensors make them an essential component in various industrial applications, driving their demand in the Global Industrial Ultrasonic Position Sensor Market.

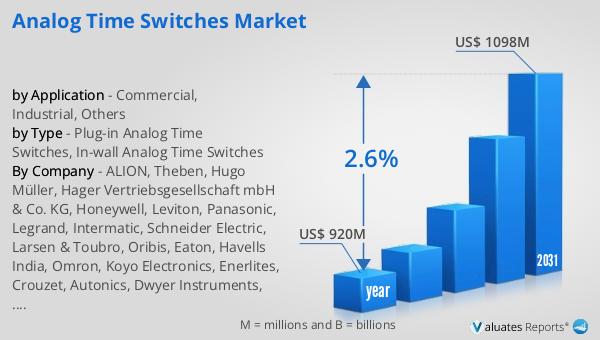

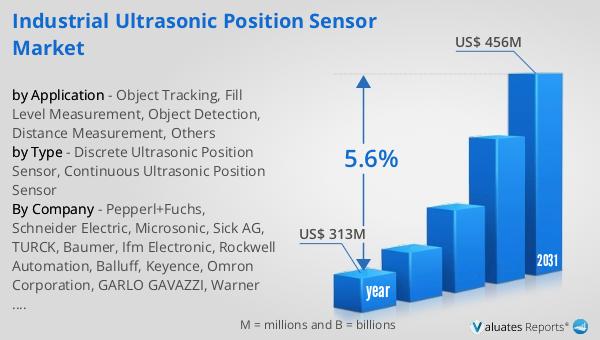

Global Industrial Ultrasonic Position Sensor Market Outlook:

The outlook for the Global Industrial Ultrasonic Position Sensor Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 313 million, and it is projected to expand to a revised size of US$ 456 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.6% during the forecast period. The market's expansion is driven by the increasing demand for advanced sensing technologies in various industries, as well as the growing trend towards automation and smart manufacturing. The market is dominated by the top four manufacturers, who collectively hold a substantial share of over 65%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and technological advancements in maintaining a leading position. Europe emerges as the largest market for industrial ultrasonic position sensors, accounting for nearly 65% of the global market share. This dominance can be attributed to the region's strong industrial base, advanced manufacturing capabilities, and the widespread adoption of automation technologies. As the market continues to evolve, manufacturers are likely to focus on developing more sophisticated and reliable sensors to meet the diverse needs of various industries. The Global Industrial Ultrasonic Position Sensor Market is poised for significant growth, driven by technological advancements, increasing demand for automation, and the need for precise and reliable sensing solutions in industrial applications.

| Report Metric | Details |

| Report Name | Industrial Ultrasonic Position Sensor Market |

| Accounted market size in year | US$ 313 million |

| Forecasted market size in 2031 | US$ 456 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Pepperl+Fuchs, Schneider Electric, Microsonic, Sick AG, TURCK, Baumer, Ifm Electronic, Rockwell Automation, Balluff, Keyence, Omron Corporation, GARLO GAVAZZI, Warner Electric (Altra) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |