What is Global Non-contact Magnetostrictive Position Sensors Market?

The Global Non-contact Magnetostrictive Position Sensors Market is a specialized segment within the broader sensor industry, focusing on devices that utilize magnetostrictive technology to measure position without physical contact. These sensors are renowned for their precision, durability, and reliability, making them ideal for applications where traditional contact-based sensors might fail due to wear and tear. Magnetostrictive position sensors operate by detecting changes in magnetic fields, which are then converted into electrical signals to determine the exact position of an object. This technology is particularly advantageous in environments where cleanliness, precision, and longevity are critical, such as in manufacturing, automation, and various industrial applications. The market for these sensors is driven by the increasing demand for automation and the need for accurate position sensing in complex machinery. As industries continue to evolve and adopt more sophisticated technologies, the role of non-contact magnetostrictive position sensors becomes increasingly vital, offering solutions that enhance efficiency and reduce maintenance costs. The global market is characterized by a diverse range of products catering to different industrial needs, with continuous advancements in technology further propelling its growth.

Analog Type, Digital Type in the Global Non-contact Magnetostrictive Position Sensors Market:

In the realm of Global Non-contact Magnetostrictive Position Sensors, two primary types dominate the market: Analog and Digital. Analog magnetostrictive position sensors are known for their continuous output signal, which is directly proportional to the position of the object being measured. This type of sensor is particularly useful in applications where real-time monitoring and control are essential. Analog sensors provide a smooth and continuous signal, making them ideal for applications requiring precise control, such as in hydraulic systems, robotics, and automated machinery. The analog output can be easily integrated into existing systems, offering a straightforward solution for position sensing. On the other hand, Digital magnetostrictive position sensors offer discrete output signals, which are often more suitable for applications requiring high precision and accuracy. Digital sensors convert the position into a digital signal, which can be easily processed by modern control systems. This type of sensor is particularly advantageous in environments where noise and interference might affect analog signals. Digital sensors are often used in applications where data needs to be transmitted over long distances or where integration with digital control systems is required. The choice between analog and digital sensors often depends on the specific requirements of the application, including factors such as the level of precision needed, the environment in which the sensor will operate, and the existing infrastructure. Both types of sensors offer unique advantages, and the decision to use one over the other is typically based on a careful analysis of the application's needs. As technology continues to advance, the capabilities of both analog and digital magnetostrictive position sensors are expected to improve, offering even greater precision and reliability. The ongoing development in sensor technology is likely to lead to more sophisticated and versatile products, catering to a wider range of industrial applications. The market for these sensors is characterized by a high level of competition, with numerous manufacturers offering a variety of products to meet the diverse needs of different industries. As industries continue to embrace automation and advanced technologies, the demand for both analog and digital magnetostrictive position sensors is expected to grow, driven by the need for accurate and reliable position sensing solutions. The future of the Global Non-contact Magnetostrictive Position Sensors Market looks promising, with continuous advancements in technology and increasing demand for precision and reliability in industrial applications.

Petroleum Industry, Chemical Industry, Pharmaceutical Industry, Food Industry, Other in the Global Non-contact Magnetostrictive Position Sensors Market:

The Global Non-contact Magnetostrictive Position Sensors Market finds extensive usage across various industries, including the Petroleum, Chemical, Pharmaceutical, and Food industries, among others. In the Petroleum industry, these sensors are crucial for monitoring the position of drilling equipment and ensuring precise control over the extraction process. The harsh and demanding environment of oil rigs requires sensors that can withstand extreme conditions while providing accurate and reliable data. Magnetostrictive position sensors are ideal for this purpose, offering durability and precision that are essential for efficient operations. In the Chemical industry, these sensors are used to monitor the position of valves and other critical components in chemical processing plants. The ability to provide accurate position data without physical contact is particularly advantageous in environments where corrosive substances are present. This ensures that the sensors remain operational and reliable, even in challenging conditions. The Pharmaceutical industry also benefits from the use of non-contact magnetostrictive position sensors, particularly in the manufacturing and packaging of pharmaceutical products. These sensors help ensure that machinery operates with precision, reducing the risk of errors and ensuring the quality of the final product. In the Food industry, magnetostrictive position sensors are used to monitor the position of equipment in food processing and packaging lines. The non-contact nature of these sensors makes them ideal for use in environments where hygiene and cleanliness are paramount. By providing accurate position data, these sensors help ensure that food products are processed and packaged efficiently and safely. Beyond these industries, magnetostrictive position sensors are also used in a variety of other applications, including automation, robotics, and manufacturing. Their versatility and reliability make them a valuable tool in any industry where precise position sensing is required. As industries continue to evolve and adopt more advanced technologies, the demand for non-contact magnetostrictive position sensors is expected to grow, driven by the need for accurate and reliable solutions that enhance efficiency and reduce maintenance costs.

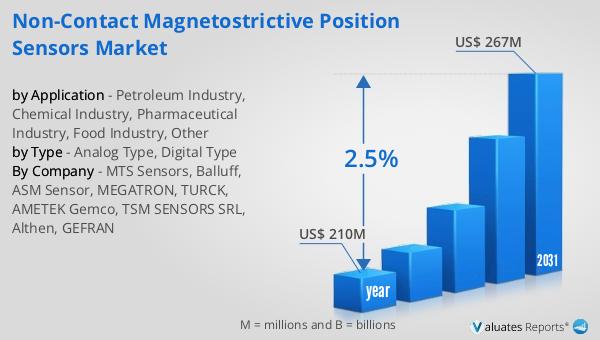

Global Non-contact Magnetostrictive Position Sensors Market Outlook:

In 2024, the global market for Non-contact Magnetostrictive Position Sensors was valued at approximately $210 million. This market is anticipated to expand, reaching an estimated value of $267 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.5% over the forecast period. The steady increase in market size reflects the growing demand for precise and reliable position sensing solutions across various industries. As industries continue to embrace automation and advanced technologies, the need for accurate position sensors becomes increasingly critical. The market's growth is driven by the advantages offered by magnetostrictive technology, including its durability, precision, and ability to operate in harsh environments. These sensors are particularly valuable in industries such as petroleum, chemical, pharmaceutical, and food, where accurate position sensing is essential for efficient operations. The projected growth of the market indicates a positive outlook for the future, with continuous advancements in technology expected to further enhance the capabilities of magnetostrictive position sensors. As the market evolves, manufacturers are likely to develop more sophisticated and versatile products to meet the diverse needs of different industries. The increasing demand for automation and precision in industrial applications is expected to drive the growth of the Global Non-contact Magnetostrictive Position Sensors Market, offering opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Non-contact Magnetostrictive Position Sensors Market |

| Accounted market size in year | US$ 210 million |

| Forecasted market size in 2031 | US$ 267 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTS Sensors, Balluff, ASM Sensor, MEGATRON, TURCK, AMETEK Gemco, TSM SENSORS SRL, Althen, GEFRAN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |