What is Global Powder Coating Service Market?

The Global Powder Coating Service Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. Powder coating is a dry finishing process that has become extremely popular since its introduction in North America in the 1960s. It represents over 15% of the total industrial finishing market. The process involves applying a free-flowing, dry powder to a surface, which is then cured under heat to form a skin-like coating. This method is favored for its durability, high-quality finish, and environmental benefits, as it emits negligible volatile organic compounds (VOCs). The global market for powder coating services is driven by increasing demand from industries such as automotive, appliances, furniture, electronics, and architectural parts. These sectors require coatings that provide superior resistance to corrosion, chemicals, and weathering, while also offering aesthetic appeal. The market is characterized by technological advancements, with companies continually innovating to improve the efficiency and effectiveness of powder coating processes. As industries strive for more sustainable and cost-effective solutions, the demand for powder coating services is expected to grow, making it a vital component of the global manufacturing landscape.

Thermosetting Powder, Thermoplastic Powder in the Global Powder Coating Service Market:

In the realm of the Global Powder Coating Service Market, two primary types of powders are utilized: thermosetting and thermoplastic powders. Each type has distinct characteristics and applications, catering to different industrial needs. Thermosetting powders are composed of a base resin, curing agents, pigments, and additives. When heated, these powders undergo a chemical reaction that forms a cross-linked, irreversible bond, resulting in a hard, durable finish. This type of powder is widely used due to its excellent adhesion, chemical resistance, and ability to withstand high temperatures. Common resins used in thermosetting powders include epoxy, polyester, and acrylic. Epoxy powders are known for their superior corrosion resistance and are often used in environments where protection against harsh chemicals is essential. Polyester powders, on the other hand, offer excellent weatherability and UV resistance, making them ideal for outdoor applications. Acrylic powders provide a high-gloss finish and are often used in applications where aesthetics are a priority. Thermoplastic powders, in contrast, do not undergo a chemical change when heated. Instead, they melt and flow to form a coating, which hardens upon cooling. This process is reversible, allowing the coating to be remelted and reshaped if necessary. Thermoplastic powders are known for their toughness, flexibility, and impact resistance. They are often used in applications where a thick, protective layer is required, such as in automotive parts and industrial equipment. Common thermoplastic resins include polyethylene, polyvinyl chloride (PVC), and nylon. Polyethylene powders are valued for their chemical resistance and are often used in coatings for pipes and tanks. PVC powders offer excellent abrasion resistance and are commonly used in coatings for wire and cable insulation. Nylon powders provide a smooth, durable finish and are often used in applications where low friction and wear resistance are important. Both thermosetting and thermoplastic powders offer unique advantages, and the choice between them depends on the specific requirements of the application. Factors such as the desired finish, environmental conditions, and mechanical properties all play a role in determining the most suitable powder for a given project. As the Global Powder Coating Service Market continues to grow, advancements in powder technology are expected to further enhance the performance and versatility of these coatings, opening up new possibilities for their use across a wide range of industries.

Automotive, Appliances, Furniture, Electronics, Industrial Equipment, Architectural Parts in the Global Powder Coating Service Market:

The Global Powder Coating Service Market finds extensive application across various sectors, each with its unique requirements and challenges. In the automotive industry, powder coating is used to provide a durable, high-quality finish to a wide range of components, from wheels and bumpers to engine parts and frames. The coatings offer excellent resistance to corrosion, chemicals, and weathering, ensuring that vehicles maintain their appearance and performance over time. In the appliances sector, powder coating is used to enhance the durability and aesthetics of products such as refrigerators, washing machines, and ovens. The coatings provide a smooth, attractive finish that is resistant to scratches, stains, and heat, ensuring that appliances remain functional and visually appealing throughout their lifespan. In the furniture industry, powder coating is used to provide a durable, attractive finish to metal and wood furniture. The coatings offer excellent resistance to wear and tear, ensuring that furniture maintains its appearance and functionality over time. In the electronics sector, powder coating is used to protect sensitive components from damage due to moisture, chemicals, and electrical interference. The coatings provide a durable, insulating layer that helps to extend the lifespan of electronic devices and improve their performance. In the industrial equipment sector, powder coating is used to provide a tough, protective layer to machinery and equipment. The coatings offer excellent resistance to abrasion, chemicals, and weathering, ensuring that equipment remains operational and efficient in harsh environments. In the architectural parts sector, powder coating is used to provide a durable, attractive finish to building components such as window frames, doors, and facades. The coatings offer excellent resistance to UV radiation, corrosion, and weathering, ensuring that buildings maintain their appearance and structural integrity over time. Across all these sectors, the Global Powder Coating Service Market plays a crucial role in enhancing the durability, performance, and aesthetics of products, making it an essential component of modern manufacturing.

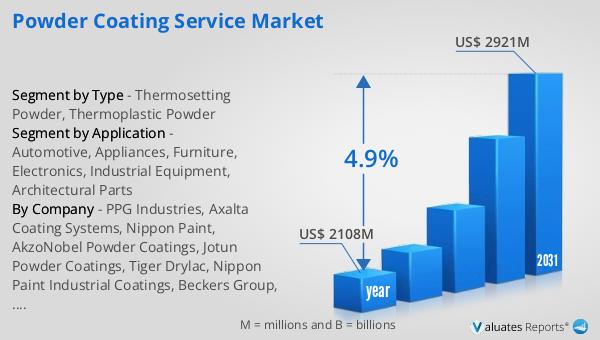

Global Powder Coating Service Market Outlook:

The global market for powder coating services was valued at $2,108 million in 2024, and it is anticipated to expand to a revised size of $2,921 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period. This growth trajectory underscores the increasing demand for powder coating services across various industries. The market's expansion is driven by the need for durable, high-quality finishes that offer superior resistance to corrosion, chemicals, and weathering. As industries continue to seek sustainable and cost-effective solutions, powder coating services are becoming an increasingly attractive option. The market's growth is also supported by technological advancements, with companies continually innovating to improve the efficiency and effectiveness of powder coating processes. As a result, the global powder coating service market is poised for significant growth in the coming years, making it a vital component of the global manufacturing landscape. The projected growth of the market highlights the importance of powder coating services in enhancing the durability, performance, and aesthetics of products across a wide range of industries. As the market continues to evolve, it is expected to open up new opportunities for innovation and expansion, further solidifying its position as a key player in the global manufacturing sector.

| Report Metric | Details |

| Report Name | Powder Coating Service Market |

| Accounted market size in year | US$ 2108 million |

| Forecasted market size in 2031 | US$ 2921 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | PPG Industries, Axalta Coating Systems, Nippon Paint, AkzoNobel Powder Coatings, Jotun Powder Coatings, Tiger Drylac, Nippon Paint Industrial Coatings, Beckers Group, Powder Coating Services, Inc, PowderCoat Services, TCI Powder Coatings, Xometry, VITRACOAT, American Powder Coatings, Advanced Plating Technologies, ST Powder Coatings, Sherwin-Williams |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |