What is Global Bottom Anti-Reflection Coatings (BARC) Market?

Global Bottom Anti-Reflection Coatings (BARC) Market refers to the industry focused on producing and distributing coatings that minimize reflection on surfaces, particularly in semiconductor manufacturing. These coatings are crucial in the photolithography process, a key step in semiconductor fabrication, where they help improve the accuracy and efficiency of pattern transfer onto silicon wafers. By reducing reflections, BARC enhances the resolution and precision of the photolithographic process, leading to better performance and yield of semiconductor devices. The market for BARC is driven by the increasing demand for advanced electronic devices, which require highly efficient and precise semiconductor components. As technology advances, the need for more sophisticated and smaller semiconductor devices grows, further propelling the demand for effective anti-reflection coatings. The market encompasses various types of BARC, including organic and inorganic variants, each offering distinct advantages depending on the specific application requirements. The growth of the BARC market is closely tied to the overall expansion of the semiconductor industry, which is fueled by the proliferation of consumer electronics, automotive electronics, and other high-tech applications. As a result, the BARC market is expected to continue evolving, driven by technological advancements and the increasing complexity of semiconductor devices.

Organic Type, Inorganic Type in the Global Bottom Anti-Reflection Coatings (BARC) Market:

In the Global Bottom Anti-Reflection Coatings (BARC) Market, coatings are categorized into two main types: organic and inorganic. Organic BARC is primarily composed of carbon-based materials, which offer flexibility and ease of application. These coatings are typically used in applications where a high degree of customization is required, as they can be tailored to meet specific optical and mechanical properties. Organic BARCs are known for their excellent adhesion properties and compatibility with various substrates, making them a popular choice in the semiconductor industry. They are particularly effective in reducing reflections in the deep ultraviolet (DUV) and extreme ultraviolet (EUV) lithography processes, which are essential for manufacturing advanced semiconductor devices. On the other hand, inorganic BARC is made from metal oxides or other inorganic compounds, providing superior thermal stability and durability. These coatings are ideal for applications that require high resistance to heat and chemical exposure, such as in power-chip semiconductors and other high-performance electronic components. Inorganic BARCs are often used in environments where long-term reliability and performance are critical, as they can withstand harsh conditions without degrading. The choice between organic and inorganic BARC depends on the specific requirements of the application, including factors such as the wavelength of light used in the lithography process, the type of substrate, and the desired performance characteristics. Both types of BARC play a crucial role in enhancing the efficiency and precision of semiconductor manufacturing, contributing to the overall growth and development of the semiconductor industry. As technology continues to advance, the demand for both organic and inorganic BARC is expected to increase, driven by the need for more sophisticated and efficient semiconductor devices.

Memory, Power-chip Semiconductors, Others in the Global Bottom Anti-Reflection Coatings (BARC) Market:

The Global Bottom Anti-Reflection Coatings (BARC) Market finds significant usage in various areas, including memory, power-chip semiconductors, and other applications. In the memory sector, BARC is essential for improving the performance and reliability of memory chips, which are critical components in a wide range of electronic devices. By minimizing reflections during the photolithography process, BARC enhances the precision of pattern transfer, leading to higher density and more efficient memory chips. This is particularly important in the production of advanced memory technologies, such as DRAM and NAND flash, where precision and efficiency are paramount. In power-chip semiconductors, BARC plays a crucial role in ensuring the reliability and performance of power management devices, which are used in various applications, including automotive electronics, industrial equipment, and consumer electronics. The use of BARC in power-chip semiconductors helps improve the thermal stability and durability of these devices, enabling them to operate efficiently under high-stress conditions. Additionally, BARC is used in other semiconductor applications, such as sensors, microprocessors, and communication devices, where it contributes to the overall performance and efficiency of the devices. The versatility and effectiveness of BARC in enhancing the precision and efficiency of semiconductor manufacturing make it an indispensable component in the production of advanced electronic devices. As the demand for more sophisticated and efficient electronic devices continues to grow, the usage of BARC in various applications is expected to increase, driving the overall growth of the BARC market.

Global Bottom Anti-Reflection Coatings (BARC) Market Outlook:

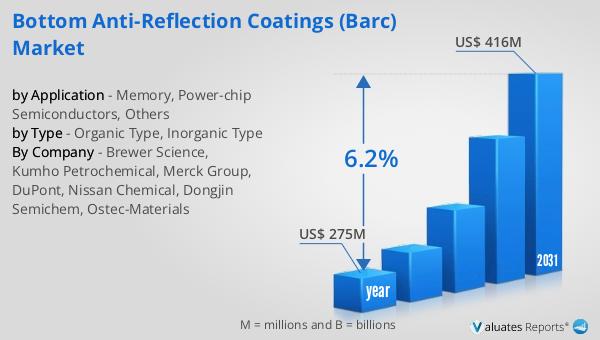

The global market for Bottom Anti-Reflection Coatings (BARC) was valued at $275 million in 2024, with projections indicating a growth to $416 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. The increasing demand for advanced semiconductor devices, driven by the proliferation of consumer electronics, automotive electronics, and other high-tech applications, is a key factor contributing to the growth of the BARC market. As technology continues to advance, the need for more sophisticated and efficient semiconductor components becomes increasingly important, further propelling the demand for effective anti-reflection coatings. The market for BARC is expected to continue evolving, driven by technological advancements and the increasing complexity of semiconductor devices. The growth of the BARC market is closely tied to the overall expansion of the semiconductor industry, which is fueled by the proliferation of consumer electronics, automotive electronics, and other high-tech applications. As a result, the BARC market is expected to continue evolving, driven by technological advancements and the increasing complexity of semiconductor devices. The growth of the BARC market is closely tied to the overall expansion of the semiconductor industry, which is fueled by the proliferation of consumer electronics, automotive electronics, and other high-tech applications. As a result, the BARC market is expected to continue evolving, driven by technological advancements and the increasing complexity of semiconductor devices.

| Report Metric | Details |

| Report Name | Bottom Anti-Reflection Coatings (BARC) Market |

| Accounted market size in year | US$ 275 million |

| Forecasted market size in 2031 | US$ 416 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Brewer Science, Kumho Petrochemical, Merck Group, DuPont, Nissan Chemical, Dongjin Semichem, Ostec-Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |